HOT PRODUCTS TAGS

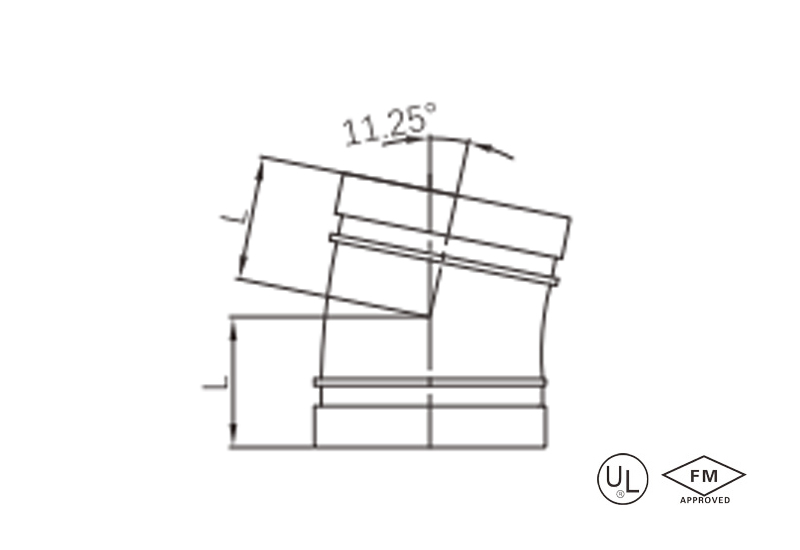

Grooved 11.25° elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Standard radius

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 12″

description

Grooved 11.25° elbow is a 11.25-degree elbow pipe fitting with a grooved connection structure, which enables the pipe to turn 11.25 degrees

Specification

Available size

| Size | Center to end | ||

| Inch | DN | mm | L(mm) |

| 1″ | 25 | 33.7 | 35 |

| 1-1/4″ | 32 | 42.4 | 35 |

| 1-1/2″ | 40 | 48.3 | 35 |

| 2″ | 50 | 60.3 | 35 |

| 2-1/2″ | 65 | 73.0 | 38 |

| 2-1/2″ | 65 | 76.1 | 38 |

| 3″ | 80 | 88.9 | 38 |

| 4″ | 100 | 114.3 | 48 |

| 5″ | 125 | 139.7 | 51 |

| 6″ | 150 | 165.1 | 51 |

| 6″ | 150 | 168.3 | 51 |

| 8″ | 200 | 219.1 | 51 |

| 10″ | 250 | 273.0 | 54 |

| 12″ | 300 | 323.9 | 57 |

application

- Precision flow direction fine-tuning: Used in high-precision fluid control systems (such as semiconductor factory cooling pipelines and laboratory medium delivery systems) to achieve millimeter-level angle calibration.

- Composite elbow alternative solution: In long-distance pipelines, multiple 11.25° elbows are combined to replace a single 45°/90° elbow, eliminating turbulence and noise caused by sharp bends.

- Vibration-sensitive applications: Compressor rooms, precision instrument connection pipes, where minimal angle turns reduce fluid pulsation impact on equipment.

- Compact equipment integration: Ship engine rooms, mobile generator sets, where minimal turning radius saves 50% installation space.

- Energy system optimization: Geothermal pipelines, solar thermal networks, where smooth turns reduce thermal energy transmission pressure loss.

advantages

- Ultra-low flow resistance design: only 15% of the 90°elbow, which can save a lot of energy in the system.

- No-Error Steering: With the average bending radius, angular precision up to ±5° decreases pipe strain deformation.

- High pressure fit: 500 psi pressure seal with superior water hammer resistance is an A536 ductile iron housing.

- Complete scenario corrosion protection:Hot-dip galvanized version with 1000 hours of salt spray resistance suitable for coastal power plants and chemical plants, and red paint version certified by FM meets the requirements of fire protection system anti-corrosion.

