Q&A About "Product & Manufacturing"

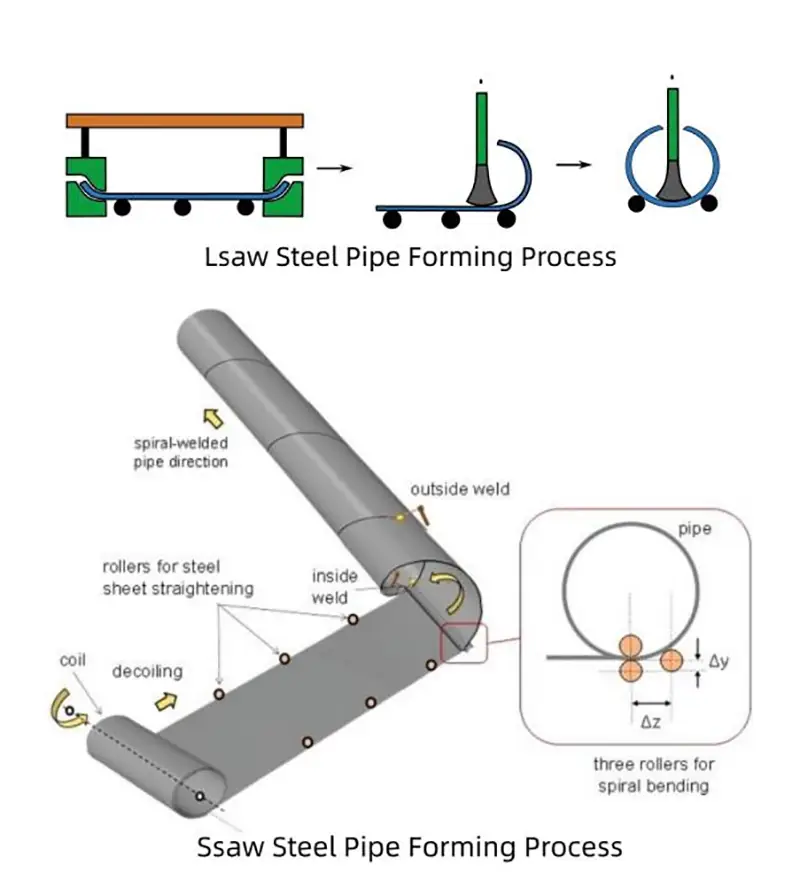

One of the most frequent and important questions our clients, from procurement managers to project engineers, ask is: “What is the real difference between LSAW and SSAW pipe?” While both are types of Submerged Arc Welded (SAW) pipes, their manufacturing methods are fundamentally different, leading to distinct performance characteristics and ideal applications.

As specialists in welded pipe, we believe an informed choice is a smart choice. Our goal is to provide a clear, practical comparison to help you determine which pipe is the optimal solution for your project’s specific needs.

The Core Distinction: How They Are Made

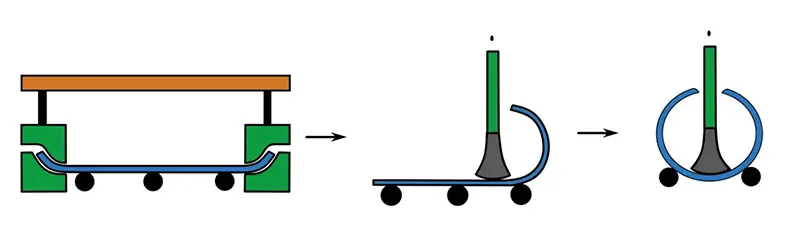

The primary difference between LSAW and SSAW pipe lies in their forming process and raw material format. This initial distinction dictates almost all other characteristics.

- LSAW (Longitudinal SAW) Pipe: Is manufactured from a single, discrete steel plate. The plate is formed into a cylinder, and the seam is welded straight along the length of the pipe. Think of it like rolling a rectangular sheet of paper into a tube and taping the straight edge.

