FAQ

Application & Selection

Explore key criteria for selecting steel pipes: application type, specifications, coatings and project demands to ensure optimal performance.

The long-term stability of any major bridge, port facility, or high-rise building rests entirely on the strength and integrity of its foundation. In modern construction, steel pipe piles are a proven, high-capacity solution for these deep foundations, but a frequent and critical question we address is which type of pipe is best suited for the job.

From an engineering standpoint, making the right choice is key to ensuring a foundation that is both safe and cost-effective. This guide will walk you through the primary options and the factors you should consider.

The Governing Standard for Piling: ASTM A252

Before discussing specific pipe types, it’s essential to establish the governing standard. For piling applications in North America and many international projects, that standard is overwhelmingly ASTM A252.

As we’ve covered previously, this specification is written exclusively for steel pipe intended for use as a structural, load-bearing element. Any pipe selected for a piling project, whether LSAW or SSAW, should be specified to meet or exceed the requirements of ASTM A252, typically Grade 2 (35 ksi yield) or Grade 3 (45 ksi yield).

Evaluating the Primary Options: SSAW vs. LSAW

Both SSAW (Spiral Weld) and LSAW (Longitudinal Weld) pipes are widely and successfully used for piling. The best choice depends on your project’s specific geotechnical conditions, structural loads, and budget.

SSAW (Spiral SAW) Pipe Piles: The Industry Workhorse

For a significant number of piling projects, SSAW pipe is the preferred choice, and for good reason.

- Key Advantage – Cost-Effectiveness: The continuous, efficient manufacturing process of SSAW pipe often makes it the most economical option, particularly for projects requiring large quantities of piling.

- Performance: SSAW pipe provides excellent structural capacity and is perfectly suited for most foundation designs where the pipe is driven to a specific depth and often filled with concrete. The spiral nature of its weld can also contribute to the pipe’s overall rigidity.

- Ideal Use Cases: SSAW pipe piles are an outstanding solution for a wide range of applications, including building and warehouse foundations, trestle bridges, retaining walls, and communication towers.

LSAW (Longitudinal SAW) Pipe Piles: The Heavy-Duty Solution

When project demands become more extreme, LSAW pipe piles offer an additional level of performance and security.

- Key Advantage – Heavy-Wall Capability: The JCOE manufacturing process allows LSAW pipes to be produced with extremely heavy wall thicknesses. This makes them exceptionally resistant to damage and buckling during driving in very hard or obstructed ground conditions.

- Performance: The use of single, high-quality steel plates ensures very uniform mechanical properties throughout the pipe, which is a benefit in designs with high, concentrated loads.

- Ideal Use Cases: LSAW pipe piles are the necessary choice for the most demanding projects, such as foundations for major long-span bridges, deepwater marine terminals, and offshore wind turbine jackets where piles are subjected to extreme axial, lateral, and dynamic loads.

Key Selection Factors for Your Project

Our technical specialists typically advise clients to consider these three factors:

- Geotechnical Conditions: Are you driving into soft clays or dense glacial till with boulders? Harsher driving conditions favor the robustness of a heavy-wall LSAW pipe.

- Structural Loads: What are the final design loads the foundation must support? Exceptionally high compressive or lateral loads may necessitate the heavy-wall capabilities of LSAW.

- Project Economics: Is this a standard foundation design in moderate soil conditions? If so, the high performance and cost-effectiveness of SSAW pipe make it a very compelling choice.

The Allland Steel Recommendation

Our guidance is to view SSAW pipe piles as the highly capable and economical baseline for the majority of foundation projects. For projects involving exceptional design loads, heavy-wall requirements, or particularly challenging driving conditions, upgrading to LSAW pipe piles provides a superior margin of safety and performance.

The optimal foundation solution depends on a thorough analysis of your project’s geotechnical report and structural design. The specialists at Allland Steel are experienced in supplying both LSAW and SSAW pipe piles for major infrastructure projects worldwide and can help you make the most effective material choice.

Contact a piling specialist at Allland Steel to review your project’s foundation requirements.

Planning a long-distance natural gas pipeline is one of the most complex undertakings in modern infrastructure. From our perspective as a key material supplier, we understand that while a project involves route planning, environmental assessments, and regulatory approvals, the integrity of the pipeline itself is the core of the entire system.

This guide outlines the critical technical considerations for pipe selection that are fundamental to ensuring a safe, reliable, and efficient natural gas transmission network for decades to come.

The Four Pillars of Pipeline Specification

Successfully specifying a pipe for natural gas transmission rests on four key pillars. Getting these right at the planning stage is essential for the project’s success.

Pillar 1: Standard and Specification Level (The Foundation of Safety)

This is the non-negotiable starting point for any gas pipeline.

- The Standard: The mandatory international standard for this application is API 5L.

- The Specification Level: For the vast majority of natural gas transmission lines, PSL2 (Product Specification Level 2) is the required choice.

Our expert guidance: While API 5L PSL1 is a valid standard for less critical applications, the high-pressure nature and significant public safety implications of gas transmission make the superior requirements of PSL2 essential. The mandatory fracture toughness, tighter chemical controls, and stricter testing protocols of PSL2 are fundamental to preventing failures and ensuring the pipeline’s integrity.

Pillar 2: Material Grade Selection (Balancing Strength and Economics)

The grade of steel determines its strength. Common grades for this application include API 5L X52, X65, and X70.

- The Principle: A higher-grade steel (like X70) has a higher yield strength than a lower-grade steel (like X52). This means a pipe with a thinner wall can safely contain the same amount of pressure.

- The Advantage: For long-distance pipelines, using a higher grade often leads to a lower total installed cost. While the cost per ton of the steel may be higher, the reduced wall thickness results in significant savings from:

- Lower overall steel tonnage required.

- Reduced transportation and handling costs.

- Faster welding times and lower consumable costs on site.

The selection of steel grade is a critical economic and engineering decision that should be made early in the design phase.

Pillar 3: Pipe Type and Manufacturing (Ensuring Reliability)

For large-diameter natural gas mainlines, the manufacturing process is key to ensuring reliability.

- The Choice: High-quality LSAW (Longitudinal SAW) pipe is a preferred choice for this application. High-Frequency Welded (HFW) and Seamless pipes are also used, typically for smaller diameter lines.

- The Reason: As we’ve detailed previously, the LSAW manufacturing process is ideally suited for producing the heavy-wall, high-grade, and dimensionally precise pipe required for these critical projects. The straight weld seam is also easily and reliably inspected with advanced NDT methods.

Pillar 4: External Coating System (Guaranteeing Longevity)

A natural gas pipeline is designed to be a 50+ year asset. Its primary long-term threat is external corrosion from the soil.

- The System: The industry benchmark for high-performance protection is a three-layer coating system, such as 3LPE (Three-Layer Polyethylene) or 3LPP (Three-Layer Polypropylene).

- The Rationale: This system provides a dual defense: the inner FBE layer offers excellent anti-corrosion and adhesion, while the rugged outer polyolefin layer provides robust mechanical protection against damage during installation. Investing in a premium coating system is a critical decision to protect the pipeline for its entire design life.

The Allland Steel Partnership: From Specification to Supply

Successfully planning and executing a natural gas pipeline requires deep expertise at every stage. At Allland Steel, we provide the high-specification API 5L PSL2 LSAW pipe that forms the backbone of these critical infrastructure projects.

Our technical specialists understand these four pillars intimately and are ready to work with your engineering team. We can help ensure your material specifications are optimized for safety, performance, and long-term value.

To discuss the requirements for your natural gas pipeline project, contact a technical specialist at Allland Steel.

When specifying pipelines for potable (drinking) water, the selection criteria extend far beyond simple corrosion protection. The primary responsibility is to ensure public health by preserving the quality and safety of the water being transported.

A critical question we address for municipal engineers and water authorities is which coating and lining systems are both certified as safe for drinking water and durable enough to guarantee a long service life. From our perspective, this is a matter of both uncompromising compliance and proven performance.

The Non-Negotiable Requirement: Certification to NSF/ANSI/CAN 61

Before we discuss specific coating types, the single most important requirement must be addressed: safety certification.

Any material, coating, or lining that will come into contact with drinking water must be certified to NSF/ANSI/CAN 61: “Drinking Water System Components – Health Effects.” This is the internationally recognized standard that ensures a product will not leach harmful levels of contaminants, metals, or chemicals into the water.

