HOT PRODUCTS TAGS

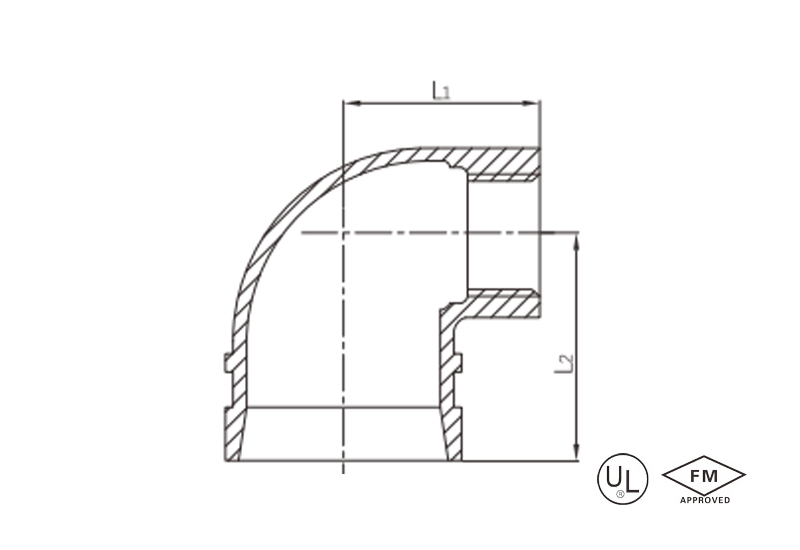

Grooved 90° reducing elbow with female threaded outlet

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Thread run: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4″x1/2″ – 3″×1″

description

Grooved 90° reducing elbow with female threaded outlet is a 90-degree grooved reducing elbow. One end is grooved connection and the other end is an internal thread interface with different pipe diameters. It is used to simultaneously achieve pipe rotation, diameter change and connection with external thread components.

Specification

Available size

Size | Center to end,L(mm) | |||

Inch | DN | mm | L1 | L2 |

1-1/4″ × 1/2″ | 32 × 15 | 42.4 × 21.3 | 35.1 | 44.5 |

1-1/4″ × 3/4″ | 32 × 20 | 42.4 × 26.9 | 34.9 | 47.6 |

1-1/4″ × 1″ | 32 × 25 | 42.4 × 33.7 | 38.1 | 51.6 |

1-1/2″ × 1/2″ | 40 × 15 | 48.3 × 21.3 | 34.9 | 44.5 |

1-1/2″ × 3/4″ | 40 × 20 | 48.3 × 26.9 | 34.9 | 47.6 |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 38.1 | 51.6 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 41.4 | 44.5 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 41.3 | 47.6 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 44.5 | 51.6 |

2-1/2″ × 3/4″ | 65 × 20 | 73.0 × 26.9 | 46 | 47.6 |

2-1/2″ ×1″ | 65 × 25 | 73.0 × 33.7 | 49.2 | 51.6 |

3″ × 3/4″ | 80 × 20 | 88.9 × 26.9 | 60.3 | 52.4 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 63.5 | 52.4 |

application

- Fire protection system branch piping: This is where an interface screws into these sprinkler heads or sensors, providing a quick connect to monitoring equipment.

- Confined space piping: For instance, in a machine room pipe compartments there are groups three parts: elbow, diameter change pipe and thread joint have to be utilized compact structure.

- Temporary piping: Groove connections allow for temporary disassembly and reassembly suited to maintenance or slab penetration.

- Painting medium transport: hot galvanizing can resist the corrosion of acid, alkali painting water treatment and chemical additives pipeline

advantages

1. Eliminates leak path vs. elbow + reducer + threaded adapter → lower cost to install

2. Standard compatibility: The internal thread is NPT/BSPT, and can be directly connected with the external threaded components such as pressure gauges & safety valves.

3. Strength Assurance: Ductile iron material (ASTM A536) resists water hammer impacts, eliminating any possibility of damage to the pipe.

