HOT PRODUCTS TAGS

Malleable cast iron unequal tee (Reducing tee)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 3/4″ x 3/4″ x 1/2″-4″ x 4″ x 3″”

description

The malleable cast iron unequal tee (reducing tee) comes in various specifications, ensures tight connection, and efficiently transitions between pipes of different diameters.

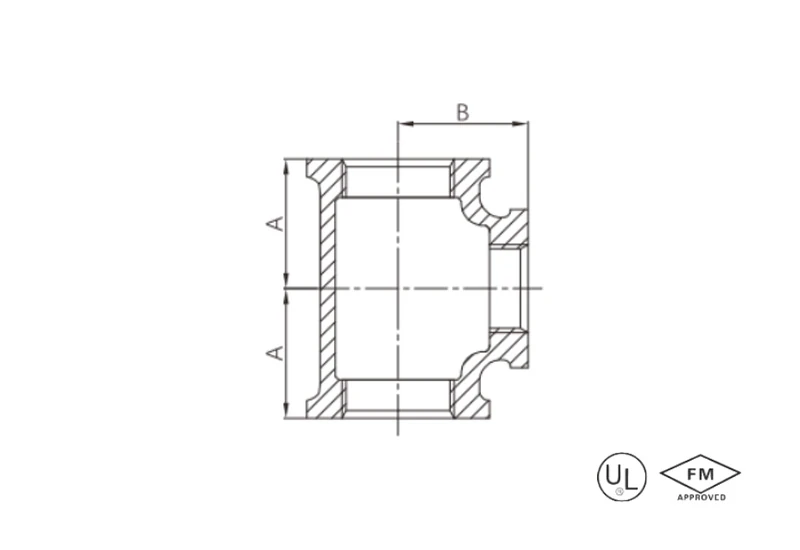

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

3/4″ x 3/4″ x 1/2″ | 20 x 20 x 15 | 26.9 x 26.9 x 21.3 | 30 | 31 |

1″ x 1″ x 3/8″ | 25 x 25 x 10 | 33.7 x 33.7 x 17.2 | 30 | 32 |

1″ x 1″ x 1/2″ | 25 x 25 x 15 | 33.7 x 33.7 x 21.3 | 32 | 34 |

1″ x 1″ x 3/4″ | 25 x 25 x 20 | 33.7 x 33.7 x 26.9 | 35 | 36 |

1-1/4″ x 1-1/4″ x 3/8″ | 32 x 32 x 10 | 42.4 x 42.4 x 17.2 | 32 | 36 |

1-1/4″ x 1-1/4″ x 1/2″ | 32 x 32 x 15 | 42.4 x 42.4 x 21.3 | 34 | 38 |

1-1/4″ x 1-1/4″ x 3/4″ | 32 x 32 x 20 | 42.4 x 42.4 x 26.9 | 36 | 41 |

1-1/4″ x 1-1/4″ x 1″ | 32 x 32 x 25 | 42.4 x 42.4 x 33.7 | 40 | 42 |

1-1/2″ x 1-1/2″ x 1/2″ | 40 x 40 x 15 | 48.3 x 48.3 x 21.3 | 36 | 42 |

1-1/2″ x 1-1/2″ x 3/4″ | 40 x 40 x 20 | 48.3 x 48.3 x 26.9 | 38 | 44 |

1-1/2″ x 1-1/2″ x 1″ | 40 x 40 x 25 | 48.3 x 48.3 x 33.7 | 42 | 46 |

1-1/2″ x 1-1/2″ x 1-1/4″ | 40 x 40 x 32 | 48.3 x 48.3 x 42.4 | 46 | 48 |

2″ x 2″ x 1/2″ | 50 x 50 x 15 | 60.3 x 60.3 x 21.3 | 38 | 48 |

2″ x 2″ x 3/4″ | 50 x 50 x 20 | 60.3 x 60.3 x 26.9 | 40 | 50 |

2″ x 2″ x 1″ | 50 x 50 x 25 | 60.3 x 60.3 x 33.7 | 44 | 52 |

2″ x 2″ x 1-1/4″ | 50 x 50 x 32 | 60.3 x 60.3 x 42.4 | 48 | 54 |

2″ x 2″ x 1-1/2″ | 50 x 50 x 40 | 60.3 x 60.3 x 48.3 | 52 | 55 |

2-1/2″ x 2-1/2″ x 1/2″ | 65 x 65 x 15 | 76.1 x 76.1 x 21.3 | 40 | 56 |

2-1/2″ x 2-1/2″ x 3/4″ | 65 x 65 x 20 | 76.1 x 76.1 x 26.9 | 43 | 57 |

2-1/2″ x 2-1/2″ x 1″ | 65 x 65 x 25 | 76.1 x 76.1 x 33.7 | 47 | 60 |

2-1/2″ x 2-1/2″ x 1-1/4″ | 65 x 65 x 32 | 76.1 x 76.1 x 42.4 | 52 | 62 |

2-1/2″ x 2-1/2″ x 1-1/2″ | 65 x 65 x 40 | 76.1 x 76.1 x 48.3 | 55 | 63 |

2-1/2″ x 2-1/2″ x 2″ | 65 x 65 x 50 | 76.1 x 76.1 x 60.3 | 61 | 66 |

3″ x 3″ x 1/2″ | 80 x 80 x 15 | 88.9 x 88.9 x 21.3 | 42 | 64 |

3″ x 3″ x 3/4″ | 80 x 80 x 20 | 88.9 x 88.9 x 26.9 | 45 | 65 |