Our expert guidance: Always demand proof of this certification for any internal lining you are considering. This is a non-negotiable benchmark for ensuring public safety and meeting regulatory requirements.

Recommended Lining and Coating Systems

Once the NSF/ANSI/CAN 61 certification is confirmed, you can choose from several excellent, high-performance systems for the pipe’s interior and exterior.

Internal Linings (Water-Contact Surfaces)

1. Cement Mortar Lining This has been the waterworks industry’s trusted solution for decades, and for good reason. A layer of cement mortar is centrifugally applied to the pipe’s interior, creating a dense, smooth surface.

- Advantages: It creates a stable, inert barrier that not only prevents the steel from corroding but also actively passivates the steel surface. It is exceptionally durable, long-lasting, and highly cost-effective, especially for large-diameter water transmission mains.

2. Liquid-Applied Epoxy Linings These systems consist of a two-part, 100% solids (solvent-free) epoxy that is spray-applied to the pipe’s interior.

- Advantages: Liquid epoxies create an extremely smooth, glossy surface that can improve the pipe’s hydraulic efficiency (known as the Hazen-Williams “C” factor), potentially reducing long-term pumping costs.

- Critical Factor: It is essential that the specific epoxy formulation is certified to NSF/ANSI/CAN 61 and is applied under strict quality controls to ensure correct thickness and a full cure.

3. Fusion Bonded Epoxy (FBE) Linings This is a factory-applied, thermosetting powder coating. As with liquid epoxies, the specific FBE powder used must be certified for potable water contact.

- Advantages: FBE provides a very tough, damage-resistant, and consistent internal lining. The factory-controlled application process ensures a high degree of quality control and a reliable finish. It’s a premium choice for combining water safety with a robust, durable surface.

External Coatings (Protection from the Environment)

While the internal lining protects the water, the external coating protects the pipe from soil corrosion, moisture, and other environmental factors. Since these coatings do not contact the drinking water, they do not require NSF certification. Excellent, high-performance choices include:

- 3LPE / 3LPP Systems

- Fusion Bonded Epoxy (FBE)

- Polyurethane Coatings

The choice of external coating depends on the soil conditions, installation method, and operational environment.

The Allland Steel Commitment to Water Safety

Protecting our water resources is a shared responsibility. At Allland Steel, we provide pipeline solutions that meet the stringent safety and performance standards required for modern water infrastructure. We can supply pipes with a range of NSF/ANSI/CAN 61 certified internal linings and highly durable external coating systems.

Our specialists are ready to help you analyze your project’s requirements to engineer the optimal and safest pipeline solution.

Contact an Allland Steel specialist to discuss your potable water pipeline project.

Commercial & Logistics

Explore Allland’s commercial logistics FAQ: packaging, transport, storage and global shipping solutions for large‑diameter steel pipes.

At Allland Steel, we are committed to providing you with a timely, accurate, and competitive quotation for your project needs. To ensure our sales team can respond with the greatest efficiency and precision, it’s essential that you provide us with a complete set of technical and logistical specifications.

Think of this as a checklist for success. Providing the following information in your initial inquiry will allow us to bypass preliminary questions and move directly to preparing a comprehensive proposal for you.

Your Quotation Checklist: The 7 Key Pieces of Information

Please include the following details in your email or inquiry form. The more complete the information, the faster and more accurate your quote will be.

1. The Standard

This is the technical foundation of your request. Please specify the international standard the pipe must conform to.

- Example: API 5L, ASTM A252, ASTM A53

2. Material Grade

Within the standard, the specific grade determines the pipe’s mechanical properties, such as its strength.

- Example: Grade B, X60 PSL2, Grade 3

3. Full Dimensions

We need three key measurements to understand the physical product you require.

- Example: Outer Diameter (OD) 610mm, Wall Thickness (WT) 12.7mm, Length 12m

4. Total Quantity

Please provide the total quantity needed. This allows us to calculate production time and provide the best possible pricing.

- Example: 5,000 tons, or 1,200 pieces

5. Pipe Ends and Coating Requirements

These details ensure the pipe arrives ready for your specific application.

- Pipe Ends: Typically “Beveled Ends” for welding, or “Plain Ends”.

- Coating: Specify the required internal and/or external coating. For example, “External 3LPE coating” or “Internal FBE lining”.

6. Destination Port

To provide you with a CFR (Cost and Freight) or CIF (Cost, Insurance, and Freight) price, we need to know your nearest major seaport.

- Example: Port of Jebel Ali, UAE; Port of Rotterdam, Netherlands

7. Any Additional Requirements

Include any other special requirements for your project.

- Example: “Requires EN 10204 3.2 certification,” or “Special packaging with waterproof wrapping is needed.”

Why This Information Matters

From our experience, having this complete set of information is the key to a smooth and professional procurement process. It allows our technical team to confirm our manufacturing capabilities immediately and enables our commercial team to calculate the most accurate costs for materials, production, and logistics.

Our goal is to be more than just a supplier; we aim to be your most efficient and reliable partner. We look forward to receiving your detailed inquiry.

Ready to submit your inquiry? Click here to go to our Request for Quote page.

This is an excellent and practical question. We understand that every project, from large-scale infrastructure to specialized industrial applications, has a unique scope and material requirement.

At Allland Steel, our goal is to be a flexible and accessible partner. While we are fully equipped for large-tonnage orders, we also recognize the need for smaller or more specialized quantities.

Our General MOQ Guidelines

As a general guideline, our Minimum Order Quantity (MOQ) is typically determined on a per-specification basis. For most standard production runs, our MOQ is:

- 20 to 25 tons per single specification.

A “single specification” refers to a specific combination of outer diameter, wall thickness, and steel grade (e.g., 610mm OD x 12.7mm WT, API 5L X70 PSL2).

Why We Have an MOQ

From a manufacturing perspective, an MOQ is necessary to ensure an efficient production run. Setting up our mill for a specific size and grade of pipe is a complex process. An MOQ allows us to optimize this setup, manage raw material procurement effectively, and in turn, offer you the most competitive pricing for that item.

We Are Flexible: Discuss Your Project With Us

While the 20-ton guideline is our standard, we firmly believe in finding solutions for our clients. We recognize that certain situations require a different approach.

We encourage you to contact us even if your requirement is below our standard MOQ, especially for:

- Trial Orders: If you are a new partner or are testing a new product application.

- Specialized or High-Value Projects: Where the required quantity is naturally smaller due to the specific nature of the project.

- Ongoing Supply Agreements: Where smaller, regular deliveries are part of a larger, long-term supply plan.

In these cases, our sales and production teams will work together to review your requirement and explore all feasible options. It may be possible to combine your order with an existing production run or to develop a custom solution.

The Allland Steel Approach

Our primary objective is to build long-term partnerships. Don’t let a quantity requirement prevent you from starting a conversation with us. We are always open to discussing your project’s unique needs and are committed to finding a way to support you.

Contact our sales team to discuss your specific quantity requirements. We are ready to help.

This is a critical question for any international buyer. We understand that a steel pipe’s journey from our mill to your project site can be long and arduous. From our perspective, our responsibility for quality does not end when the pipe leaves our factory; it ends when it arrives at your destination in perfect condition.

To ensure this, Allland Steel has developed a robust, multi-layer packaging and handling protocol designed to protect your investment from both mechanical damage and environmental corrosion throughout the entire logistics process.

Our Standard Packaging and Protection Protocol

Unless specific custom requirements are requested, all our pipes for export are prepared using the following protective measures.

1. End Protection: Safeguarding the Most Critical Part

The beveled ends of a pipe are essential for efficient welding, and protecting them is our first priority.

- What we do: We fit durable plastic or steel end caps onto every pipe.

- Why it matters: This simple step provides highly effective protection against impacts during handling and loading, ensuring the pipe ends are not dented or deformed and arrive ready for immediate fit-up and welding.

2. Secure Bundling: For Safety and Handling Efficiency

For smaller to medium-diameter pipes, secure bundling is essential.

- What we do: Pipes are grouped into hexagonal bundles using high-strength, flat steel straps.

- Why it matters: This not only makes the cargo stable and secure within the shipping container or vessel hold but also significantly improves the efficiency and safety of loading and unloading operations at both ends of the journey.

3. Safe Lifting Practices: Preventing Surface Damage

The integrity of the pipe body and its coating is paramount.

- What we do: During all lifting operations at our facility, we exclusively use wide, fabric/nylon lifting slings. We strictly prohibit the use of wire ropes directly on the pipe body.