4. Corrosion resistance, when it is in a humid temperature environment and high temperature may also cause changes from corrosion red paint coating layer thickness of 80μm.

packing

- Individual protection: Apply anti-rust oil to threaded ports and cover with silicone caps. Fill grooves and recesses with foam strips to prevent collision and deformation.

- Categorized packaging:

- ≤2 inches: 12 pieces per box, with internal compartments and PE bags for individual packaging;

- ≥2.5 inches: Customized top-and-bottom lid cardboard boxes for individual pieces, with corner protectors on edges.

- Transportation Markings:

- Boxes are spray-printed with an “↑” to indicate flow direction and labeled with a “Do Not Press Threaded End” warning;

- Wooden pallets are secured with steel straps, with a maximum height of 1.2 meters per pallet to prevent tipping.

- Traceability Management: Outer box labels include model number, batch number, and production date, with QR code scanning for traceability.

Available size

Size | Center to end,L(mm) | |||

Inch | DN | mm | L1 | L2 |

1-1/4″ × 1/2″ | 32 × 15 | 42.4 × 21.3 | 35.1 | 44.5 |

1-1/4″ × 3/4″ | 32 × 20 | 42.4 × 26.9 | 34.9 | 47.6 |

1-1/4″ × 1″ | 32 × 25 | 42.4 × 33.7 | 38.1 | 51.6 |

1-1/2″ × 1/2″ | 40 × 15 | 48.3 × 21.3 | 34.9 | 44.5 |

1-1/2″ × 3/4″ | 40 × 20 | 48.3 × 26.9 | 34.9 | 47.6 |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 38.1 | 51.6 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 41.4 | 44.5 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 41.3 | 47.6 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 44.5 | 51.6 |

2-1/2″ × 3/4″ | 65 × 20 | 73.0 × 26.9 | 46 | 47.6 |

2-1/2″ ×1″ | 65 × 25 | 73.0 × 33.7 | 49.2 | 51.6 |

3″ × 3/4″ | 80 × 20 | 88.9 × 26.9 | 60.3 | 52.4 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 63.5 | 52.4 |

- Fire protection system branch piping: This is where an interface screws into these sprinkler heads or sensors, providing a quick connect to monitoring equipment.

- Confined space piping: For instance, in a machine room pipe compartments there are groups three parts: elbow, diameter change pipe and thread joint have to be utilized compact structure.

- Temporary piping: Groove connections allow for temporary disassembly and reassembly suited to maintenance or slab penetration.

- Painting medium transport: hot galvanizing can resist the corrosion of acid, alkali painting water treatment and chemical additives pipeline

1. Eliminates leak path vs. elbow + reducer + threaded adapter → lower cost to install

2. Standard compatibility: The internal thread is NPT/BSPT, and can be directly connected with the external threaded components such as pressure gauges & safety valves.

3. Strength Assurance: Ductile iron material (ASTM A536) resists water hammer impacts, eliminating any possibility of damage to the pipe.

4. Corrosion resistance, when it is in a humid temperature environment and high temperature may also cause changes from corrosion red paint coating layer thickness of 80μm.

- Individual protection: Apply anti-rust oil to threaded ports and cover with silicone caps. Fill grooves and recesses with foam strips to prevent collision and deformation.

- Categorized packaging:

- ≤2 inches: 12 pieces per box, with internal compartments and PE bags for individual packaging;

- ≥2.5 inches: Customized top-and-bottom lid cardboard boxes for individual pieces, with corner protectors on edges.

- Transportation Markings:

- Boxes are spray-printed with an “↑” to indicate flow direction and labeled with a “Do Not Press Threaded End” warning;

- Wooden pallets are secured with steel straps, with a maximum height of 1.2 meters per pallet to prevent tipping.

- Traceability Management: Outer box labels include model number, batch number, and production date, with QR code scanning for traceability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.