- SSAW (Spiral SAW) Pipe: Is manufactured from a continuous steel coil. The coil is unwound and formed into a cylinder in a spiral or helical fashion, much like the cardboard tube in a roll of paper towels. The weld seam spirals around the pipe.

This fundamental difference in manufacturing is the key to understanding their respective strengths and weaknesses.

Head-to-Head Comparison: Performance and Application

Let’s break down how these manufacturing differences translate into real-world performance.

1. Weld Seam Characteristics

The weld seam is a critical structural component of the pipe.

- LSAW: Features a short, straight weld seam. From a risk management perspective, this presents a simpler and more reliable inspection profile for NDT. The residual stress from the welding process is also lower and more localized.

- SSAW: Has a long, helical weld that can be longer than the pipe itself. This can be a point of higher stress concentration, and the complex geometry can make comprehensive NDT inspection more challenging.

2. Dimensional Accuracy

In pipeline construction, precise dimensions are essential for efficient installation.

- LSAW: The JCOE process, particularly the mechanical expansion stage, gives LSAW pipes superior dimensional tolerance, including excellent roundness and straightness.

- SSAW: The spiral forming process, which relies on a continuous coil, can sometimes result in less precise dimensional control compared to the discrete plate method of LSAW.

3. Production Range and Cost-Effectiveness

The choice often involves a trade-off between the high-efficiency production of SSAW and the high-specification capability of LSAW.

- LSAW: Excels at producing pipes with very large diameters and, most notably, heavy wall thicknesses. The process is more meticulous and generally has a higher cost per ton.

- SSAW: Is a highly efficient process, capable of producing a very wide range of diameters from a single width of steel coil. This often makes it a more cost-effective choice for applications where its performance is sufficient.

4. Mechanical Performance

- LSAW: The use of single steel plates ensures high uniformity and consistency in the base material. This, combined with the verified integrity of its straight weld, makes LSAW the gold standard for high-pressure, mission-critical applications.

- SSAW: The helical weld can effectively distribute line stress. However, for critical high-pressure service, the longer weld seam and potential for variations within a steel coil are key considerations that must be carefully evaluated by project engineers.

Summary Table: LSAW vs. SSAW at a Glance

| Attribute | LSAW (Longitudinal) | SSAW (Spiral/Helical) |

| Raw Material | Single Steel Plate | Steel Coil |

| Weld Seam | Straight, short, parallel to pipe axis | Spiral, long, helical around pipe axis |

| Dimensional Accuracy | Excellent | Good to Standard |

| Wall Thickness | Ideal for heavy and extra-heavy walls | Standard to medium walls |

| Typical Application | High-pressure oil & gas, offshore, sour service | Low/medium-pressure water, structural, piling |

| Key Advantage | High integrity, heavy-wall capability | Cost-effectiveness, wide diameter range |

The Allland Steel Recommendation: Choosing the Right Pipe

There is no single “best” pipe—only the most appropriate pipe for a specific application. Our guidance is straightforward:

- For mission-critical applications involving high pressure, heavy walls, sour service, offshore placement, or where long-term integrity is the absolute priority, LSAW pipe is the superior and necessary choice.

- For general applications such as low-to-medium pressure water transmission, structural piling, or where cost-effectiveness for large diameters is a primary driver, SSAW pipe is often an excellent and suitable solution.

The team at Allland Steel is here to help you navigate these choices. We encourage you to contact us to discuss your project’s specific technical and commercial requirements to ensure you get the optimal piping solution.

Explore our LSAW Pipe and SSAW Pipe product pages for detailed specifications.

Or Contact a Specialist at Allland Steel for a personalized consultation.

In the world of industrial pipes, many options exist, and a common question our clients ask is why LSAW (Longitudinal Submerged Arc Welded) pipe is so often specified for the most critical projects. While other pipes like SSAW or ERW certainly have their place, when you enter the realm of high-pressure, high-stakes applications, the advantages of LSAW pipe are not just beneficial—they are irreplaceable.