- Why it matters: Wire ropes can create “point loads” that can dent the pipe or, more critically, damage the anti-corrosion coating. Soft slings distribute the lifting force evenly, preserving the integrity of both the steel and its protective layers.

4. Additional Protection for Coated Pipes

Coated pipes (such as 3LPE) require an extra layer of care to protect them from UV degradation and surface abrasion.

- What we do: For clients who require it, we can provide additional protective wrapping, such as waterproof tarpaulins or tightly wrapped plastic sheeting.

- Why it matters: This provides an effective barrier against rain, sea spray, and dirt, and offers an extra layer of defense against scratches and scuffs during transit.

The Allland Steel Commitment to Delivery Excellence

Our logistics team works closely with trusted shipping lines to ensure your cargo is stowed securely and handled professionally. We believe that professional packaging is a clear indicator of a manufacturer’s overall commitment to quality. When you receive a shipment from Allland Steel, the care we take with our packaging is the first thing you will see—a clear sign of the quality that lies within.

If your project has unique or challenging logistical requirements, we invite you to contact our logistics team to engineer a custom packaging and shipping solution.

Product & Manufacturing

Explore product & manufacturing FAQ: key topics like pipe diameters, grades, JCOE forming, LSAW/SSAW technologies and coating options.

One of the most frequent and important questions our clients, from procurement managers to project engineers, ask is: “What is the real difference between LSAW and SSAW pipe?” While both are types of Submerged Arc Welded (SAW) pipes, their manufacturing methods are fundamentally different, leading to distinct performance characteristics and ideal applications.

As specialists in welded pipe, we believe an informed choice is a smart choice. Our goal is to provide a clear, practical comparison to help you determine which pipe is the optimal solution for your project’s specific needs.

The Core Distinction: How They Are Made

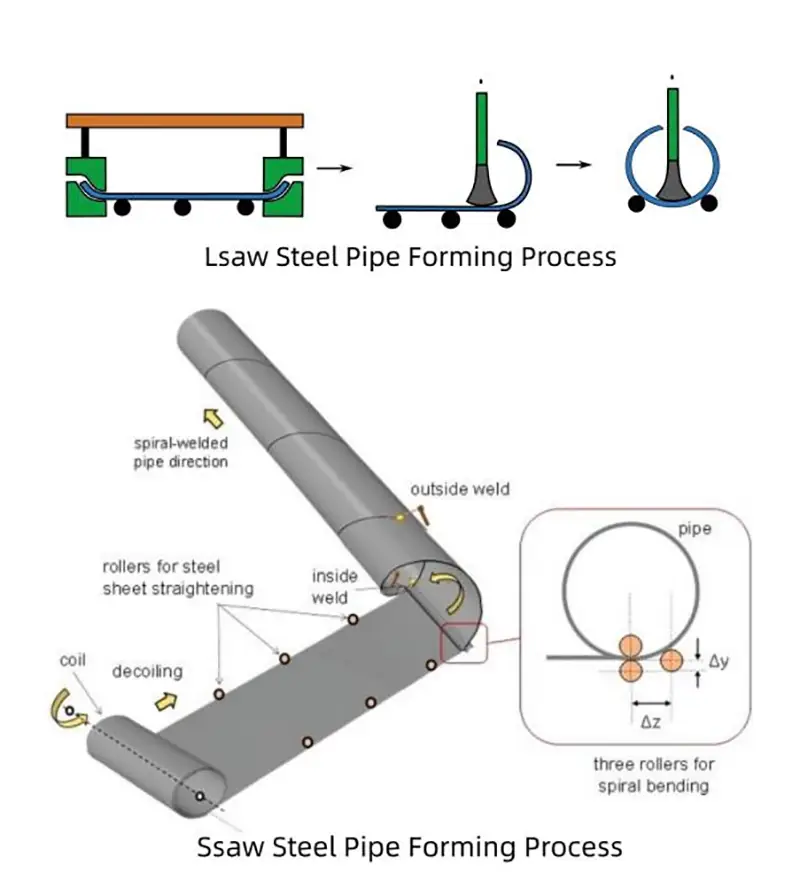

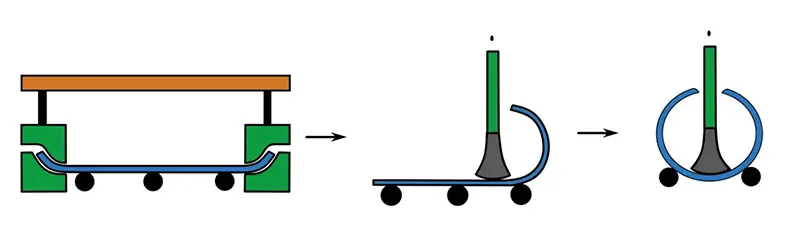

The primary difference between LSAW and SSAW pipe lies in their forming process and raw material format. This initial distinction dictates almost all other characteristics.

- LSAW (Longitudinal SAW) Pipe: Is manufactured from a single, discrete steel plate. The plate is formed into a cylinder, and the seam is welded straight along the length of the pipe. Think of it like rolling a rectangular sheet of paper into a tube and taping the straight edge.

- SSAW (Spiral SAW) Pipe: Is manufactured from a continuous steel coil. The coil is unwound and formed into a cylinder in a spiral or helical fashion, much like the cardboard tube in a roll of paper towels. The weld seam spirals around the pipe.

This fundamental difference in manufacturing is the key to understanding their respective strengths and weaknesses.

Head-to-Head Comparison: Performance and Application

Let’s break down how these manufacturing differences translate into real-world performance.

1. Weld Seam Characteristics

The weld seam is a critical structural component of the pipe.

- LSAW: Features a short, straight weld seam. From a risk management perspective, this presents a simpler and more reliable inspection profile for NDT. The residual stress from the welding process is also lower and more localized.

- SSAW: Has a long, helical weld that can be longer than the pipe itself. This can be a point of higher stress concentration, and the complex geometry can make comprehensive NDT inspection more challenging.

2. Dimensional Accuracy

In pipeline construction, precise dimensions are essential for efficient installation.

- LSAW: The JCOE process, particularly the mechanical expansion stage, gives LSAW pipes superior dimensional tolerance, including excellent roundness and straightness.

- SSAW: The spiral forming process, which relies on a continuous coil, can sometimes result in less precise dimensional control compared to the discrete plate method of LSAW.

3. Production Range and Cost-Effectiveness

The choice often involves a trade-off between the high-efficiency production of SSAW and the high-specification capability of LSAW.

- LSAW: Excels at producing pipes with very large diameters and, most notably, heavy wall thicknesses. The process is more meticulous and generally has a higher cost per ton.

- SSAW: Is a highly efficient process, capable of producing a very wide range of diameters from a single width of steel coil. This often makes it a more cost-effective choice for applications where its performance is sufficient.

4. Mechanical Performance

- LSAW: The use of single steel plates ensures high uniformity and consistency in the base material. This, combined with the verified integrity of its straight weld, makes LSAW the gold standard for high-pressure, mission-critical applications.

- SSAW: The helical weld can effectively distribute line stress. However, for critical high-pressure service, the longer weld seam and potential for variations within a steel coil are key considerations that must be carefully evaluated by project engineers.

Summary Table: LSAW vs. SSAW at a Glance

| Attribute | LSAW (Longitudinal) | SSAW (Spiral/Helical) |

| Raw Material | Single Steel Plate | Steel Coil |

| Weld Seam | Straight, short, parallel to pipe axis | Spiral, long, helical around pipe axis |

| Dimensional Accuracy | Excellent | Good to Standard |

| Wall Thickness | Ideal for heavy and extra-heavy walls | Standard to medium walls |

| Typical Application | High-pressure oil & gas, offshore, sour service | Low/medium-pressure water, structural, piling |

| Key Advantage | High integrity, heavy-wall capability | Cost-effectiveness, wide diameter range |

The Allland Steel Recommendation: Choosing the Right Pipe

There is no single “best” pipe—only the most appropriate pipe for a specific application. Our guidance is straightforward:

- For mission-critical applications involving high pressure, heavy walls, sour service, offshore placement, or where long-term integrity is the absolute priority, LSAW pipe is the superior and necessary choice.

- For general applications such as low-to-medium pressure water transmission, structural piling, or where cost-effectiveness for large diameters is a primary driver, SSAW pipe is often an excellent and suitable solution.

The team at Allland Steel is here to help you navigate these choices. We encourage you to contact us to discuss your project’s specific technical and commercial requirements to ensure you get the optimal piping solution.