3″ x 3″ x 1″ | 80 x 80 x 25 | 88.9 x 88.9 x 33.7 | 51 | 67 |

3″ x 3″ x 1-1/4″ | 80 x 80 x 32 | 88.9 x 88.9 x 42.4 | 55 | 70 |

3″ x 3″ x 1-1/2″ | 80 x 80 x 40 | 88.9 x 88.9 x 48.3 | 58 | 71 |

3″ x 3″ x 2″ | 80 x 80 x 50 | 88.9 x 88.9 x 60.3 | 64 | 73 |

3″ x 3″ x 2-1/2″ | 80 x 80 x 65 | 88.9 x 88.9 x 76.1 | 72 | 76 |

4″ x 4″ x 1/2″ | 100 x 100 x 15 | 114.3 x 114.3 x 21.3 | 50 | 79 |

4″ x 4″ x 3/4″ | 100 x 100 x 20 | 114.3 x 114.3 x 26.9 | 53 | 79 |

4″ x 4″ x 1″ | 100 x 100 x 25 | 114.3 x 114.3 x 33.7 | 56 | 81 |

4″ x 4″ x 1-1/4″ | 100 x 100 x 32 | 114.3 x 114.3 x 42.4 | 60 | 84 |

4″ x 4″ x 1-1/2″ | 100 x 100 x 40 | 114.3 x 114.3 x 48.3 | 61 | 84 |

4″ x 4″ x 2″ | 100 x 100 x 50 | 114.3 x 114.3 x 60.3 | 70 | 86 |

4″ x 4″ x 2-1/2″ | 100 x 100 x 65 | 114.3 x 114.3 x 76.1 | 84 | 92 |

4″ x 4″ x 3″ | 100 x 100 x 80 | 114.3 x 114.3 x 88.9 | 82 | 90 |

Note: NSF 61 certificate is available for M1010 ~ M1053, except M1015.

application

- Building Plumbing Systems: Main pipelines with bidirectional equal-diameter branching for balanced water supply.

- Fire Protection Network Layout: UL/FM certification ensures multi-directional equal-pressure branching for sprinkler systems.

- HVAC Engineering: Main chilled water pipelines with equal-diameter three-way branching for distribution.

- Industrial Fluid Networks: Chemical pipelines with equal-pressure multi-directional medium distribution.

- Ship Power Systems: Equal-diameter fuel/coolant three-way branching within engine room spaces.

- Agricultural Irrigation Hub: Main pipeline of the pump station with equal-pressure branch pipes for synchronized irrigation.

- Energy Transmission Network: Equal-diameter three-way branching at inspection ports of oil and gas pipelines.

- Municipal Pipeline Network Nodes: Equal-pressure branching at maintenance interfaces on the main water supply pipeline.

advantages

- Three-way equal pressure design: Precise flow distribution ensures balanced pressure across all branches.

- High-pressure sealing structure: Triple zero-leakage sealing with BSPT tapered threads under 25 bar conditions.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists chemical media/salt spray corrosion.

