Q:What is the main difference between LSAW and SSAW steel pipes?

One of the most frequent and important questions our clients, from procurement managers to project engineers, ask is: “What is the real difference between LSAW and SSAW pipe?” While both are types of Submerged Arc Welded (SAW) pipes, their manufacturing methods are fundamentally different, leading to distinct performance characteristics and ideal applications.

As specialists in welded pipe, we believe an informed choice is a smart choice. Our goal is to provide a clear, practical comparison to help you determine which pipe is the optimal solution for your project’s specific needs.

The Core Distinction: How They Are Made

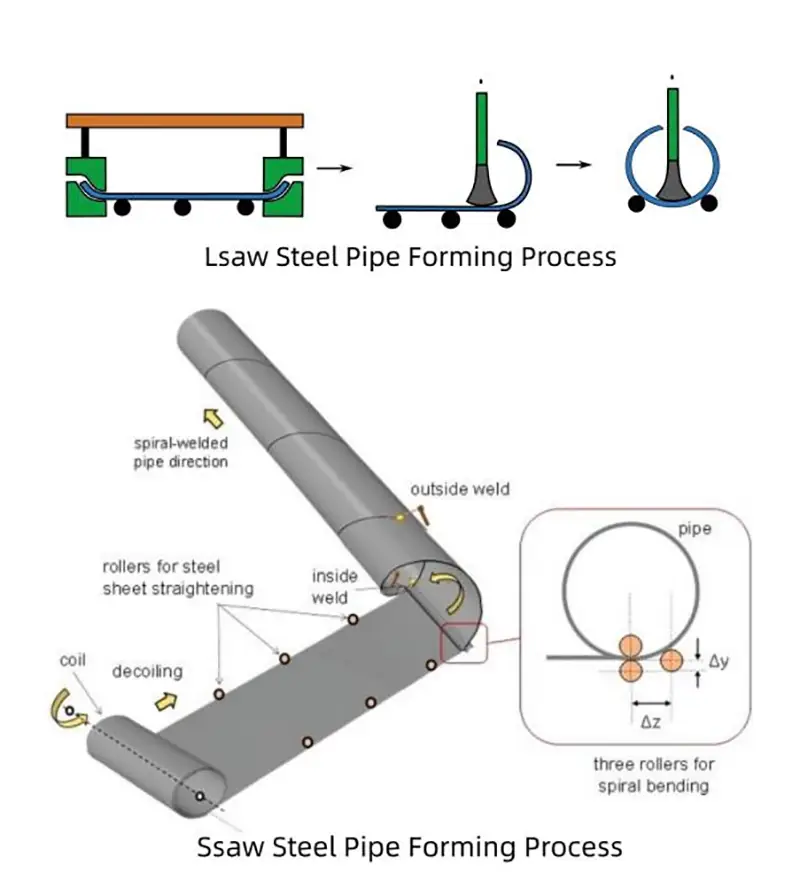

The primary difference between LSAW and SSAW pipe lies in their forming process and raw material format. This initial distinction dictates almost all other characteristics.

- LSAW (Longitudinal SAW) Pipe: Is manufactured from a single, discrete steel plate. The plate is formed into a cylinder, and the seam is welded straight along the length of the pipe. Think of it like rolling a rectangular sheet of paper into a tube and taping the straight edge.

- SSAW (Spiral SAW) Pipe: Is manufactured from a continuous steel coil. The coil is unwound and formed into a cylinder in a spiral or helical fashion, much like the cardboard tube in a roll of paper towels. The weld seam spirals around the pipe.

This fundamental difference in manufacturing is the key to understanding their respective strengths and weaknesses.

Head-to-Head Comparison: Performance and Application

Let’s break down how these manufacturing differences translate into real-world performance.

1. Weld Seam Characteristics

The weld seam is a critical structural component of the pipe.

- LSAW: Features a short, straight weld seam. From a risk management perspective, this presents a simpler and more reliable inspection profile for NDT. The residual stress from the welding process is also lower and more localized.

- SSAW: Has a long, helical weld that can be longer than the pipe itself. This can be a point of higher stress concentration, and the complex geometry can make comprehensive NDT inspection more challenging.

2. Dimensional Accuracy

In pipeline construction, precise dimensions are essential for efficient installation.

- LSAW: The JCOE process, particularly the mechanical expansion stage, gives LSAW pipes superior dimensional tolerance, including excellent roundness and straightness.

- SSAW: The spiral forming process, which relies on a continuous coil, can sometimes result in less precise dimensional control compared to the discrete plate method of LSAW.

3. Production Range and Cost-Effectiveness

The choice often involves a trade-off between the high-efficiency production of SSAW and the high-specification capability of LSAW.

- LSAW: Excels at producing pipes with very large diameters and, most notably, heavy wall thicknesses. The process is more meticulous and generally has a higher cost per ton.

- SSAW: Is a highly efficient process, capable of producing a very wide range of diameters from a single width of steel coil. This often makes it a more cost-effective choice for applications where its performance is sufficient.

4. Mechanical Performance

- LSAW: The use of single steel plates ensures high uniformity and consistency in the base material. This, combined with the verified integrity of its straight weld, makes LSAW the gold standard for high-pressure, mission-critical applications.

- SSAW: The helical weld can effectively distribute line stress. However, for critical high-pressure service, the longer weld seam and potential for variations within a steel coil are key considerations that must be carefully evaluated by project engineers.

Summary Table: LSAW vs. SSAW at a Glance

| Attribute | LSAW (Longitudinal) | SSAW (Spiral/Helical) |

| Raw Material | Single Steel Plate | Steel Coil |

| Weld Seam | Straight, short, parallel to pipe axis | Spiral, long, helical around pipe axis |

| Dimensional Accuracy | Excellent | Good to Standard |

| Wall Thickness | Ideal for heavy and extra-heavy walls | Standard to medium walls |

| Typical Application | High-pressure oil & gas, offshore, sour service | Low/medium-pressure water, structural, piling |

| Key Advantage | High integrity, heavy-wall capability | Cost-effectiveness, wide diameter range |

The Allland Steel Recommendation: Choosing the Right Pipe

There is no single “best” pipe—only the most appropriate pipe for a specific application. Our guidance is straightforward:

- For mission-critical applications involving high pressure, heavy walls, sour service, offshore placement, or where long-term integrity is the absolute priority, LSAW pipe is the superior and necessary choice.

- For general applications such as low-to-medium pressure water transmission, structural piling, or where cost-effectiveness for large diameters is a primary driver, SSAW pipe is often an excellent and suitable solution.

The team at Allland Steel is here to help you navigate these choices. We encourage you to contact us to discuss your project’s specific technical and commercial requirements to ensure you get the optimal piping solution.

Explore our LSAW Pipe and SSAW Pipe product pages for detailed specifications.

Or Contact a Specialist at Allland Steel for a personalized consultation.