Explore our LSAW Pipe and SSAW Pipe product pages for detailed specifications.

Or Contact a Specialist at Allland Steel for a personalized consultation.

In the world of industrial pipes, many options exist, and a common question our clients ask is why LSAW (Longitudinal Submerged Arc Welded) pipe is so often specified for the most critical projects. While other pipes like SSAW or ERW certainly have their place, when you enter the realm of high-pressure, high-stakes applications, the advantages of LSAW pipe are not just beneficial—they are irreplaceable.

Our goal here is to move beyond simple definitions and explain the core engineering and material science principles that make LSAW the definitive choice for projects where performance and safety are non-negotiable.

It Starts with the Foundation: Superior Raw Material and Forming

A critical factor that is often overlooked is that the final quality of a pipe is predetermined by its raw material and forming method. LSAW pipe production begins with a single, discrete hot-rolled steel plate.

From a materials science perspective, this is a significant advantage. A single plate has more consistent mechanical properties and a cleaner, more uniform internal structure compared to the steel coils used for other welded pipes. This inherent material integrity is the foundation upon which all other performance benefits are built.

Key Advantages of LSAW Pipes in Demanding Scenarios

Here are the specific, performance-driven advantages that make LSAW pipe the superior choice for high-end applications.

1. Unmatched Weld Integrity and Safety

The weld is the heart of any welded pipe. The LSAW pipe features a single, straight, and relatively short weld seam. In practice, this simple geometry provides two profound benefits:

- Minimalist Weld Seam: It presents the shortest possible weld path, statistically reducing the chance of any imperfections.

- Reliable Inspection: The straight seam is ideal for precise and highly reliable Non-Destructive Testing (NDT), such as ultrasonic and X-ray inspection. This allows us to guarantee a level of weld integrity that is difficult to achieve with the long, helical seam of an SSAW pipe.

2. Exceptional Dimensional Accuracy

For engineers and on-site crews, dimensional stability is crucial. Thanks to the JCOE forming process and particularly the mechanical expansion stage, LSAW pipes exhibit outstanding roundness, straightness, and uniform diameter. In a real-world scenario, this translates directly to:

- Faster project timelines due to easier fit-up and welding.

- Lower labor costs associated with rework and adjustments.

- Better flow dynamics within the finished pipeline.

3. Unrivaled Capability for Heavy-Wall and High-Grade Steel

When a project requires pushing the boundaries of pressure and depth, heavy-wall pipe is essential. The JCOE manufacturing process is uniquely capable of forming extremely thick steel plates into pipes—a feat that is technically and economically challenging for coil-based methods. This allows us to produce LSAW pipes with significant wall thickness, perfectly suited for deepwater, offshore, and high-pressure gas applications. Furthermore, this process is ideal for use with high-grade steels like X70, X80, and beyond, meeting the demands of modern energy transportation.

4. Superior Performance in Sour Service (H₂S Environments)

For our clients in the oil and gas sector, sour service performance is a primary concern. The clean steel from single plates and the stable, stress-relieved condition of LSAW pipe (thanks to mechanical expansion) give it superior resistance to Hydrogen-Induced Cracking (HIC) and Sulfide Stress Cracking (SSC). This is a critical safety and performance feature for transporting sour crude oil and natural gas.

The Allland Steel Verdict: The Right Pipe for the Mission

Our role as specialists is not just to sell pipes, but to help you match the right product to your project’s specific demands. While ERW pipes are excellent for low-pressure applications and SSAW pipes offer a cost-effective solution for large-diameter, low-pressure lines, the evidence is clear.

For mission-critical infrastructure where long-term safety, reliability, and performance are paramount, LSAW pipe is the only choice.

To explore the technical specifications of our products, please view our LSAW Pipe Product Page.

Or Contact a Specialist at Allland Steel to discuss the unique requirements of your project

In high-stakes industries like oil & gas or offshore construction, where project specifications are demanding and failure is not an option, the choice of line pipe is a critical engineering decision. From our extensive experience, LSAW (Longitudinal Submerged Arc Welded) pipe is the premier choice for these applications. Its superior performance, however, is not a given—it is forged through a precise and advanced production method: the JCOE process.

To truly appreciate the quality of a premium LSAW pipe, it’s essential to understand the engineering that goes into it. This article will provide a clear, expert overview of the JCOE process, explaining how each meticulous step contributes to the final product’s integrity and reliability.

What is the JCOE Process?

The name JCOE is a mnemonic for the core mechanical steps that transform a flat steel plate into a high-performance pipe: J-ing, C-ing, O-ing, and Expanding.

At its core, the JCOE process is a highly controlled method of progressive forming. Unlike other methods that might introduce unpredictable stresses, this process is designed for precision and stability. The key takeaway for our clients is that this method produces a pipe with exceptional dimensional accuracy and uniform material properties from start to finish.

The JCOE Process in Detail: An Engineering Walkthrough

Every LSAW pipe we produce follows a rigorously controlled manufacturing journey. A critical factor that is often overlooked is how these initial steps directly impact the final quality.

Step 1: Plate Edge Milling & Pre-Bending

A flawless weld begins with a perfect edge. This is a non-negotiable first step where we utilize high-precision milling machines to prepare the long edges of the steel plate. This ensures the edges are perfectly parallel and profiled, which is a prerequisite for a sound weld. Following this, the edges are pre-bent. From an engineering perspective, this prevents the formation of sharp “peaks” at the seam during final forming, ensuring a smooth, uniform curvature across the pipe’s entire circumference.

Step 2: J-C-O Forming

This is the heart of the shaping process, where raw geometry is turned into a cylindrical form. The plate moves through a sequence of powerful hydraulic presses:

- J-ing Press: One side of the plate is pressed into a “J” shape.

- C-ing Press: The opposite side is then formed, creating a “C” shape.

- O-ing Press: The pipe is closed into its final “O” shape within a set of dies, ensuring a tight and uniform seam gap for welding.

Step 3: Tack Welding & Internal/External Welding

Our commitment to weld integrity is absolute. The formed pipe is first tack-welded to secure its geometry. Then, the primary welding is performed using the Submerged Arc Welding (SAW) process, renowned for its stability and quality. We perform this both internally and externally to guarantee a full-penetration weld with exceptional strength and uniformity.

Step 4: Mechanical Expanding (The “E” Step)

This is arguably the most critical stage that sets JCOE-manufactured pipes apart. The welded pipe is fitted with an internal expander head. This head applies immense, uniform pressure from the inside out, slightly expanding the pipe’s diameter. The benefits of this step are significant:

- Stress Relief: It effectively neutralizes the internal stresses that accumulate during the forming and welding stages.

- Dimensional Perfection: It guarantees a superior level of roundness and straightness, which is critical for efficient on-site welding and installation.

- Property Enhancement: The process results in a pipe that is not only strong but also incredibly stable and reliable under pressure.

Step 5: Hydrostatic Testing & Non-Destructive Testing (NDT)

Verification is not just a final step; it’s an ongoing philosophy. Every single pipe is subjected to a hydrostatic test, pressurizing it well beyond its operational limits to confirm its strength. The entire weld seam also undergoes 100% NDT inspection, typically using Ultrasonic and X-ray methods, to detect any imperfections invisible to the human eye.

Step 6: Pipe End Beveling & Final Inspection

Finally, the pipe ends are beveled to exact specifications. This ensures that when the pipe arrives at the construction site, it is ready for seamless integration and efficient welding, saving valuable project time. A final visual and dimensional check confirms that the product meets every aspect of the required standard.

How the JCOE Process Fundamentally Guarantees Superior LSAW Pipe Quality

So, what does this highly controlled process mean for your project? The advantages are clear and direct:

- ✅ Predictable, High-Precision Dimensions: For engineers and installers, this means faster fit-up, less on-site fabrication, and more reliable welds.

- ✅ Enhanced Mechanical Reliability: The stress-relieved and dimensionally stable pipe provides a higher margin of safety and a longer service life, especially under cyclic or high-pressure loads.

- ✅ Flawless Weld Integrity: With a 100% inspected, double-sided SAW weld, you can have absolute confidence in the pipeline’s core strength.

- ✅ Capability for Demanding Specifications: The JCOE process is the definitive method for producing the heavy-wall, large-diameter, high-grade pipes required for the world’s most challenging energy and infrastructure projects.

