HOT PRODUCTS TAGS

Transition HDPE to steel coupling

·Standard: ANSI / UL 213 ISO

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 300 – 500 psi

· Connection:

Plain end HDPE pipe (SDR range

32.5 ~ 7.3) to grooved pipe, fittings

·Surface: Red painting / hot dip galvanized

·Range: 2″ – 10″

description

Transition HDPE to steel coupling is a transitional connection piece used to connect HDPE pipes and steel pipes, achieving a sealed connection of pipes of different materials

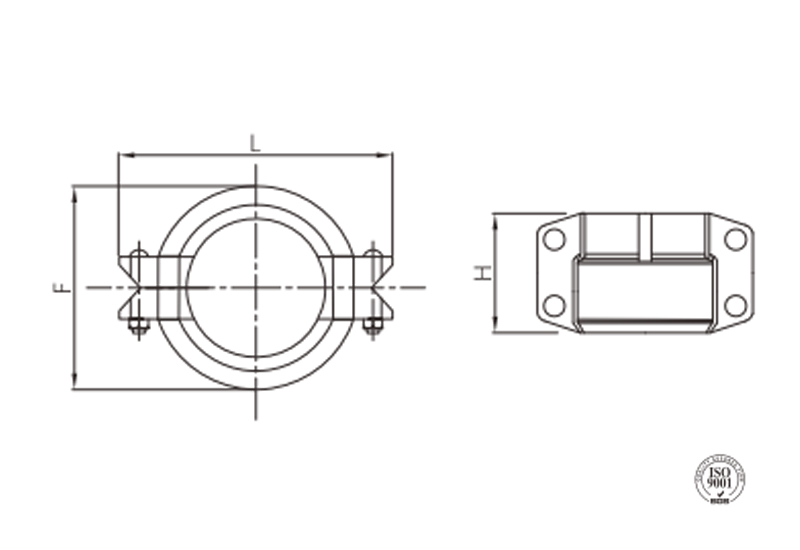

Specification

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 84 | 146 | 78 | 4 – 3/8” × 55 | 4 – M10 × 55 |

3″ | 80 | 88.9 | 112 | 174 | 79 | 4 – 1/2” × 75 | 4 – M12 × 75 |

4″ | 100 | 114.0 | 142 | 208 | 95 | 4 – 1/2” × 75 | 4 – M12 × 75 |

6″ | 150 | 168.3 | 198 | 280 | 96 | 4 – 5/8” × 85 | 4 – M16 × 85 |

8″ | 200 | 219.1 | 260 | 342 | 107 | 4 – 5/8” × 85 | 4 – M16 × 85 |

10″ | 250 | 273.0 | 314 | 424 | 128 | 4 – 3/4” × 120 | 4 – M20 × 120 |

application

- Cross-material pipe connections: For use in mixed connection systems between HDPE plastic pipes and steel/cast iron pipes, such as chemical plant renovations or upgrading of municipal pipelines, or expanding irrigation systems.

- Connection between new and old pipes: Serves as a transition layer to help prevent the need for entire piping system replacements, which can be costly and time-consuming.

- Highly corrosive application areas: ideal for highly corrosive environments of wastewater treatment plants, the coastal plants, using HDPE as a top and bottom section due to its corrosion resistance with metal section in central parts for pressure containment.

- Common mainstream pipe diameter support: Allows the pipe diameter to be converted from 2 inches to 10 inches (DN50-DN250) without any problem with the engineering.

advantages

1. Zero-leakage connection between dissimilar materials: A special sealing structure addresses the difference in thermal expansion rates between plastic and metal, completely preventing water and chemical medium leakage.

2. Dual corrosion protection: HDPE end resistant to acids and alkalis + metal end with anti-rust coating, suitable for highly corrosive environments, extending service life by 3 times.

3. Time-saving and labor-saving installation: No professional welding required; mechanical bolt fastening is sufficient, reducing construction difficulty and costs.