Our goal here is to move beyond simple definitions and explain the core engineering and material science principles that make LSAW the definitive choice for projects where performance and safety are non-negotiable.

It Starts with the Foundation: Superior Raw Material and Forming

A critical factor that is often overlooked is that the final quality of a pipe is predetermined by its raw material and forming method. LSAW pipe production begins with a single, discrete hot-rolled steel plate.

From a materials science perspective, this is a significant advantage. A single plate has more consistent mechanical properties and a cleaner, more uniform internal structure compared to the steel coils used for other welded pipes. This inherent material integrity is the foundation upon which all other performance benefits are built.

Key Advantages of LSAW Pipes in Demanding Scenarios

Here are the specific, performance-driven advantages that make LSAW pipe the superior choice for high-end applications.

1. Unmatched Weld Integrity and Safety

The weld is the heart of any welded pipe. The LSAW pipe features a single, straight, and relatively short weld seam. In practice, this simple geometry provides two profound benefits:

- Minimalist Weld Seam: It presents the shortest possible weld path, statistically reducing the chance of any imperfections.

- Reliable Inspection: The straight seam is ideal for precise and highly reliable Non-Destructive Testing (NDT), such as ultrasonic and X-ray inspection. This allows us to guarantee a level of weld integrity that is difficult to achieve with the long, helical seam of an SSAW pipe.

2. Exceptional Dimensional Accuracy

For engineers and on-site crews, dimensional stability is crucial. Thanks to the JCOE forming process and particularly the mechanical expansion stage, LSAW pipes exhibit outstanding roundness, straightness, and uniform diameter. In a real-world scenario, this translates directly to:

- Faster project timelines due to easier fit-up and welding.

- Lower labor costs associated with rework and adjustments.

- Better flow dynamics within the finished pipeline.

3. Unrivaled Capability for Heavy-Wall and High-Grade Steel

When a project requires pushing the boundaries of pressure and depth, heavy-wall pipe is essential. The JCOE manufacturing process is uniquely capable of forming extremely thick steel plates into pipes—a feat that is technically and economically challenging for coil-based methods. This allows us to produce LSAW pipes with significant wall thickness, perfectly suited for deepwater, offshore, and high-pressure gas applications. Furthermore, this process is ideal for use with high-grade steels like X70, X80, and beyond, meeting the demands of modern energy transportation.

4. Superior Performance in Sour Service (H₂S Environments)

For our clients in the oil and gas sector, sour service performance is a primary concern. The clean steel from single plates and the stable, stress-relieved condition of LSAW pipe (thanks to mechanical expansion) give it superior resistance to Hydrogen-Induced Cracking (HIC) and Sulfide Stress Cracking (SSC). This is a critical safety and performance feature for transporting sour crude oil and natural gas.

The Allland Steel Verdict: The Right Pipe for the Mission

Our role as specialists is not just to sell pipes, but to help you match the right product to your project’s specific demands. While ERW pipes are excellent for low-pressure applications and SSAW pipes offer a cost-effective solution for large-diameter, low-pressure lines, the evidence is clear.

For mission-critical infrastructure where long-term safety, reliability, and performance are paramount, LSAW pipe is the only choice.

To explore the technical specifications of our products, please view our LSAW Pipe Product Page.

Or Contact a Specialist at Allland Steel to discuss the unique requirements of your project

In high-stakes industries like oil & gas or offshore construction, where project specifications are demanding and failure is not an option, the choice of line pipe is a critical engineering decision. From our extensive experience, LSAW (Longitudinal Submerged Arc Welded) pipe is the premier choice for these applications. Its superior performance, however, is not a given—it is forged through a precise and advanced production method: the JCOE process.

To truly appreciate the quality of a premium LSAW pipe, it’s essential to understand the engineering that goes into it. This article will provide a clear, expert overview of the JCOE process, explaining how each meticulous step contributes to the final product’s integrity and reliability.

What is the JCOE Process?