Choose Allland steel, Choose Confidence

We believe an informed client is our best partner. Understanding the intricacies of the JCOE process helps you appreciate the value and reliability built into every LSAW pipe we deliver.

If you have further technical questions or wish to discuss how our manufacturing capabilities can meet the specific demands of your project, our team of specialists is ready to assist.

Learn more about our LSAW Pipe Products.

Or Contact Us Directly for a professional consultation and quote.

A frequent and essential question we receive from project planners and engineers relates to the specific manufacturing capabilities of our LSAW pipe mills. Understanding these parameters is key to aligning our production strengths with your project’s unique engineering and design requirements.

At Allland Steel, our significant investment in modern JCOE (J-ing, C-ing, O-ing, Expanding) manufacturing technology allows us to produce a comprehensive range of high-specification LSAW pipes. Below is a detailed outline of our standard production capabilities.

Core Production Capability Overview

It’s important to view this data as a general guide to our capabilities. We often have the flexibility to produce non-standard or custom dimensions to meet specific project demands.

| Parameter | Specification Range | Notes |

| Outer Diameter (OD) | 406.4 mm – 1524 mm (16″ – 60″) | Continuous range available. |

| Wall Thickness (WT) | 6.0 mm – 60.0 mm (1/4″ – 3″) | Heavy-wall capability is a key strength. |

| Length | 3.0 m – 12.5 m (10” – 40”) | Can be customized based on project needs. |

| Steel Standards | API、ISO、EN、ASTM、DIN、JIS、GB、CSA、GOST | Comprehensive international standard compliance. |

Beyond the Numbers: What Our Capabilities Mean for Your Project

While the figures provide a technical summary, the real value lies in what they enable you to achieve.

Large Diameter and Heavy Wall Thickness

Our ability to produce pipes with substantial diameters and heavy wall thicknesses is critical for projects where high pressure and significant external loads are primary design concerns. This makes our LSAW pipes the ideal solution for:

- High-pressure natural gas transmission mainlines.

- Deepwater and offshore pipelines.

- Large-scale structural components for bridges, stadiums, and offshore platforms.

High-Grade Steel (Up to X70)

From a project economics perspective, utilizing high-grade steel like API 5L X70 can lead to significant advantages. A higher-grade material allows for a reduced wall thickness while maintaining the same pressure rating. This results in:

- A lighter pipe, reducing material tonnage and cost.

- Lower transportation and handling expenses.

- Reduced welding time and material consumption on site.

A core principle at Allland Steel is that our quality control standards are absolute. Every pipe, regardless of its dimensions or steel grade, undergoes the same rigorous inspection and testing regimen, including hydrostatic testing and 100% NDT on the weld seam.

Discuss Your Project with Our Specialists

The specifications listed above represent our standard capabilities, but we often work with clients to develop solutions for unique and challenging projects. The best way to confirm our ability to meet your specific requirements is to connect with our team.

We are ready to review your technical specifications and provide a detailed manufacturing plan that aligns with your project’s goals and timeline.

For more detailed information, please review the technical data on our LSAW Pipe Product Page.

Or Contact a Specialist at Allland Steel to discuss your specific manufacturing needs.

Selecting the right anti-corrosion coating is one of the most critical decisions in ensuring a pipeline’s long-term integrity and service life. A common and important choice our clients face is between two premier coating systems: 3LPE and 3LPP.

While both are advanced, three-layer systems that offer exceptional protection, they are not interchangeable. They are engineered for different operational challenges. Our goal is to clarify these differences, enabling you to make the most reliable and cost-effective choice for your project.

Understanding the Shared “Three-Layer” Foundation

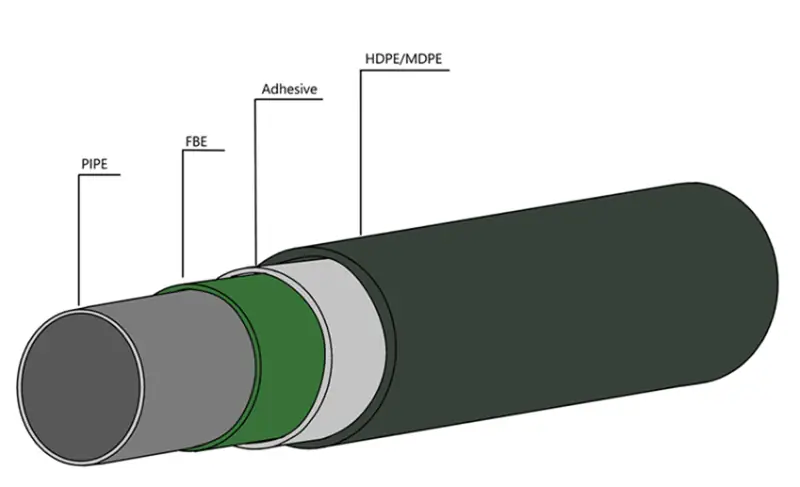

First, it’s important to understand what the “3L” signifies. Both 3LPE and 3LPP share the same fundamental, high-performance structure:

- Layer 1: Fusion Bonded Epoxy (FBE): This primer layer is applied directly to the blasted steel surface. Its primary role is to provide excellent adhesion and act as the main barrier against corrosion.

- Layer 2: Copolymer Adhesive: This functions as the “glue,” creating a strong, chemical bond between the epoxy layer and the final topcoat.

- Layer 3: Polyolefin Topcoat: This is the outer layer that provides robust mechanical protection.

The only difference between 3LPE and 3LPP lies in the material used for this crucial third layer: Polyethylene (PE) or Polypropylene (PP). This single difference, however, dramatically changes the coating’s performance profile.

Head-to-Head: 3LPE (Polyethylene) vs. 3LPP (Polypropylene)

Let’s compare the two systems based on the factors that matter most in project design and execution.

1. Operating Temperature Resistance: The Deciding Factor

From an engineering standpoint, the operational temperature of the pipeline is the single most important factor in this decision.

- 3LPE: Is the industry standard for pipelines operating at normal temperatures. It provides reliable performance for continuous service up to 80-85°C (176-185°F).

- 3LPP: Is specifically engineered for high-temperature applications. The polypropylene topcoat gives it a significantly higher temperature resistance, making it suitable for continuous service up to 110°C (230°F) and even higher for specialized formulations.

A key principle in pipeline design is that exceeding a coating’s temperature limit can lead to accelerated aging and premature failure.

2. Mechanical Properties: Hardness and Abrasion Resistance

The outer layer must protect the pipe from damage during transportation, installation, and throughout its service life.

- 3LPP: Polypropylene is an inherently harder and more rigid material than polyethylene. This gives 3LPP superior resistance to abrasion, impact, gouging, and penetration.

- 3LPE: Offers excellent mechanical protection for most standard conditions but is a slightly softer and more flexible material.

This makes 3LPP the preferred choice for challenging installation environments, such as rocky terrains, horizontal directional drilling (HDD), or areas with significant soil stress.

Summary Table: Key Differences at a Glance

| Property | 3LPE (Three-Layer Polyethylene) | 3LPP (Three-Layer Polypropylene) |

| Max. Operating Temp. | ~85°C (185°F) | >110°C (230°F) |

| Mechanical Resistance | Excellent | Superior (Harder, more abrasion resistant) |

| Flexibility | More Flexible | More Rigid |

| Typical Application | Standard onshore/offshore oil & gas, water | High-temp pipelines, harsh terrains (HDD) |

| Relative Cost | Standard | Higher |

The Allland Steel Recommendation: Which Coating Is Right for You?

Our guidance for choosing between these two excellent systems is clear and based on your project’s specific needs:

- Choose 3LPE if: Your pipeline’s continuous operating temperature will remain below 80°C, and the installation environment is not exceptionally harsh. For a vast majority of oil, gas, and water pipelines, 3LPE provides the optimal balance of high performance, reliability, and cost-effectiveness.

- Choose 3LPP if: Your pipeline will operate at elevated temperatures (above 80°C), will be installed in a challenging or rocky environment, or requires the absolute maximum in mechanical damage resistance. While 3LPP has a higher upfront cost, it is a value-driven investment for projects where its superior resistance prevents costly future repairs and ensures long-term asset integrity.

The selection of a coating system has lasting implications. The specialists at Allland Steel can help you analyze your project’s operational data to make the most reliable and effective choice.

To learn more about our coating capabilities, please Contact a Specialist at Allland Steel.

Quality & Services

Quality‑assurance and service FAQ: inspection, mill test certificates (MTCs), traceability, packaging and after‑sales support for steel pipes.

