HOT PRODUCTS TAGS

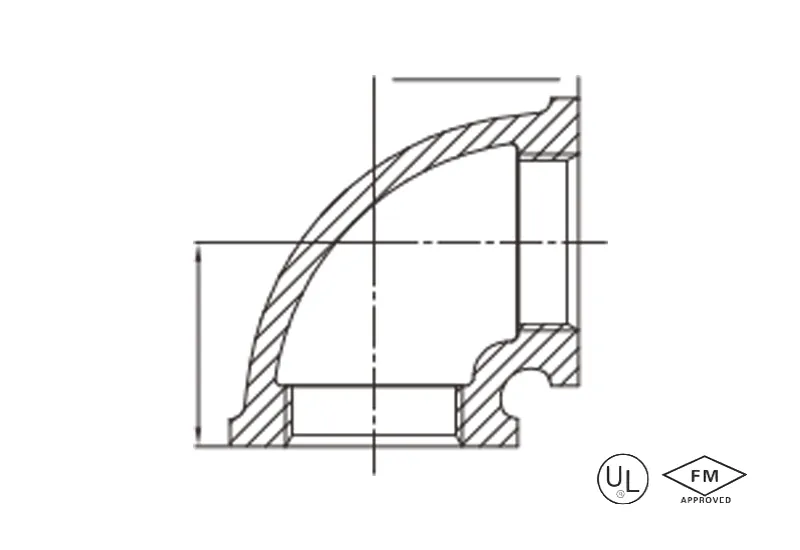

Malleable cast iron 90° reducing elbow

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″-6″

description

It is suitable for water supply and drainage, gas transportation, and industrial pipeline systems, used to make a right-angle turn in pipelines and ensure smooth fluid conveyance.

Specification

Available size

| SIZE | A | ||

| INCH | DN | MM | MM |

| 1/4″ | 8 | 13.5 | 21 |

| 3/8″ | 10 | 17.2 | 25 |

| 1/2″ | 15 | 21.3 | 28 |

| 3/4″ | 20 | 26.9 | 33 |

| 1″ | 25 | 33.7 | 38 |

| 1-1/4″ | 32 | 42.4 | 45 |

| 1-1/2″ | 40 | 48.3 | 50 |

| 2″ | 50 | 60.3 | 58 |

| 2-1/2″ | 65 | 76.1 | 69 |

| 3″ | 80 | 88.9 | 78 |

| 4″ | 100 | 114.3 | 96 |

| 6″ | 150 | 165.1 | 131 |

NOTE:NSF 61 certificate is availiable for M0101 M0102,M0113

application

- Structural Plumbing: This is the specific term example of connecting different diameter vertical and horizontal pipes to achieve right angle turns, building plumbing systems.

- Gas- Distribution Networks: For safe transportation of gas, these connections are made in right angles, which connects the gas pipes with different diameters and located inside or outside the housing.

- Industrial Equipment Layouts: Small right angle connections for equipment interfaces like compressors, reactors

- Ship Pipe Optimization: Pipes with sharp angle and diameter changes in the confined engine rooms.

- HVAC – Main Chilled Water Pipe to Terminal Equipment with different diameters angle connections.

- Agricultural irrigation updates: pressure-resistant angle connections in main pipelines between pump stations and field branch pipelines—these are of various diameters.

advantages

- Dual-function integrated design: a single piece simultaneously achieves 90° pipe turning and diameter transition.

- Fluid dynamics optimization: smooth flow channel design minimizes pressure loss and turbulence.

- High-pressure sealing performance: reinforced structure ensures zero leakage operation under extreme pressure conditions.

- Corrosion Resistance in All Environments: Galvanized coating resists corrosion from humid environments and weak chemical media.

- Compact Space Adaptability: Right-angle structure saves installation space and improves pipeline layout efficiency.

- Wide Temperature Range Stability: Maintains material structure and seal integrity in extreme cold and high-temperature environments.

- Dual Standard Certification: Certified by international drinking water safety and fireproof/explosion-proof systems.