The name JCOE is a mnemonic for the core mechanical steps that transform a flat steel plate into a high-performance pipe: J-ing, C-ing, O-ing, and Expanding.

At its core, the JCOE process is a highly controlled method of progressive forming. Unlike other methods that might introduce unpredictable stresses, this process is designed for precision and stability. The key takeaway for our clients is that this method produces a pipe with exceptional dimensional accuracy and uniform material properties from start to finish.

The JCOE Process in Detail: An Engineering Walkthrough

Every LSAW pipe we produce follows a rigorously controlled manufacturing journey. A critical factor that is often overlooked is how these initial steps directly impact the final quality.

Step 1: Plate Edge Milling & Pre-Bending

A flawless weld begins with a perfect edge. This is a non-negotiable first step where we utilize high-precision milling machines to prepare the long edges of the steel plate. This ensures the edges are perfectly parallel and profiled, which is a prerequisite for a sound weld. Following this, the edges are pre-bent. From an engineering perspective, this prevents the formation of sharp “peaks” at the seam during final forming, ensuring a smooth, uniform curvature across the pipe’s entire circumference.

Step 2: J-C-O Forming

This is the heart of the shaping process, where raw geometry is turned into a cylindrical form. The plate moves through a sequence of powerful hydraulic presses:

- J-ing Press: One side of the plate is pressed into a “J” shape.

- C-ing Press: The opposite side is then formed, creating a “C” shape.

- O-ing Press: The pipe is closed into its final “O” shape within a set of dies, ensuring a tight and uniform seam gap for welding.

Step 3: Tack Welding & Internal/External Welding

Our commitment to weld integrity is absolute. The formed pipe is first tack-welded to secure its geometry. Then, the primary welding is performed using the Submerged Arc Welding (SAW) process, renowned for its stability and quality. We perform this both internally and externally to guarantee a full-penetration weld with exceptional strength and uniformity.

Step 4: Mechanical Expanding (The “E” Step)

This is arguably the most critical stage that sets JCOE-manufactured pipes apart. The welded pipe is fitted with an internal expander head. This head applies immense, uniform pressure from the inside out, slightly expanding the pipe’s diameter. The benefits of this step are significant:

- Stress Relief: It effectively neutralizes the internal stresses that accumulate during the forming and welding stages.

- Dimensional Perfection: It guarantees a superior level of roundness and straightness, which is critical for efficient on-site welding and installation.

- Property Enhancement: The process results in a pipe that is not only strong but also incredibly stable and reliable under pressure.

Step 5: Hydrostatic Testing & Non-Destructive Testing (NDT)

Verification is not just a final step; it’s an ongoing philosophy. Every single pipe is subjected to a hydrostatic test, pressurizing it well beyond its operational limits to confirm its strength. The entire weld seam also undergoes 100% NDT inspection, typically using Ultrasonic and X-ray methods, to detect any imperfections invisible to the human eye.

Step 6: Pipe End Beveling & Final Inspection

Finally, the pipe ends are beveled to exact specifications. This ensures that when the pipe arrives at the construction site, it is ready for seamless integration and efficient welding, saving valuable project time. A final visual and dimensional check confirms that the product meets every aspect of the required standard.

How the JCOE Process Fundamentally Guarantees Superior LSAW Pipe Quality

So, what does this highly controlled process mean for your project? The advantages are clear and direct:

- ✅ Predictable, High-Precision Dimensions: For engineers and installers, this means faster fit-up, less on-site fabrication, and more reliable welds.

- ✅ Enhanced Mechanical Reliability: The stress-relieved and dimensionally stable pipe provides a higher margin of safety and a longer service life, especially under cyclic or high-pressure loads.

- ✅ Flawless Weld Integrity: With a 100% inspected, double-sided SAW weld, you can have absolute confidence in the pipeline’s core strength.

- ✅ Capability for Demanding Specifications: The JCOE process is the definitive method for producing the heavy-wall, large-diameter, high-grade pipes required for the world’s most challenging energy and infrastructure projects.