In today’s complex construction and energy projects, we understand that a “one-size-fits-all” approach is rarely the most efficient solution. A frequent question from our clients is what capabilities we offer beyond the supply of standard pipe.

At Allland Steel, we pride ourselves on being a solutions partner. We offer a comprehensive range of in-house, value-added services designed to save you time, reduce on-site work, and deliver a product that is much closer to your final installation requirements. Our goal is to help you streamline your project’s supply chain and improve its overall efficiency.

Our Value-Added Service Capabilities

Our services are designed to integrate seamlessly with our pipe manufacturing, ensuring a single source of quality control from start to finish.

1. Precision Cutting-to-Length

While we supply pipes in standard lengths, many projects require specific, non-standard dimensions.

- Our Service: We provide precision cutting services to deliver pipes to the exact lengths required by your engineering drawings.

- Your Advantage: This service is particularly valuable for piling and structural applications. It ensures that pipes arrive on site ready for immediate use, eliminating the need for time-consuming and costly on-site cutting. This significantly reduces material waste, improves site safety, and helps maintain tight construction schedules.

2. Pipe End Preparation

Properly prepared ends are critical for efficient and high-quality welding.

- Our Service: We offer factory-controlled end preparation, most commonly beveling for butt-welding applications. We can create precise, uniform bevels that meet project specifications.

- Your Advantage: A perfect, factory-quality bevel ensures a better fit-up for welding crews, which translates into faster welding times and a higher-quality, more reliable weld.

3. Custom Coatings and Linings

Our expertise extends beyond the standard anti-corrosion systems.

- Our Service: We work with clients to apply a wide range of specialized coatings and linings. This can include custom RAL colors for architecturally exposed steelwork, abrasion-resistant overlays (AROs) for trenchless pipeline installations (HDD), or specific internal linings for chemical or product resistance.

- Your Advantage: We can engineer a complete coating solution tailored to your project’s unique aesthetic or performance criteria, ensuring you don’t have to compromise with a standard off-the-shelf product.

4. Light Fabrication and Attachments

To further simplify your on-site work, we can perform light fabrication in our controlled workshop environment.

- Our Service: This includes the precision welding of components such as flanges, lifting lugs (essential for handling large-diameter piles), or other project-specific attachments.

- Your Advantage: Performing this work in our facility is typically safer, faster, and more cost-effective than doing so on a busy construction site. It allows us to deliver components that are closer to their final assembled state, simplifying your logistics and workflow.

The Allland Steel Advantage: A Single-Source Solution

From a project management perspective, integrating these services with your pipe supply offers a significant advantage. It streamlines the procurement process, reduces the number of vendors to manage, and places the responsibility for end-to-end quality squarely on a single, trusted partner. Our goal is to deliver a more complete solution, not just a product.

Discuss Your Custom Requirements

Every project has unique challenges. We invite you to bring yours to us.

The specialists at Allland Steel are committed to finding innovative and efficient solutions that enhance the value we bring to your project. Contact us today to discuss your specific fabrication and coating requirements.

The most fundamental question a client can ask is, “How do you guarantee quality?” At Allland Steel, we believe quality is not a feature to be inspected at the end of the line; it is a core principle that is built into every stage of our process, from raw material procurement to final shipment.

Our commitment is to deliver not just a product that meets a standard, but a product that inspires absolute confidence in the safety and longevity of your project. This is achieved through our comprehensive, multi-stage Quality Management System.

A Multi-Stage Quality Management System

Our quality philosophy is one of prevention, not just detection. We ensure excellence through a rigorous process that includes the following key stages.

1. Rigorous Raw Material Inspection

You cannot create a high-quality finished product from a substandard raw material. That’s why our quality process begins before production even starts.

- Supplier Verification: We source our steel plates and coils exclusively from reputable, pre-qualified mills.

- Certificate Validation: Every batch of incoming raw material is accompanied by a Mill Test Certificate (MTC), which we meticulously verify against the required standards.

- Independent Testing: We perform our own independent chemical analysis and mechanical tests on samples of the raw material to confirm that it meets the precise specifications for the project. This ensures the foundation of your pipe is flawless.

2. In-Process Monitoring and Control

During the manufacturing process, our quality teams monitor critical parameters in real-time to ensure consistency and compliance. This includes:

- Dimensional Control: Continuous checks on diameter, wall thickness, and roundness during the forming stages.

- Welding Parameter Monitoring: Real-time digital monitoring of key variables for our Submerged Arc Welding (SAW) process, such as amperage, voltage, and travel speed, to guarantee a consistent, high-integrity weld.

- Visual Inspection: Trained inspectors are stationed at every key transition point in the production line to identify any surface imperfections.

3. Comprehensive Final Inspection and Testing

This is the final verification stage, where every finished pipe is subjected to a battery of tests to prove its quality.

- Hydrostatic Testing: 100% of our pipes intended for pressure service undergo a hydrostatic test. The pipe is pressurized with water to a level significantly higher than its operational rating to guarantee its strength and leak-proof integrity.

- Non-Destructive Testing (NDT): 100% of the weld seam on every pipe is inspected using advanced NDT methods, such as Ultrasonic Testing (UT) and/or X-Ray Inspection, to detect any imperfections below the surface.

- Destructive Testing: Samples from each production batch are subjected to a series of destructive tests in our laboratory. These include tensile tests (to verify strength), bend tests (to verify ductility), and Charpy impact tests (to verify fracture toughness), providing definitive proof of the pipe’s mechanical properties.

4. Full Traceability and Documentation

We believe that transparency is the foundation of trust. Our quality system ensures full traceability for every product. Each pipe is marked with a unique identifier that allows it to be traced back to its specific production batch, the raw material it was made from, and all the associated test results. This information is compiled into a formal Type 3.1 Mill Test Certificate (MTC) in accordance with the EN 10204 standard, which is provided to you as a complete record of your product’s quality.

The Allland Steel Quality Guarantee

Our reputation is built on the trust our clients place in our products. This trust is earned daily through an unwavering commitment to quality at every level of our organization. When you partner with Allland Steel, you are partnering with a company dedicated to delivering performance, reliability, and peace of mind.

To learn more about our certifications and quality processes, contact a specialist at Allland Steel.

Absolutely. From our perspective, a steel pipe delivered without a complete and accurate Mill Test Certificate (MTC) is an incomplete product. We consider the MTC to be a fundamental component of our supply, as it provides you with the ultimate proof of quality and full traceability for your materials.

Providing a comprehensive MTC with every order is an essential and non-negotiable part of our quality assurance process.

What Information Is Included in Our MTC?

When you receive a shipment from Allland Steel, it will be accompanied by an MTC that provides a complete summary of the product’s tested properties. You can expect to find the following key information:

- Product Description: Including the standard (e.g., API 5L), grade (e.g., X70), product specification level (PSL), and full dimensions.

- Heat Number: A unique code that provides full traceability back to the specific batch of steel used to manufacture your pipe.

- Chemical Composition: A detailed analysis showing the precise percentage of key chemical elements in the steel.

- Mechanical Properties: The specific, measured results from destructive tests, including:

- Yield Strength

- Tensile Strength

- Elongation

- Additional Test Results: The outcomes of any other tests required by the standard, such as Charpy impact toughness values or hydrostatic test pressure and duration.

- Statement of Compliance: A formal declaration that the product has been manufactured and tested in full accordance with the requirements of the ordered standard.

Our Adherence to the EN 10204 Standard

To ensure our documentation is clear, consistent, and globally recognized, our MTCs are issued in accordance with the European standard EN 10204.

- As our standard practice, we provide a Type 3.1 MTC. This certificate is validated by our authorized quality control department, which operates independently of our production division, ensuring the integrity of the results.

- For projects with the most stringent quality assurance requirements, we can also facilitate a Type 3.2 MTC, which involves co-validation by an approved independent third-party inspection agency.

For a complete explanation of the different certificate types and their importance, we invite you to read our detailed guide on the topic.

Learn More: Understanding EN 10204: The Standard for Material Test Certificates

The Allland Steel Promise

The MTC is our documented promise of quality and transparency to you. When you partner with Allland Steel, you receive not only a superior product but also the complete and reliable documentation to prove it.

If you have any questions about interpreting your certificate or have specific documentation requirements for your project, our team is always here to help.

Standards & Specifications

Explore pipe standards & specifications FAQ: learn about API 5L, ASTM, EN and DIN rules for steel pipes to ensure correct quality, grade and manufacturing.

