Q:3LPE vs. 3LPP: How do I choose the right pipe protection?

Selecting the right anti-corrosion coating is one of the most critical decisions in ensuring a pipeline’s long-term integrity and service life. A common and important choice our clients face is between two premier coating systems: 3LPE and 3LPP.

While both are advanced, three-layer systems that offer exceptional protection, they are not interchangeable. They are engineered for different operational challenges. Our goal is to clarify these differences, enabling you to make the most reliable and cost-effective choice for your project.

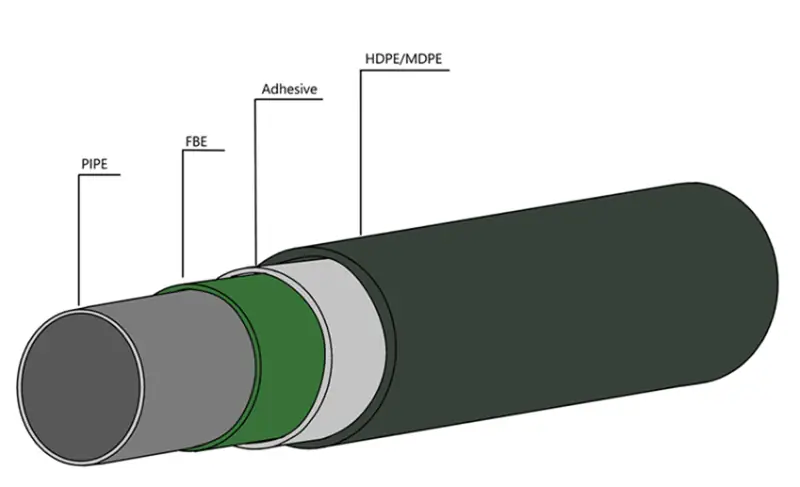

Understanding the Shared “Three-Layer” Foundation

First, it’s important to understand what the “3L” signifies. Both 3LPE and 3LPP share the same fundamental, high-performance structure:

- Layer 1: Fusion Bonded Epoxy (FBE): This primer layer is applied directly to the blasted steel surface. Its primary role is to provide excellent adhesion and act as the main barrier against corrosion.

- Layer 2: Copolymer Adhesive: This functions as the “glue,” creating a strong, chemical bond between the epoxy layer and the final topcoat.

- Layer 3: Polyolefin Topcoat: This is the outer layer that provides robust mechanical protection.

The only difference between 3LPE and 3LPP lies in the material used for this crucial third layer: Polyethylene (PE) or Polypropylene (PP). This single difference, however, dramatically changes the coating’s performance profile.

Head-to-Head: 3LPE (Polyethylene) vs. 3LPP (Polypropylene)

Let’s compare the two systems based on the factors that matter most in project design and execution.

1. Operating Temperature Resistance: The Deciding Factor

From an engineering standpoint, the operational temperature of the pipeline is the single most important factor in this decision.

- 3LPE: Is the industry standard for pipelines operating at normal temperatures. It provides reliable performance for continuous service up to 80-85°C (176-185°F).

- 3LPP: Is specifically engineered for high-temperature applications. The polypropylene topcoat gives it a significantly higher temperature resistance, making it suitable for continuous service up to 110°C (230°F) and even higher for specialized formulations.

A key principle in pipeline design is that exceeding a coating’s temperature limit can lead to accelerated aging and premature failure.

2. Mechanical Properties: Hardness and Abrasion Resistance

The outer layer must protect the pipe from damage during transportation, installation, and throughout its service life.

- 3LPP: Polypropylene is an inherently harder and more rigid material than polyethylene. This gives 3LPP superior resistance to abrasion, impact, gouging, and penetration.

- 3LPE: Offers excellent mechanical protection for most standard conditions but is a slightly softer and more flexible material.

This makes 3LPP the preferred choice for challenging installation environments, such as rocky terrains, horizontal directional drilling (HDD), or areas with significant soil stress.

Summary Table: Key Differences at a Glance

| Property | 3LPE (Three-Layer Polyethylene) | 3LPP (Three-Layer Polypropylene) |

| Max. Operating Temp. | ~85°C (185°F) | >110°C (230°F) |

| Mechanical Resistance | Excellent | Superior (Harder, more abrasion resistant) |

| Flexibility | More Flexible | More Rigid |

| Typical Application | Standard onshore/offshore oil & gas, water | High-temp pipelines, harsh terrains (HDD) |

| Relative Cost | Standard | Higher |

The Allland Steel Recommendation: Which Coating Is Right for You?

Our guidance for choosing between these two excellent systems is clear and based on your project’s specific needs:

- Choose 3LPE if: Your pipeline’s continuous operating temperature will remain below 80°C, and the installation environment is not exceptionally harsh. For a vast majority of oil, gas, and water pipelines, 3LPE provides the optimal balance of high performance, reliability, and cost-effectiveness.

- Choose 3LPP if: Your pipeline will operate at elevated temperatures (above 80°C), will be installed in a challenging or rocky environment, or requires the absolute maximum in mechanical damage resistance. While 3LPP has a higher upfront cost, it is a value-driven investment for projects where its superior resistance prevents costly future repairs and ensures long-term asset integrity.

The selection of a coating system has lasting implications. The specialists at Allland Steel can help you analyze your project’s operational data to make the most reliable and effective choice.

To learn more about our coating capabilities, please Contact a Specialist at Allland Steel.