Choose Allland steel, Choose Confidence

We believe an informed client is our best partner. Understanding the intricacies of the JCOE process helps you appreciate the value and reliability built into every LSAW pipe we deliver.

If you have further technical questions or wish to discuss how our manufacturing capabilities can meet the specific demands of your project, our team of specialists is ready to assist.

Learn more about our LSAW Pipe Products.

Or Contact Us Directly for a professional consultation and quote.

A frequent and essential question we receive from project planners and engineers relates to the specific manufacturing capabilities of our LSAW pipe mills. Understanding these parameters is key to aligning our production strengths with your project’s unique engineering and design requirements.

At Allland Steel, our significant investment in modern JCOE (J-ing, C-ing, O-ing, Expanding) manufacturing technology allows us to produce a comprehensive range of high-specification LSAW pipes. Below is a detailed outline of our standard production capabilities.

Core Production Capability Overview

It’s important to view this data as a general guide to our capabilities. We often have the flexibility to produce non-standard or custom dimensions to meet specific project demands.

| Parameter | Specification Range | Notes |

| Outer Diameter (OD) | 406.4 mm – 1524 mm (16″ – 60″) | Continuous range available. |

| Wall Thickness (WT) | 6.0 mm – 60.0 mm (1/4″ – 3″) | Heavy-wall capability is a key strength. |

| Length | 3.0 m – 12.5 m (10” – 40”) | Can be customized based on project needs. |

| Steel Standards | API、ISO、EN、ASTM、DIN、JIS、GB、CSA、GOST | Comprehensive international standard compliance. |

Beyond the Numbers: What Our Capabilities Mean for Your Project

While the figures provide a technical summary, the real value lies in what they enable you to achieve.

Large Diameter and Heavy Wall Thickness

Our ability to produce pipes with substantial diameters and heavy wall thicknesses is critical for projects where high pressure and significant external loads are primary design concerns. This makes our LSAW pipes the ideal solution for:

- High-pressure natural gas transmission mainlines.

- Deepwater and offshore pipelines.

- Large-scale structural components for bridges, stadiums, and offshore platforms.

High-Grade Steel (Up to X70)

From a project economics perspective, utilizing high-grade steel like API 5L X70 can lead to significant advantages. A higher-grade material allows for a reduced wall thickness while maintaining the same pressure rating. This results in:

- A lighter pipe, reducing material tonnage and cost.

- Lower transportation and handling expenses.

- Reduced welding time and material consumption on site.

A core principle at Allland Steel is that our quality control standards are absolute. Every pipe, regardless of its dimensions or steel grade, undergoes the same rigorous inspection and testing regimen, including hydrostatic testing and 100% NDT on the weld seam.

Discuss Your Project with Our Specialists

The specifications listed above represent our standard capabilities, but we often work with clients to develop solutions for unique and challenging projects. The best way to confirm our ability to meet your specific requirements is to connect with our team.

We are ready to review your technical specifications and provide a detailed manufacturing plan that aligns with your project’s goals and timeline.

For more detailed information, please review the technical data on our LSAW Pipe Product Page.

Or Contact a Specialist at Allland Steel to discuss your specific manufacturing needs.

Selecting the right anti-corrosion coating is one of the most critical decisions in ensuring a pipeline’s long-term integrity and service life. A common and important choice our clients face is between two premier coating systems: 3LPE and 3LPP.

While both are advanced, three-layer systems that offer exceptional protection, they are not interchangeable. They are engineered for different operational challenges. Our goal is to clarify these differences, enabling you to make the most reliable and cost-effective choice for your project.

