HOT PRODUCTS TAGS

SHOULDER PIPE

SHOULDER PIPE

Outside Diameter:Φ60.3mm – 406.4mm (2″ – 16″ )

Diameter (pipe): 60.3 to 406.4 mm

Diameter (with ring): 66.5 to 419 mm

Ring Width: 16 mm to 25.5 mm

Quality Standards:AS/NZS 1074, BS 1387, EN 10255, ASTM A53, ISO 65.

description

SHOULDER PIPE is a for hot forged tubular part machined for added value with attached shoulder profiles. The process consists of billet heating, closed-die forging, quenching & tempering, and precision threaded. Ideal for high pressure applications as well as load-bearing, it offers excellent tensile strength and pressure containment. Typical uses are drilling tools, downhole tools, hydraulic cylinder and barrel, structural pivot shaft. Superior to standard pipes, it has fatigue resistance, dimensional stability, and 100% material-quality consistency through forging.

Product Name: Shouldered Tubing, Forged Shoulder Pipe, Machined Shoulder Sub

Specifications:

Outer Diameter: 60.3mm – 406.4mm (2“ – 16″)

Diameter (pipe): 60.3 to 406.4 mm

Diameter (with ring): 66.5 to 419 mm

Ring Width: 16 mm to 25.5 mm

Standard and Steel Grade:

AS/NZS 1074 , BS1387 , EN10255 , ASTM A53 , ISO65

Ends: API Threaded (BTC/LTC/STC), NPT Tapered, Square Cut, Flush Ground

Surface Treatment

QT Heat Treatment, Phosphate Coating, Black Oxide, Electroless Nickel Plating, Precision Honing

