HOT PRODUCTS TAGS

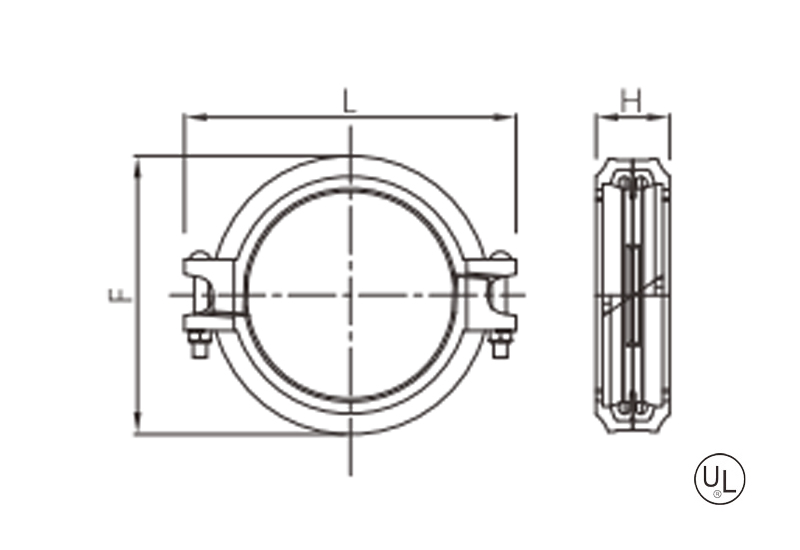

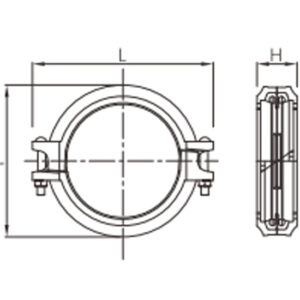

Heavy-duty rigid grooved coupling

·Standard: ANSI / UL 213C UL

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″ – 12″

description

Heavy-duty rigid grooved couplings are high-strength rigid pipe fittings with grooved connection structures, used in pipeline systems with high load-bearing requirements

Specification

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 88 | 136 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

2-1/2″ | 65 | 73.0 | 101 | 150 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

2-1/2″ | 65 | 76.1 | 104 | 155 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

3″ | 80 | 88.9 | 121 | 174 | 46 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

4″ | 100 | 114.3 | 150 | 217 | 50 | 2 – 5/8″ × 80 | 2 – M16 × 80 |

5″ | 125 | 139.7 | 179 | 249 | 52 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

5″ | 125 | 141.3 | 180 | 250 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 165.1 | 208 | 281 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 168.3 | 211 | 285 | 52 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

8″ | 200 | 219.1 | 269 | 358 | 61 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

10″ | 250 | 273.0 | 326 | 420 | 63 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

12″ | 300 | 323.9 | 385 | 481 | 66 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

application

- Designed for high pressure:high load- critical load-bearing pipelines, e.g., fire main pipes, industrial water/oil main lines, larger HVAC pipe systems

- High Stability: This scenarios type will be used relatively in rigid connection points where there is no movement allowed, for instances such as pipe supports and direct valve connections, or even risers in high-rise buildings.

- Harsh Environments: This component meets the rigorous UL 213C certification, which makes it especially suitable for the most demanding applications in terms of safety, such as fire safety and processing chemicals.

- Flexible pipeline: Pipesize: DN50-DN300 2-12 inch, suitable for threaded end face pipes such as steel pipes and ductile iron pipes

advantages

1. Perfect stability:this type of connection is capable of withstanding great pressure and load that would make it immoveable.

2. No displacement to absolute zero:There is absolutely no risk of slippage or displacement due to vibration or temperature change, maintaining stability in the long term.

3. High Pressure Leak Free: The seal has a high-pressure safety, which is designed for long-term operation under extreme pressure conditions without leaking and guaranteeing system safety.

4. Cool installation that saves time and is more efficient: Uses groove connections rather than welding. Installation is fast and achieved simply by tightening bolts.