- Enhanced fluid performance: Smooth inner wall channels reduce vortex resistance by 20%.

- Dual international certifications: UL/FM fire safety certification and NSF 61 certification (applicable to M0901/M0902/M0913 models).

- Water hammer resistance: Ductile iron base absorbs pressure fluctuation peaks.

- Wide temperature range stability: Maintains structural integrity from -30°C to 120°C.

- Lifetime maintenance-free guarantee: Special processes extend the service life of the piping system.

packing

- Three-port three-dimensional protection: custom injection molded cover nests three threaded ports.

- Node buffer system: EPE pearl cotton molded wrap tee body shockproof.

- Full surface armor treatment: vapor phase anti-rust film + winding bubble column sealing.

- Intelligent positioning and packing: laser-cut foam board accurately triangular card position according to size.

- Diversion Identification System: Three-way fluid red indicator arrow printed on the outer box.

- Load-bearing classification scheme: ≤1.5″ with five-layer corrugated box / ≥2″ with steel strip wooden box.

- Special certification management: NSF certified models are independently labeled and test reports are attached.

- Anti-displacement structure: Triangular bracket in the box fixed tee zero displacement transportation.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

3/4″ x 3/4″ x 1/2″ | 20 x 20 x 15 | 26.9 x 26.9 x 21.3 | 30 | 31 |

1″ x 1″ x 3/8″ | 25 x 25 x 10 | 33.7 x 33.7 x 17.2 | 30 | 32 |

1″ x 1″ x 1/2″ | 25 x 25 x 15 | 33.7 x 33.7 x 21.3 | 32 | 34 |

1″ x 1″ x 3/4″ | 25 x 25 x 20 | 33.7 x 33.7 x 26.9 | 35 | 36 |

1-1/4″ x 1-1/4″ x 3/8″ | 32 x 32 x 10 | 42.4 x 42.4 x 17.2 | 32 | 36 |

1-1/4″ x 1-1/4″ x 1/2″ | 32 x 32 x 15 | 42.4 x 42.4 x 21.3 | 34 | 38 |

1-1/4″ x 1-1/4″ x 3/4″ | 32 x 32 x 20 | 42.4 x 42.4 x 26.9 | 36 | 41 |

1-1/4″ x 1-1/4″ x 1″ | 32 x 32 x 25 | 42.4 x 42.4 x 33.7 | 40 | 42 |

1-1/2″ x 1-1/2″ x 1/2″ | 40 x 40 x 15 | 48.3 x 48.3 x 21.3 | 36 | 42 |

1-1/2″ x 1-1/2″ x 3/4″ | 40 x 40 x 20 | 48.3 x 48.3 x 26.9 | 38 | 44 |

1-1/2″ x 1-1/2″ x 1″ | 40 x 40 x 25 | 48.3 x 48.3 x 33.7 | 42 | 46 |

1-1/2″ x 1-1/2″ x 1-1/4″ | 40 x 40 x 32 | 48.3 x 48.3 x 42.4 | 46 | 48 |

2″ x 2″ x 1/2″ | 50 x 50 x 15 | 60.3 x 60.3 x 21.3 | 38 | 48 |

2″ x 2″ x 3/4″ | 50 x 50 x 20 | 60.3 x 60.3 x 26.9 | 40 | 50 |

2″ x 2″ x 1″ | 50 x 50 x 25 | 60.3 x 60.3 x 33.7 | 44 | 52 |

2″ x 2″ x 1-1/4″ | 50 x 50 x 32 | 60.3 x 60.3 x 42.4 | 48 | 54 |

2″ x 2″ x 1-1/2″ | 50 x 50 x 40 | 60.3 x 60.3 x 48.3 | 52 | 55 |

2-1/2″ x 2-1/2″ x 1/2″ | 65 x 65 x 15 | 76.1 x 76.1 x 21.3 | 40 | 56 |

2-1/2″ x 2-1/2″ x 3/4″ | 65 x 65 x 20 | 76.1 x 76.1 x 26.9 | 43 | 57 |

2-1/2″ x 2-1/2″ x 1″ | 65 x 65 x 25 | 76.1 x 76.1 x 33.7 | 47 | 60 |

2-1/2″ x 2-1/2″ x 1-1/4″ | 65 x 65 x 32 | 76.1 x 76.1 x 42.4 | 52 | 62 |

2-1/2″ x 2-1/2″ x 1-1/2″ | 65 x 65 x 40 | 76.1 x 76.1 x 48.3 | 55 | 63 |

2-1/2″ x 2-1/2″ x 2″ | 65 x 65 x 50 | 76.1 x 76.1 x 60.3 | 61 | 66 |

3″ x 3″ x 1/2″ | 80 x 80 x 15 | 88.9 x 88.9 x 21.3 | 42 | 64 |