Within the critical API 5L standard for line pipe, one of the most important and frequently asked questions revolves around the distinction between PSL1 and PSL2. From our perspective as industry specialists, this is more than a technical detail; it’s a fundamental decision that directly impacts a pipeline’s safety, performance, and long-term integrity.

Our goal is to clarify this distinction, helping engineers, project managers, and procurement teams specify the correct product with absolute confidence.

What Does PSL Mean?

PSL stands for Product Specification Level. The American Petroleum Institute (API) created these two distinct levels to provide clear tiers of technical and quality requirements for line pipe used in the oil and gas industry.

- PSL1: Represents the standard quality level for line pipe.

- PSL2: Represents a higher quality level with significantly more stringent requirements for testing, chemical composition, and mechanical properties.

The Key Differences: A Deeper Dive

While both levels must meet the baseline requirements of API 5L, PSL2 introduces a series of stricter controls. Let’s examine the most critical differences.

1. Chemical Composition

From a metallurgical standpoint, the tighter chemical controls for PSL2 are fundamental.

- PSL2 has stricter maximum limits on key elements like carbon, phosphorus, and sulfur. It also mandates a maximum Carbon Equivalent (CEQ), which is crucial for ensuring good weldability.

- PSL1 has more relaxed chemical limits.

Why it matters: The cleaner, more tightly controlled steel required for PSL2 results in a pipe that is tougher, more weldable, and better suited for demanding service conditions, especially sour service (H₂S).

2. Mechanical Properties

This is arguably the most significant area of differentiation.

- PSL2 has mandatory minimum requirements for fracture toughness (measured by the Charpy impact test). It also has a maximum limit on the yield to tensile strength ratio.

- PSL1 has no mandatory toughness requirements (unless specified as an additional requirement by the purchaser).

Why it matters: Toughness is a material’s ability to resist the propagation of a fracture. For any pipeline where this is a significant risk—such as high-pressure gas lines or those in low-temperature environments—the mandatory toughness of PSL2 is non-negotiable for ensuring safety.

3. Manufacturing Process and Traceability

- PSL2 prohibits certain practices, such as the repair of the pipe body, which may be permissible under PSL1.

- PSL2 also requires full traceability, meaning each pipe can be traced back to the specific heat of steel from which it was made. PSL1 only requires traceability until all tests are passed.

Summary Table: PSL1 vs. PSL2 at a Glance

| Requirement | PSL1 | PSL2 |

| Chemical Composition | Standard Limits | Stricter Limits & Max CEQ |

| Impact Toughness | Not Required (unless specified) | Mandatory |

| Yield to Tensile Ratio | Not Specified | Maximum Limit is Mandatory |

| Weld Repair of Body | Permitted | Not Permitted |

| Traceability | Required until tests pass | Required throughout production |

The Allland Steel Recommendation: How to Choose

A useful rule of thumb is to consider the consequence of failure.

- Choose PSL1 for: Standard, less critical applications. This includes pipelines where operating pressures and environmental risks are moderate. It is a reliable and more economical choice for a wide range of general uses.

- Choose PSL2 for: Mission-critical applications where safety and reliability are the highest priorities. This is the required standard for:

- High-pressure gas transmission lines

- Offshore pipelines

- Pipelines in environmentally sensitive or low-temperature areas

- Sour service (H₂S) applications

The additional upfront cost for a PSL2-compliant pipe is a sound investment in long-term asset integrity and risk mitigation.

Our Commitment to Compliance

Navigating technical standards can be complex, but our team is here to assist. Allland Steel has the proven expertise and advanced manufacturing capabilities to produce LSAW and SSAW pipes that fully comply with both PSL1 and PSL2 requirements of the latest API 5L edition.

For detailed technical specifications, please visit our API 5L Standards Page.

Or Contact a Specialist at Allland Steel to ensure the pipe you order meets the precise demands of your project.

While the 3LPE coating system is well-known for its superior pipeline protection, the quality of its application is not a matter of guesswork. It is governed by rigorous international standards, and among the most respected and frequently specified is DIN 30670.

For our clients, understanding this standard is key to appreciating the level of quality, durability, and long-term reliability you receive when you specify a compliant coating. It is the benchmark that separates a standard coating from a high-performance, long-life asset protection system.

What is DIN 30670?

DIN 30670 is a technical standard issued by the DIN (Deutsches Institut für Normung), the German Institute for Standardization. It specifically outlines the requirements for factory-applied, three-layer extruded polyethylene (3LPE) coatings on steel pipes and fittings for corrosion protection.

Although German in origin, DIN 30670’s comprehensive and stringent requirements have led to its adoption as a global benchmark for quality by pipeline owners, engineers, and manufacturers worldwide.

Key Quality Parameters Regulated by DIN 30670

A commitment to the DIN 30670 standard means a commitment to verifiable performance. Here are the critical quality parameters that the standard regulates, and why they matter for your project.

1. Coating Thickness

The standard mandates a minimum thickness for the outer polyethylene layer, which varies based on the pipe’s diameter.

- Why it matters: From an asset protection standpoint, sufficient thickness is the first line of defense against physical damage. This ensures the pipe is robust enough to withstand the rigors of transportation, on-site handling, and the stresses of backfilling during installation.

2. Peel Resistance / Adhesion

This crucial test measures the force required to peel the coating from the steel substrate at specific angles and temperatures.

- Why it matters: This is a direct measure of the coating’s bond strength. Excellent adhesion across all three layers is fundamental to the system’s performance. It prevents moisture from creeping under the coating and causing corrosion. A high peel resistance value is a hallmark of a properly applied, high-integrity coating.

3. Impact Resistance

This test assesses the coating’s toughness by dropping a specified weight from a set height onto the coated pipe. Afterwards, the impact area is tested for any “holidays” (pinholes or cracks).

- Why it matters: This simulates the real-world impacts a pipe might endure during its journey from the factory to the trench. A passing result demonstrates that the coating is tough and resilient, not brittle.

4. Cathodic Disbondment

This is one of the most critical long-term performance tests. It measures the coating’s ability to resist “unsticking” from the pipe surface in the presence of an electrical current from a cathodic protection system, especially at a point of minor damage.

- Why it matters: A low cathodic disbondment value is essential for the long-term health of the pipeline. It ensures that if a small holiday does occur, the corrosion will be contained to that tiny area and will not spread underneath the coating.

The Allland Steel Commitment to Quality

Compliance with demanding standards is at the core of our manufacturing philosophy. The 3LPE coatings applied at Allland Steel are engineered and rigorously tested to meet or exceed the stringent requirements set forth in DIN 30670.

When you specify a 3LPE coating from Allland Steel, you are not just ordering a product; you are investing in a protection system that is verified against one of the world’s most trusted benchmarks for quality and long-term performance. This commitment provides our clients with peace of mind and confidence in the longevity of their critical assets.

To discuss the specific coating requirements for your next project, contact our technical specialists at Allland Steel.

In the world of carbon steel pipe, ASTM A53, ASTM A106, and API 5L are three of the most dominant standards. A common point of confusion we address for our clients is understanding their distinct purposes. While these pipes may appear similar, they are engineered for very different applications, and selecting the correct standard is a critical step in ensuring a project’s safety, compliance, and cost-effectiveness.

Our goal is to clarify the key differences between these specifications, so you can confidently choose the right material for your specific application.

The Core Purpose of Each Standard

The easiest way to understand the difference is to start with the primary application each standard was designed to serve.

- ASTM A53: This is the general-purpose “workhorse” standard for pipe. It’s primarily intended for mechanical and pressure applications, as well as ordinary uses in steam, water, gas, and air lines. Think of it as the standard for general plumbing and structural applications.

- ASTM A106: This is the high-temperature specialist. The standard is written exclusively for seamless carbon steel pipe intended for high-temperature and high-pressure service. This is the required choice for applications like power plant piping, boilers, and refineries.

- API 5L: This is the pipeline professional’s standard. It is specifically written for the oil and gas industry to govern pipe used for conveying hydrocarbons (oil, gas) and water in pipeline transportation systems.

Key Technical Differences Explained

The different purposes of these standards lead to crucial differences in their technical requirements.

1. Manufacturing Method

This is one of the most fundamental distinctions.

- ASTM A53: Can be either seamless or welded (typically ERW – Electric Resistance Welded).

- ASTM A106: Is exclusively seamless. This is a non-negotiable requirement for its intended high-temperature service, as it eliminates the weld seam as a potential point of weakness under thermal stress.