Specification

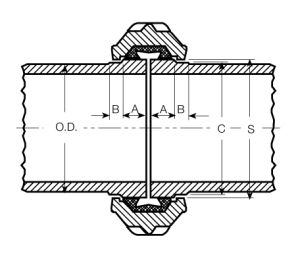

SHOULDERED PIPE DIMENSIONS

| O.D. | NPS | “DS” | Tolerance+/- | “L” | |

| mm | mm | mm | mm | mm | mm |

| 60.3 | 50 | 66.5 | 0.8 | 0.8 | 16 |

| 88.9 | 80 | 97 | 0.8 | 0.8 | 16 |

| 114.3 | 100 | 122 | 0.8 | 0.8 | 17.5 |

| 165.1 | 150 | 174.5 | 0.8 | 0.8 | 17.5 |

| 168.3 | 150 | 178 | 0.8 | 0.8 | 17.5 |

| 219.1 | 200 | 232 | 0.8 | 1.4 | 20.5 |

DIMENSIONSAND SIZES OFRINGS ON SHOULDEREDPIPE

| O.D. | NPS | Ring I.D. | Ring O.D. | Tolerance+/- | Ring Width | |

| mm | mm | mm | mm | mm | mm | width |

| 60.3 | 50 | 60.3 | 66.5 | 0.8 | 0.8 | 16 |

| 88.9 | 80 | 88.9 | 97 | 0.8 | 0.8 | 16 |

| 114.3 | 100 | 114.3 | 122 | 0.8 | 0.8 | 17.5 |

| 139.7 | 125 | 139.7 | 149 | 0.8 | 0.8 | 17.5 |

| 165.1 | 150 | 165.1 | 174.5 | 0.8 | 0.8 | 17.5 |

| 168.3 | 150 | 168.3 | 178 | 0.8 | 0.8 | 17.5 |

| 219.1 | 200 | 219.1 | 232 | 0.8 | 1.4 | 20.5 |

| 273 | 250 | 273 | 286 | 0.8 | 1.9 | 20.5 |

| 323.9 | 300 | 323.9 | 336.5 | 0.8 | 2.4 | 20.5 |

| 355.6 | 350 | 355.6 | 368.5 | 0.8 | 2.4 | 24 |

| 406.4 | 400 | 406.4 | 419 | 0.8 | 2.4 | 25.5 |

| 457 | 450 | 457 | 470 | 0.8 | 2.4 | 25.5 |

WORKING&TEST PRESSURES SHOULDERED PIPE

| O.D. | W.T. | MaxWorkingPressure | MaxTestPressure |

| mm | mm | mpa | mpa |

| 60.3 | 2 | 8.8 | 19 |

| 88.9 | 2 | 5.6 | 12 |

| 114.3 | 2 | 5.6 | 10 |

| 165.1 | 2.5 | 4.2 | 8.8 |

| 219.1 | 3.2 | 3.8 | 8 |

| 323.9 | 4.8 | 2.9 | 4.35 |

| 355.6 | 4.8 | 2.6 | 3.9 |

| 457.0 | 4.8 | 2.0 | 3.1 |

| 610.0 | 6.0 | 1.9 | 2.9 |

application

SHOULDER PIPE delivers critical performance in high-stress environments:

Oil & Gas Drilling: Drilling jar components, heavy-weight drill pipe subs, liner hanger systems, and blowout preventer (BOP) adapters requiring pressure integrity.

Hydraulic Systems: Cylinder barrels for injection molding machines, hydraulic presses, and offshore crane systems with ISO 10100 fatigue rating compliance.

Mining Equipment: Shaft couplings for rock drills, wear sleeves for conveyor systems, and pivot pins for excavator booms.

Power Generation: Turbine shaft linkages, steam valve stems, and boiler feed pump bushings in high-temperature service.

Industrial Machinery: Drive shafts for extruders, precision guides for CNC equipment, and reinforcement sleeves for high-torque gearboxes.

advantages

Extreme Torque Capacity

Highly robust alloy steel that is precision hardened, even under the most extreme drilling conditions this sdp.Plus does not give in, keeping its shape and allowing for maximum power transmission.

Superior Fatigue Resistance

High-strength heat treatment provides improved durability characteristics under high-load, surface pressure drilling conditions, such as deep well drilling.

Leak-Proof Sealing Guarantee

CNC machined API/Premium threads provide excellent sealing ability at high pressures.

Abrasion & Corrosion Defense

Surface-hardened and multi-layer coated to battle the full gamut of wear in abrasive wells.

Global Standard Compliance

Complete API/ISO certification ensures our tools are fully compatible with all drilling systems.

Operational Cost Efficiency

Increased longevity and less maintenance reduced overall drilling cost per a meter.

packing

Shoulder pipes require anti-impact protection during transit. Each pipe is coated with VCI rust inhibitor, wrapped in polyethylene film, and mounted in custom crates with wooden spacers. Pipe ends are secured with threaded protectors (API Type III). Ocean transport options include:

Flat Rack Containers (for oversized pieces)

Palletized Air Freight (urgent shipments)

Dedicated Pipe Carriers with shock sensors (premium service)

Bulk shipments include moisture indicator cards and desiccant packs in sealed packaging. Maximum stack height: 3 layers with interlayer dunnage.