- Lifetime Maintenance-Free Commitment: Special processes significantly extend the service life of the pipeline system.

packing

- Curved Surface Protective Pad: Custom PE foam is applied to protect against collisions on 90° curved surfaces.

- Different Diameter End Protection: Dual-diameter protective covers are used to protect different thread specifications.

- Shockproof Full Coverage: Bubble column bags completely cover the surface of the elbow to prevent scratches.

- Intelligent Specification Positioning: Honeycomb cardboard partitions are used to fix items in place according to size and prevent displacement.

- Dual-color flow direction indicators: Outer boxes are printed with installation flow direction arrows and diameter change direction indicators.

- Load-bearing grading scheme: Small-sized paper boxes/large-sized reinforced wooden boxes are packed separately.

- Full-process traceability system: Laser engraving + smart QR code dual traceability management.

- Anti-rolling packing design: Concave groove structure inside the box ensures zero displacement during transportation.

Available size

| SIZE | A | ||

| INCH | DN | MM | MM |

| 1/4″ | 8 | 13.5 | 21 |

| 3/8″ | 10 | 17.2 | 25 |

| 1/2″ | 15 | 21.3 | 28 |

| 3/4″ | 20 | 26.9 | 33 |

| 1″ | 25 | 33.7 | 38 |

| 1-1/4″ | 32 | 42.4 | 45 |

| 1-1/2″ | 40 | 48.3 | 50 |

| 2″ | 50 | 60.3 | 58 |

| 2-1/2″ | 65 | 76.1 | 69 |

| 3″ | 80 | 88.9 | 78 |

| 4″ | 100 | 114.3 | 96 |

| 6″ | 150 | 165.1 | 131 |

NOTE:NSF 61 certificate is availiable for M0101 M0102,M0113

- Structural Plumbing: This is the specific term example of connecting different diameter vertical and horizontal pipes to achieve right angle turns, building plumbing systems.

- Gas- Distribution Networks: For safe transportation of gas, these connections are made in right angles, which connects the gas pipes with different diameters and located inside or outside the housing.

- Industrial Equipment Layouts: Small right angle connections for equipment interfaces like compressors, reactors

- Ship Pipe Optimization: Pipes with sharp angle and diameter changes in the confined engine rooms.

- HVAC – Main Chilled Water Pipe to Terminal Equipment with different diameters angle connections.

- Agricultural irrigation updates: pressure-resistant angle connections in main pipelines between pump stations and field branch pipelines—these are of various diameters.

- Dual-function integrated design: a single piece simultaneously achieves 90° pipe turning and diameter transition.

- Fluid dynamics optimization: smooth flow channel design minimizes pressure loss and turbulence.

- High-pressure sealing performance: reinforced structure ensures zero leakage operation under extreme pressure conditions.

- Corrosion Resistance in All Environments: Galvanized coating resists corrosion from humid environments and weak chemical media.

- Compact Space Adaptability: Right-angle structure saves installation space and improves pipeline layout efficiency.

- Wide Temperature Range Stability: Maintains material structure and seal integrity in extreme cold and high-temperature environments.

- Dual Standard Certification: Certified by international drinking water safety and fireproof/explosion-proof systems.

- Lifetime Maintenance-Free Commitment: Special processes significantly extend the service life of the pipeline system.

- Curved Surface Protective Pad: Custom PE foam is applied to protect against collisions on 90° curved surfaces.

- Different Diameter End Protection: Dual-diameter protective covers are used to protect different thread specifications.

- Shockproof Full Coverage: Bubble column bags completely cover the surface of the elbow to prevent scratches.

- Intelligent Specification Positioning: Honeycomb cardboard partitions are used to fix items in place according to size and prevent displacement.

- Dual-color flow direction indicators: Outer boxes are printed with installation flow direction arrows and diameter change direction indicators.

- Load-bearing grading scheme: Small-sized paper boxes/large-sized reinforced wooden boxes are packed separately.

- Full-process traceability system: Laser engraving + smart QR code dual traceability management.

- Anti-rolling packing design: Concave groove structure inside the box ensures zero displacement during transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.