Q:What is the JCOE process for LSAW pipes?

In high-stakes industries like oil & gas or offshore construction, where project specifications are demanding and failure is not an option, the choice of line pipe is a critical engineering decision. From our extensive experience, LSAW (Longitudinal Submerged Arc Welded) pipe is the premier choice for these applications. Its superior performance, however, is not a given—it is forged through a precise and advanced production method: the JCOE process.

To truly appreciate the quality of a premium LSAW pipe, it’s essential to understand the engineering that goes into it. This article will provide a clear, expert overview of the JCOE process, explaining how each meticulous step contributes to the final product’s integrity and reliability.

What is the JCOE Process?

The name JCOE is a mnemonic for the core mechanical steps that transform a flat steel plate into a high-performance pipe: J-ing, C-ing, O-ing, and Expanding.

At its core, the JCOE process is a highly controlled method of progressive forming. Unlike other methods that might introduce unpredictable stresses, this process is designed for precision and stability. The key takeaway for our clients is that this method produces a pipe with exceptional dimensional accuracy and uniform material properties from start to finish.

The JCOE Process in Detail: An Engineering Walkthrough

Every LSAW pipe we produce follows a rigorously controlled manufacturing journey. A critical factor that is often overlooked is how these initial steps directly impact the final quality.

Step 1: Plate Edge Milling & Pre-Bending

A flawless weld begins with a perfect edge. This is a non-negotiable first step where we utilize high-precision milling machines to prepare the long edges of the steel plate. This ensures the edges are perfectly parallel and profiled, which is a prerequisite for a sound weld. Following this, the edges are pre-bent. From an engineering perspective, this prevents the formation of sharp “peaks” at the seam during final forming, ensuring a smooth, uniform curvature across the pipe’s entire circumference.

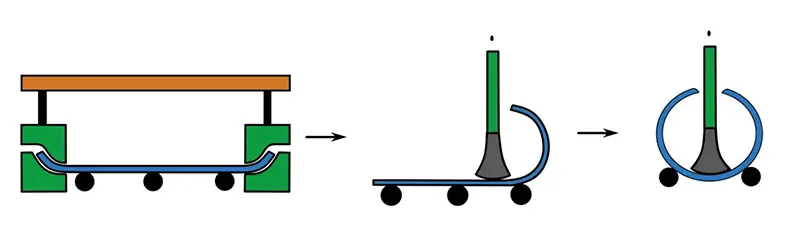

Step 2: J-C-O Forming

This is the heart of the shaping process, where raw geometry is turned into a cylindrical form. The plate moves through a sequence of powerful hydraulic presses:

- J-ing Press: One side of the plate is pressed into a “J” shape.

- C-ing Press: The opposite side is then formed, creating a “C” shape.

- O-ing Press: The pipe is closed into its final “O” shape within a set of dies, ensuring a tight and uniform seam gap for welding.

Step 3: Tack Welding & Internal/External Welding

Our commitment to weld integrity is absolute. The formed pipe is first tack-welded to secure its geometry. Then, the primary welding is performed using the Submerged Arc Welding (SAW) process, renowned for its stability and quality. We perform this both internally and externally to guarantee a full-penetration weld with exceptional strength and uniformity.

Step 4: Mechanical Expanding (The “E” Step)

This is arguably the most critical stage that sets JCOE-manufactured pipes apart. The welded pipe is fitted with an internal expander head. This head applies immense, uniform pressure from the inside out, slightly expanding the pipe’s diameter. The benefits of this step are significant:

- Stress Relief: It effectively neutralizes the internal stresses that accumulate during the forming and welding stages.

- Dimensional Perfection: It guarantees a superior level of roundness and straightness, which is critical for efficient on-site welding and installation.

- Property Enhancement: The process results in a pipe that is not only strong but also incredibly stable and reliable under pressure.

Step 5: Hydrostatic Testing & Non-Destructive Testing (NDT)

Verification is not just a final step; it’s an ongoing philosophy. Every single pipe is subjected to a hydrostatic test, pressurizing it well beyond its operational limits to confirm its strength. The entire weld seam also undergoes 100% NDT inspection, typically using Ultrasonic and X-ray methods, to detect any imperfections invisible to the human eye.

Step 6: Pipe End Beveling & Final Inspection

Finally, the pipe ends are beveled to exact specifications. This ensures that when the pipe arrives at the construction site, it is ready for seamless integration and efficient welding, saving valuable project time. A final visual and dimensional check confirms that the product meets every aspect of the required standard.

How the JCOE Process Fundamentally Guarantees Superior LSAW Pipe Quality

So, what does this highly controlled process mean for your project? The advantages are clear and direct:

- ✅ Predictable, High-Precision Dimensions: For engineers and installers, this means faster fit-up, less on-site fabrication, and more reliable welds.

- ✅ Enhanced Mechanical Reliability: The stress-relieved and dimensionally stable pipe provides a higher margin of safety and a longer service life, especially under cyclic or high-pressure loads.

- ✅ Flawless Weld Integrity: With a 100% inspected, double-sided SAW weld, you can have absolute confidence in the pipeline’s core strength.

- ✅ Capability for Demanding Specifications: The JCOE process is the definitive method for producing the heavy-wall, large-diameter, high-grade pipes required for the world’s most challenging energy and infrastructure projects.

Choose Allland steel, Choose Confidence

We believe an informed client is our best partner. Understanding the intricacies of the JCOE process helps you appreciate the value and reliability built into every LSAW pipe we deliver.

If you have further technical questions or wish to discuss how our manufacturing capabilities can meet the specific demands of your project, our team of specialists is ready to assist.

Learn more about our LSAW Pipe Products.

Or Contact Us Directly for a professional consultation and quote.