SHOULDERED PIPE DIMENSIONS

| O.D. | NPS | “DS” | Tolerance+/- | “L” | |

| mm | mm | mm | mm | mm | mm |

| 60.3 | 50 | 66.5 | 0.8 | 0.8 | 16 |

| 88.9 | 80 | 97 | 0.8 | 0.8 | 16 |

| 114.3 | 100 | 122 | 0.8 | 0.8 | 17.5 |

| 165.1 | 150 | 174.5 | 0.8 | 0.8 | 17.5 |

| 168.3 | 150 | 178 | 0.8 | 0.8 | 17.5 |

| 219.1 | 200 | 232 | 0.8 | 1.4 | 20.5 |

DIMENSIONSAND SIZES OFRINGS ON SHOULDEREDPIPE

| O.D. | NPS | Ring I.D. | Ring O.D. | Tolerance+/- | Ring Width | |

| mm | mm | mm | mm | mm | mm | width |

| 60.3 | 50 | 60.3 | 66.5 | 0.8 | 0.8 | 16 |

| 88.9 | 80 | 88.9 | 97 | 0.8 | 0.8 | 16 |

| 114.3 | 100 | 114.3 | 122 | 0.8 | 0.8 | 17.5 |

| 139.7 | 125 | 139.7 | 149 | 0.8 | 0.8 | 17.5 |

| 165.1 | 150 | 165.1 | 174.5 | 0.8 | 0.8 | 17.5 |

| 168.3 | 150 | 168.3 | 178 | 0.8 | 0.8 | 17.5 |

| 219.1 | 200 | 219.1 | 232 | 0.8 | 1.4 | 20.5 |

| 273 | 250 | 273 | 286 | 0.8 | 1.9 | 20.5 |

| 323.9 | 300 | 323.9 | 336.5 | 0.8 | 2.4 | 20.5 |

| 355.6 | 350 | 355.6 | 368.5 | 0.8 | 2.4 | 24 |

| 406.4 | 400 | 406.4 | 419 | 0.8 | 2.4 | 25.5 |

| 457 | 450 | 457 | 470 | 0.8 | 2.4 | 25.5 |

WORKING&TEST PRESSURES SHOULDERED PIPE

| O.D. | W.T. | MaxWorkingPressure | MaxTestPressure |

| mm | mm | mpa | mpa |

| 60.3 | 2 | 8.8 | 19 |

| 88.9 | 2 | 5.6 | 12 |

| 114.3 | 2 | 5.6 | 10 |

| 165.1 | 2.5 | 4.2 | 8.8 |

| 219.1 | 3.2 | 3.8 | 8 |

| 323.9 | 4.8 | 2.9 | 4.35 |

| 355.6 | 4.8 | 2.6 | 3.9 |

| 457.0 | 4.8 | 2.0 | 3.1 |

| 610.0 | 6.0 | 1.9 | 2.9 |

SHOULDER PIPE delivers critical performance in high-stress environments:

Oil & Gas Drilling: Drilling jar components, heavy-weight drill pipe subs, liner hanger systems, and blowout preventer (BOP) adapters requiring pressure integrity.

Hydraulic Systems: Cylinder barrels for injection molding machines, hydraulic presses, and offshore crane systems with ISO 10100 fatigue rating compliance.

Mining Equipment: Shaft couplings for rock drills, wear sleeves for conveyor systems, and pivot pins for excavator booms.

Power Generation: Turbine shaft linkages, steam valve stems, and boiler feed pump bushings in high-temperature service.

Industrial Machinery: Drive shafts for extruders, precision guides for CNC equipment, and reinforcement sleeves for high-torque gearboxes.

Extreme Torque Capacity

Highly robust alloy steel that is precision hardened, even under the most extreme drilling conditions this sdp.Plus does not give in, keeping its shape and allowing for maximum power transmission.

Superior Fatigue Resistance

High-strength heat treatment provides improved durability characteristics under high-load, surface pressure drilling conditions, such as deep well drilling.

Leak-Proof Sealing Guarantee

CNC machined API/Premium threads provide excellent sealing ability at high pressures.

Abrasion & Corrosion Defense

Surface-hardened and multi-layer coated to battle the full gamut of wear in abrasive wells.

Global Standard Compliance

Complete API/ISO certification ensures our tools are fully compatible with all drilling systems.

Operational Cost Efficiency

Increased longevity and less maintenance reduced overall drilling cost per a meter.

Shoulder pipes require anti-impact protection during transit. Each pipe is coated with VCI rust inhibitor, wrapped in polyethylene film, and mounted in custom crates with wooden spacers. Pipe ends are secured with threaded protectors (API Type III). Ocean transport options include:

Flat Rack Containers (for oversized pieces)

Palletized Air Freight (urgent shipments)

Dedicated Pipe Carriers with shock sensors (premium service)

Bulk shipments include moisture indicator cards and desiccant packs in sealed packaging. Maximum stack height: 3 layers with interlayer dunnage.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.