- Unprecedented compatibility: can join any make of grooved fittings, in less than 12 times the time required to weld a similar system

packing

- Intelligent Packaging System:

- ≤3 inches: 24 pieces per box, each piece individually packaged in a PE bag with desiccant, and angle positioning slots embedded in the cardboard box;

- >3 inches: Single-piece suspended wooden box, with a spacing of ≥50mm between the elbow and the box body filled with cushioning foam.

- Anti-confusion design:

- Product neck ring laser-engraved with a permanent “11.25°” mark;

- Outer box labeled with a prominent orange tag (to distinguish from 22.5°/45° elbows).

- Transportation protection technology:

- Groove recesses embedded with memory foam cores for pressure resistance and deformation prevention;

- NFC chip inside the box; touch with a smartphone to verify authenticity and pressure rating.

- Large Item Safety Solution:

- 8“-12” elbows use a removable steel frame with casters on the bottom;

- Each item comes with a unique ID label; scan to obtain installation torque parameters.

Available size

| Size | Center to end | ||

| Inch | DN | mm | L(mm) |

| 1″ | 25 | 33.7 | 35 |

| 1-1/4″ | 32 | 42.4 | 35 |

| 1-1/2″ | 40 | 48.3 | 35 |

| 2″ | 50 | 60.3 | 35 |

| 2-1/2″ | 65 | 73.0 | 38 |

| 2-1/2″ | 65 | 76.1 | 38 |

| 3″ | 80 | 88.9 | 38 |

| 4″ | 100 | 114.3 | 48 |

| 5″ | 125 | 139.7 | 51 |

| 6″ | 150 | 165.1 | 51 |

| 6″ | 150 | 168.3 | 51 |

| 8″ | 200 | 219.1 | 51 |

| 10″ | 250 | 273.0 | 54 |

| 12″ | 300 | 323.9 | 57 |

- Precision flow direction fine-tuning: Used in high-precision fluid control systems (such as semiconductor factory cooling pipelines and laboratory medium delivery systems) to achieve millimeter-level angle calibration.

- Composite elbow alternative solution: In long-distance pipelines, multiple 11.25° elbows are combined to replace a single 45°/90° elbow, eliminating turbulence and noise caused by sharp bends.

- Vibration-sensitive applications: Compressor rooms, precision instrument connection pipes, where minimal angle turns reduce fluid pulsation impact on equipment.

- Compact equipment integration: Ship engine rooms, mobile generator sets, where minimal turning radius saves 50% installation space.

- Energy system optimization: Geothermal pipelines, solar thermal networks, where smooth turns reduce thermal energy transmission pressure loss.

- Ultra-low flow resistance design: only 15% of the 90°elbow, which can save a lot of energy in the system.

- No-Error Steering: With the average bending radius, angular precision up to ±5° decreases pipe strain deformation.

- High pressure fit: 500 psi pressure seal with superior water hammer resistance is an A536 ductile iron housing.

- Complete scenario corrosion protection:Hot-dip galvanized version with 1000 hours of salt spray resistance suitable for coastal power plants and chemical plants, and red paint version certified by FM meets the requirements of fire protection system anti-corrosion.

- Unprecedented compatibility: can join any make of grooved fittings, in less than 12 times the time required to weld a similar system

- Intelligent Packaging System:

- ≤3 inches: 24 pieces per box, each piece individually packaged in a PE bag with desiccant, and angle positioning slots embedded in the cardboard box;

- >3 inches: Single-piece suspended wooden box, with a spacing of ≥50mm between the elbow and the box body filled with cushioning foam.

- Anti-confusion design:

- Product neck ring laser-engraved with a permanent “11.25°” mark;

- Outer box labeled with a prominent orange tag (to distinguish from 22.5°/45° elbows).

- Transportation protection technology:

- Groove recesses embedded with memory foam cores for pressure resistance and deformation prevention;

- NFC chip inside the box; touch with a smartphone to verify authenticity and pressure rating.

- Large Item Safety Solution:

- 8“-12” elbows use a removable steel frame with casters on the bottom;

- Each item comes with a unique ID label; scan to obtain installation torque parameters.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.