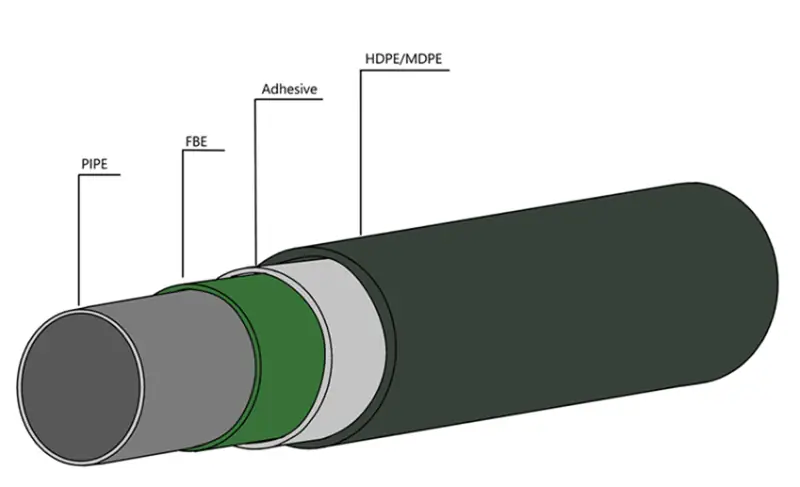

Understanding the Shared “Three-Layer” Foundation

First, it’s important to understand what the “3L” signifies. Both 3LPE and 3LPP share the same fundamental, high-performance structure:

- Layer 1: Fusion Bonded Epoxy (FBE): This primer layer is applied directly to the blasted steel surface. Its primary role is to provide excellent adhesion and act as the main barrier against corrosion.

- Layer 2: Copolymer Adhesive: This functions as the “glue,” creating a strong, chemical bond between the epoxy layer and the final topcoat.

- Layer 3: Polyolefin Topcoat: This is the outer layer that provides robust mechanical protection.

The only difference between 3LPE and 3LPP lies in the material used for this crucial third layer: Polyethylene (PE) or Polypropylene (PP). This single difference, however, dramatically changes the coating’s performance profile.

Head-to-Head: 3LPE (Polyethylene) vs. 3LPP (Polypropylene)

Let’s compare the two systems based on the factors that matter most in project design and execution.

1. Operating Temperature Resistance: The Deciding Factor

From an engineering standpoint, the operational temperature of the pipeline is the single most important factor in this decision.

- 3LPE: Is the industry standard for pipelines operating at normal temperatures. It provides reliable performance for continuous service up to 80-85°C (176-185°F).

- 3LPP: Is specifically engineered for high-temperature applications. The polypropylene topcoat gives it a significantly higher temperature resistance, making it suitable for continuous service up to 110°C (230°F) and even higher for specialized formulations.

A key principle in pipeline design is that exceeding a coating’s temperature limit can lead to accelerated aging and premature failure.

2. Mechanical Properties: Hardness and Abrasion Resistance

The outer layer must protect the pipe from damage during transportation, installation, and throughout its service life.

- 3LPP: Polypropylene is an inherently harder and more rigid material than polyethylene. This gives 3LPP superior resistance to abrasion, impact, gouging, and penetration.

- 3LPE: Offers excellent mechanical protection for most standard conditions but is a slightly softer and more flexible material.

This makes 3LPP the preferred choice for challenging installation environments, such as rocky terrains, horizontal directional drilling (HDD), or areas with significant soil stress.

Summary Table: Key Differences at a Glance

| Property | 3LPE (Three-Layer Polyethylene) | 3LPP (Three-Layer Polypropylene) |

| Max. Operating Temp. | ~85°C (185°F) | >110°C (230°F) |

| Mechanical Resistance | Excellent | Superior (Harder, more abrasion resistant) |

| Flexibility | More Flexible | More Rigid |

| Typical Application | Standard onshore/offshore oil & gas, water | High-temp pipelines, harsh terrains (HDD) |

| Relative Cost | Standard | Higher |

The Allland Steel Recommendation: Which Coating Is Right for You?

Our guidance for choosing between these two excellent systems is clear and based on your project’s specific needs:

- Choose 3LPE if: Your pipeline’s continuous operating temperature will remain below 80°C, and the installation environment is not exceptionally harsh. For a vast majority of oil, gas, and water pipelines, 3LPE provides the optimal balance of high performance, reliability, and cost-effectiveness.