5. Corrosion-resistant surface treatment (red paint or galvanisation) and robust materials make it rustproof, wear-resistant as well as long-lasting.

6. Easy Maintenance: designed to easily dismantle and replace components (eg. gaskets) without cutting or destroying the pipeline, so that convenient user-friendly maintenance can be achieved, saving cost of maintenenace too!

packing

- Standard Protective Packaging:

- Each pipe fitting is individually boxed, including a chemical absorbent,moisture-repellant pack, and basic installation information

- The product name, size and working pressure are printed on the exterior of the box (ie; Heavy-Duty Rigid Coupling, 6 inch, High Pressure).

- Reinforced Packaging for Large Sizes:

- Large size pipe fittings 8 inches and above are custom packed in the wooden crates that are filled with foam etc. to prevent any damage from wear & tear.

- Bulk Shipping:

- The fittings are stacked neatly on solid pallets and tied with stretch film or steel straps so that they can be carried by a forklift and suitably transported by sea or land across long distances.

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 88 | 136 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

2-1/2″ | 65 | 73.0 | 101 | 150 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

2-1/2″ | 65 | 76.1 | 104 | 155 | 45 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

3″ | 80 | 88.9 | 121 | 174 | 46 | 2 – 1/2″ × 75 | 2 – M12 × 75 |

4″ | 100 | 114.3 | 150 | 217 | 50 | 2 – 5/8″ × 80 | 2 – M16 × 80 |

5″ | 125 | 139.7 | 179 | 249 | 52 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

5″ | 125 | 141.3 | 180 | 250 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 165.1 | 208 | 281 | 51 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

6″ | 150 | 168.3 | 211 | 285 | 52 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

8″ | 200 | 219.1 | 269 | 358 | 61 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

10″ | 250 | 273.0 | 326 | 420 | 63 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

12″ | 300 | 323.9 | 385 | 481 | 66 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

- Designed for high pressure:high load- critical load-bearing pipelines, e.g., fire main pipes, industrial water/oil main lines, larger HVAC pipe systems

- High Stability: This scenarios type will be used relatively in rigid connection points where there is no movement allowed, for instances such as pipe supports and direct valve connections, or even risers in high-rise buildings.

- Harsh Environments: This component meets the rigorous UL 213C certification, which makes it especially suitable for the most demanding applications in terms of safety, such as fire safety and processing chemicals.

- Flexible pipeline: Pipesize: DN50-DN300 2-12 inch, suitable for threaded end face pipes such as steel pipes and ductile iron pipes

1. Perfect stability:this type of connection is capable of withstanding great pressure and load that would make it immoveable.

2. No displacement to absolute zero:There is absolutely no risk of slippage or displacement due to vibration or temperature change, maintaining stability in the long term.

3. High Pressure Leak Free: The seal has a high-pressure safety, which is designed for long-term operation under extreme pressure conditions without leaking and guaranteeing system safety.

4. Cool installation that saves time and is more efficient: Uses groove connections rather than welding. Installation is fast and achieved simply by tightening bolts.

5. Corrosion-resistant surface treatment (red paint or galvanisation) and robust materials make it rustproof, wear-resistant as well as long-lasting.

6. Easy Maintenance: designed to easily dismantle and replace components (eg. gaskets) without cutting or destroying the pipeline, so that convenient user-friendly maintenance can be achieved, saving cost of maintenenace too!

- Standard Protective Packaging:

- Each pipe fitting is individually boxed, including a chemical absorbent,moisture-repellant pack, and basic installation information

- The product name, size and working pressure are printed on the exterior of the box (ie; Heavy-Duty Rigid Coupling, 6 inch, High Pressure).

- Reinforced Packaging for Large Sizes:

- Large size pipe fittings 8 inches and above are custom packed in the wooden crates that are filled with foam etc. to prevent any damage from wear & tear.

- Bulk Shipping:

- The fittings are stacked neatly on solid pallets and tied with stretch film or steel straps so that they can be carried by a forklift and suitably transported by sea or land across long distances.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.