4. Earthquake-resistant and anti-disconnection: Flexible design cushions foundation settlement or vibration stress, preventing joint loosening or rupture.

5. One joint for multiple uses: Compatible with standard HDPE pipes (flat ends) and steel pipes (grooved ends) from different manufacturers, reducing the variety of spare parts required.

6. Ultra-long maintenance-free: Material designed to match the lifespan of the pipeline, requiring no maintenance for 20 years when buried underground.

packing

- Dual-end differentiated protection:

- The HDPE interface side is fully covered with soft foam, and the metal groove end is reinforced with hard corner guards to prevent transportation impacts.

- The outer box is clearly labeled: HDPE-to-steel joint, 6 inches × 150 mm, with an installation diagram included.

- Large-size reinforced packaging:

- For sizes 6 inches and above, a split wooden box is used to isolate and protect the two ends with irregular structures.

- Moisture-proof maritime transport solution:

- Vacuum-sealed film + desiccant, with pallet wrap film fully covering the package, suitable for the humid conditions of long-distance maritime transport.

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

2″ | 50 | 60.3 | 84 | 146 | 78 | 4 – 3/8” × 55 | 4 – M10 × 55 |

3″ | 80 | 88.9 | 112 | 174 | 79 | 4 – 1/2” × 75 | 4 – M12 × 75 |

4″ | 100 | 114.0 | 142 | 208 | 95 | 4 – 1/2” × 75 | 4 – M12 × 75 |

6″ | 150 | 168.3 | 198 | 280 | 96 | 4 – 5/8” × 85 | 4 – M16 × 85 |

8″ | 200 | 219.1 | 260 | 342 | 107 | 4 – 5/8” × 85 | 4 – M16 × 85 |

10″ | 250 | 273.0 | 314 | 424 | 128 | 4 – 3/4” × 120 | 4 – M20 × 120 |

- Cross-material pipe connections: For use in mixed connection systems between HDPE plastic pipes and steel/cast iron pipes, such as chemical plant renovations or upgrading of municipal pipelines, or expanding irrigation systems.

- Connection between new and old pipes: Serves as a transition layer to help prevent the need for entire piping system replacements, which can be costly and time-consuming.

- Highly corrosive application areas: ideal for highly corrosive environments of wastewater treatment plants, the coastal plants, using HDPE as a top and bottom section due to its corrosion resistance with metal section in central parts for pressure containment.

- Common mainstream pipe diameter support: Allows the pipe diameter to be converted from 2 inches to 10 inches (DN50-DN250) without any problem with the engineering.

1. Zero-leakage connection between dissimilar materials: A special sealing structure addresses the difference in thermal expansion rates between plastic and metal, completely preventing water and chemical medium leakage.

2. Dual corrosion protection: HDPE end resistant to acids and alkalis + metal end with anti-rust coating, suitable for highly corrosive environments, extending service life by 3 times.

3. Time-saving and labor-saving installation: No professional welding required; mechanical bolt fastening is sufficient, reducing construction difficulty and costs.

4. Earthquake-resistant and anti-disconnection: Flexible design cushions foundation settlement or vibration stress, preventing joint loosening or rupture.

5. One joint for multiple uses: Compatible with standard HDPE pipes (flat ends) and steel pipes (grooved ends) from different manufacturers, reducing the variety of spare parts required.

6. Ultra-long maintenance-free: Material designed to match the lifespan of the pipeline, requiring no maintenance for 20 years when buried underground.

- Dual-end differentiated protection:

- The HDPE interface side is fully covered with soft foam, and the metal groove end is reinforced with hard corner guards to prevent transportation impacts.

- The outer box is clearly labeled: HDPE-to-steel joint, 6 inches × 150 mm, with an installation diagram included.

- Large-size reinforced packaging:

- For sizes 6 inches and above, a split wooden box is used to isolate and protect the two ends with irregular structures.

- Moisture-proof maritime transport solution:

- Vacuum-sealed film + desiccant, with pallet wrap film fully covering the package, suitable for the humid conditions of long-distance maritime transport.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.