- Choose 3LPP if: Your pipeline will operate at elevated temperatures (above 80°C), will be installed in a challenging or rocky environment, or requires the absolute maximum in mechanical damage resistance. While 3LPP has a higher upfront cost, it is a value-driven investment for projects where its superior resistance prevents costly future repairs and ensures long-term asset integrity.

The selection of a coating system has lasting implications. The specialists at Allland Steel can help you analyze your project’s operational data to make the most reliable and effective choice.

To learn more about our coating capabilities, please Contact a Specialist at Allland Steel.

While multi-layer systems like 3LPE often take the spotlight in conversations about pipeline protection, it would be a mistake to overlook the robust, reliable, and versatile performance of Fusion Bonded Epoxy (FBE) coatings. For decades, FBE has been a cornerstone of industrial anti-corrosion, and from an engineering perspective, it remains the optimal and preferred choice for a number of critical applications.

This guide will clarify the primary uses for FBE, helping you understand where this powerful single-layer system provides the most value.

What is an FBE Coating? A Quick Overview

Before diving into applications, it’s important to understand what FBE is. It is a thermosetting powder that is electrostatically applied to a heated steel surface. The powder melts, flows, and cures, forming a hard, cross-linked film.

The key to its performance is that it doesn’t just sit on the steel; it fuses with it, creating a powerful chemical bond. This direct-to-metal adhesion creates a remarkably effective barrier against corrosion.

Primary Applications for FBE Coatings

A common question we receive is where FBE fits in a world of multi-layer coatings. The answer is that it serves several distinct and vital functions.

1. Standalone External Anti-Corrosion

This is the most traditional application for FBE. As a single-layer system, it provides excellent protection for buried pipelines in standard soil conditions. The key consideration here is the installation environment. For projects without a significant risk of severe mechanical damage during transport or backfilling, FBE provides exceptional and cost-effective corrosion protection. It remains a widely specified standard, particularly in North America, for oil and gas pipelines.

2. Internal Pipe Lining for Flow Efficiency

For our clients in the natural gas sector, this is one of the most valuable applications of FBE. A smooth, internally coated pipe has a significantly lower friction factor than uncoated steel. This “flow efficiency” lining:

- Reduces energy costs: It lowers the energy required to push gas through the pipeline, resulting in substantial operational savings at compressor stations over the asset’s lifetime.

- Protects from mild corrosives: It provides a clean, stable barrier that protects the steel from mildly corrosive elements or moisture within the product stream.

In this context, the primary benefit is often operational efficiency, offering a clear and measurable return on investment.

3. Rebar and Steel Reinforcement Coating

The versatility of FBE extends beyond pipelines. It is a leading solution for protecting steel reinforcing bars (rebar) used in concrete construction. Coated rebar is essential for infrastructure projects like bridges, parking structures, and marine facilities, where exposure to chlorides (from road salt or seawater) can cause premature corrosion and structural failure. FBE acts as a barrier, dramatically extending the life of the concrete structure.

4. The Foundation of 3LPE and 3LPP Systems

It is critical to recognize that even when you specify an advanced three-layer system like 3LPE or 3LPP, you are fundamentally relying on the proven anti-corrosion power of FBE. The first layer in any “3L” system is FBE. Its incredible adhesion to steel is what makes the entire multi-layer system possible. This is a testament to the coating’s foundational performance and reliability.

The Allland Steel Perspective

FBE is a high-performance coating that is much more than just a “single layer.” It is a versatile and essential tool in our anti-corrosion portfolio. The decision to use FBE as a standalone system or as the foundational layer in a multi-layer coating depends on a careful analysis of your project’s operational temperatures, installation environment, and long-term performance goals.

The specialists at Allland Steel have the expertise to help you navigate these choices and engineer the most effective and efficient coating solution for your application.

To learn more about our coating capabilities, please Contact a Specialist at Allland Steel.