- API 5L: Can be seamless or welded (ERW, LSAW, SSAW), covering the broad range of manufacturing methods used in the pipeline industry.

2. Chemical Composition

From a materials perspective, the chemical makeup is tailored for the application.

- ASTM A106: Deliberately includes silicon (min 0.10%), which enhances its performance and strength in high-temperature environments. It also has stricter controls on elements like sulfur and phosphorus than A53.

- ASTM A53: Has more general chemical requirements.

- API 5L: Has a detailed progression of chemical requirements that become stricter with higher grades (e.g., X42, X52, X70) to ensure weldability and toughness. PSL2 specifications have particularly strict chemical controls.

3. Mechanical Properties

The strength and toughness requirements are directly linked to the intended service.

- API 5L: Offers a much wider range of strength grades (up to X80 and beyond) and places a strong emphasis on fracture toughness, which is mandatory for the PSL2 specification. This is critical for ensuring the integrity of long-distance pipelines.

- ASTM A106 & A53: Are offered in a few common grades (e.g., Grade A, B, C) with standard strength requirements and typically no mandatory toughness testing unless specified by the customer.

Summary Table: A53 vs. A106 vs. API 5L at a Glance

| Attribute | ASTM A53 | ASTM A106 | API 5L |

| Primary Application | General purpose fluid, structural | High-temperature, high-pressure service | Oil & Gas pipeline systems |

| Manufacturing Type | Seamless or Welded (ERW) | Exclusively Seamless | Seamless or Welded (All types) |

| Temperature Range | Moderate | High | Broad range, with toughness for low temps |

| Key Chemical Element | General controls | Silicon added for high-temp strength | Tightly controlled based on grade/PSL |

| Grades | Gr. A, B | Gr. A, B, C | Wide range (e.g., B, X42, X52, X60, X70) |

The Allland Steel Guidance: Making the Correct Selection

A common and dangerous mistake is to assume these standards are interchangeable. Our role as your technical partner is to ensure you receive a product that is not only certified to a standard but is the correct standard for your application.

Here is a simple decision guide:

- Is your application general purpose, such as low-pressure water, air lines, or structural supports? ASTM A53 is the correct and most economical choice.

- Is your application for high-temperature service (e.g., steam lines, process piping) and must be seamless? ASTM A106 is the mandatory and only appropriate choice.

- Are you transporting oil, gas, or water in a pipeline? API 5L is the required industry standard. Your next step will be to select the appropriate grade and PSL level.

Navigating the nuances of steel pipe standards is our expertise. The technical team at Allland Steel is available to review your project specifications and ensure your material is optimized for performance, safety, and compliance.

Contact a technical specialist at Allland Steel to discuss your project requirements.

Every great structure is built on a solid foundation. In modern civil engineering, steel pipe piles are a cornerstone of that foundation, and the standard that governs their quality and performance is ASTM A252.

A frequent point of clarification we provide for our clients in the construction and geotechnical sectors is why this specific standard is so critical. The reason is simple: pipe manufactured to the A252 standard isn’t just a hollow steel section; it’s a structural element specifically engineered to bear immense loads and ensure the stability of buildings, bridges, and marine structures for generations.

What Exactly is ASTM A252?

ASTM A252 is the official designation for the American Society for Testing and Materials’ standard specification covering welded and seamless steel pipe piles.

Its scope is very specific. It covers steel pipe that is cylindrical in shape and intended for one of two primary purposes:

- As a permanent, load-bearing component of a foundation.

- As a shell or casing to form cast-in-place concrete piles.

The key distinction to make is that A252 pipe is not intended for the transport of fluids under pressure. Its entire focus is on structural integrity and foundation performance.

Why ASTM A252 is the Ideal Choice for Piling

While other pipes might look similar, the A252 standard includes several features that make it uniquely suited for foundation work.

1. A Clear Focus on Minimum Yield Strength

From a structural engineering perspective, the most important property of a pile is its ability to handle loads without permanent deformation.

- The Standard: ASTM A252 is primarily concerned with minimum yield strength, offering three distinct grades:

- Grade 1: Minimum Yield Strength of 30 ksi (207 MPa)

- Grade 2: Minimum Yield Strength of 35 ksi (241 MPa)

- Grade 3: Minimum Yield Strength of 45 ksi (310 MPa)

- Why it matters: This allows engineers to select the precise grade that matches their design load calculations, ensuring both safety and economic efficiency.

2. Requirements for Straightness

A pile must be driven straight into the ground to perform as designed.

- The Standard: ASTM A252 contains specific tolerances for the straightness of the pipe.

- Why it matters: This ensures the pile can be driven effectively and that the load is transferred axially to the bearing soil or bedrock. A pile that is not straight could buckle under load, compromising the entire foundation.

3. Flexible Chemical Requirements for Cost-Effectiveness

This is a unique and deliberate feature of the A252 standard.

- The Standard: Unlike standards for pressure pipe (like API 5L), ASTM A252 does not have strict limits on the chemical composition of the steel, such as phosphorus content.

- Why it matters: This flexibility allows manufacturers to utilize a wider range of steel sources. Since the pipe’s primary role is to provide structural strength and not to contain high-pressure fluids or resist specific types of corrosion, these stringent chemical controls are unnecessary. This makes A252 pipe a highly economical and readily available solution for foundation work.

The Allland Steel Advantage for Piling Projects

Building a foundation you can trust for generations starts with materials you can rely on today. At Allland Steel, we manufacture high-quality LSAW and SSAW pipe piles that meet and exceed the requirements of ASTM A252 in all three grades. Our capabilities in producing large-diameter and heavy-wall pipes make us an ideal partner for major infrastructure projects.

We understand the critical role these products play. Our commitment to quality ensures that the piles we deliver will form the bedrock of a safe and successful construction project.

To discuss the piling requirements for your next bridge, building, or marine project, contact a specialist at Allland Steel.

In any industrial purchase, especially for critical materials like steel pipe, traceability and the verification of quality are paramount. The Mill Test Certificate (MTC)—also known as a Mill Test Report (MTR)—is the primary document that provides this assurance.

A common and important question we receive, particularly from clients involved in European or major international projects, relates to the EN 10204 standard. This standard is the key to understanding the different levels of material certification and what they mean for your project’s quality assurance. Our goal is to clarify what this standard entails and what you can expect from Allland Steel.

What is EN 10204?

EN 10204 is a European Standard that specifies the different types of “inspection documents” that can be provided to a purchaser for metallic products. In short, it creates a standardized, universally understood system for certifying that a product’s chemical and mechanical properties conform to the specifications of the order. It ensures that both manufacturer and buyer are speaking the same language when it comes to quality documentation.

The Key Certificate Types Explained

EN 10204 defines several document types, but in the steel pipe industry, the most relevant are Type 2.2, Type 3.1, and Type 3.2.

Type 2.2: Test Report

This is a document in which the manufacturer declares that the products are in compliance with the order and provides results of non-specific inspection. This means the test results are based on the manufacturer’s regular quality procedures and may not be from the actual batch of material being delivered.

Type 3.1: Inspection Certificate 3.1

This is the most common and widely accepted certificate for industrial applications.

- What it is: A certificate issued and validated by the manufacturer’s authorized inspection representative, who must be independent of the manufacturing department.

- What it contains: It affirms that the products are compliant with the order and, crucially, includes the specific test results from the actual batch of products being supplied.

- Why it matters: From a quality assurance perspective, the Type 3.1 certificate provides the essential, traceable link between the physical product you receive and the specific tests that prove its compliance with the required standards.

Type 3.2: Inspection Certificate 3.2

This is the highest level of certification under EN 10204.

- What it is: A Type 3.1 certificate that has also been countersigned and validated by an independent third-party inspection authority (such as Lloyd’s Register, DNV, TÜV) or the purchaser’s own authorized inspector.

- Why it’s used: This is required for the most critical applications (e.g., nuclear power, certain offshore or pressure vessel components) where project specifications demand an impartial, external validation of the manufacturer’s test results.

What Type of MTC Does Allland Steel Provide?

At Allland Steel, our standard practice for all orders requiring specific material validation is to provide a Type 3.1 Mill Test Certificate in accordance with EN 10204.

This MTC provides full traceability for your order, detailing the specific:

- Chemical composition analysis

- Mechanical properties (Yield Strength, Tensile Strength, Elongation)

- Results of any other required tests, such as impact toughness or hydrostatic tests.