3″ x 3″ x 3/4″ | 80 x 80 x 20 | 88.9 x 88.9 x 26.9 | 45 | 65 |

3″ x 3″ x 1″ | 80 x 80 x 25 | 88.9 x 88.9 x 33.7 | 51 | 67 |

3″ x 3″ x 1-1/4″ | 80 x 80 x 32 | 88.9 x 88.9 x 42.4 | 55 | 70 |

3″ x 3″ x 1-1/2″ | 80 x 80 x 40 | 88.9 x 88.9 x 48.3 | 58 | 71 |

3″ x 3″ x 2″ | 80 x 80 x 50 | 88.9 x 88.9 x 60.3 | 64 | 73 |

3″ x 3″ x 2-1/2″ | 80 x 80 x 65 | 88.9 x 88.9 x 76.1 | 72 | 76 |

4″ x 4″ x 1/2″ | 100 x 100 x 15 | 114.3 x 114.3 x 21.3 | 50 | 79 |

4″ x 4″ x 3/4″ | 100 x 100 x 20 | 114.3 x 114.3 x 26.9 | 53 | 79 |

4″ x 4″ x 1″ | 100 x 100 x 25 | 114.3 x 114.3 x 33.7 | 56 | 81 |

4″ x 4″ x 1-1/4″ | 100 x 100 x 32 | 114.3 x 114.3 x 42.4 | 60 | 84 |

4″ x 4″ x 1-1/2″ | 100 x 100 x 40 | 114.3 x 114.3 x 48.3 | 61 | 84 |

4″ x 4″ x 2″ | 100 x 100 x 50 | 114.3 x 114.3 x 60.3 | 70 | 86 |

4″ x 4″ x 2-1/2″ | 100 x 100 x 65 | 114.3 x 114.3 x 76.1 | 84 | 92 |

4″ x 4″ x 3″ | 100 x 100 x 80 | 114.3 x 114.3 x 88.9 | 82 | 90 |

Note: NSF 61 certificate is available for M1010 ~ M1053, except M1015.

- Building Plumbing Systems: Main pipelines with bidirectional equal-diameter branching for balanced water supply.

- Fire Protection Network Layout: UL/FM certification ensures multi-directional equal-pressure branching for sprinkler systems.

- HVAC Engineering: Main chilled water pipelines with equal-diameter three-way branching for distribution.

- Industrial Fluid Networks: Chemical pipelines with equal-pressure multi-directional medium distribution.

- Ship Power Systems: Equal-diameter fuel/coolant three-way branching within engine room spaces.

- Agricultural Irrigation Hub: Main pipeline of the pump station with equal-pressure branch pipes for synchronized irrigation.

- Energy Transmission Network: Equal-diameter three-way branching at inspection ports of oil and gas pipelines.

- Municipal Pipeline Network Nodes: Equal-pressure branching at maintenance interfaces on the main water supply pipeline.

- Three-way equal pressure design: Precise flow distribution ensures balanced pressure across all branches.

- High-pressure sealing structure: Triple zero-leakage sealing with BSPT tapered threads under 25 bar conditions.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists chemical media/salt spray corrosion.

- Enhanced fluid performance: Smooth inner wall channels reduce vortex resistance by 20%.

- Dual international certifications: UL/FM fire safety certification and NSF 61 certification (applicable to M0901/M0902/M0913 models).

- Water hammer resistance: Ductile iron base absorbs pressure fluctuation peaks.

- Wide temperature range stability: Maintains structural integrity from -30°C to 120°C.

- Lifetime maintenance-free guarantee: Special processes extend the service life of the piping system.

- Three-port three-dimensional protection: custom injection molded cover nests three threaded ports.

- Node buffer system: EPE pearl cotton molded wrap tee body shockproof.

- Full surface armor treatment: vapor phase anti-rust film + winding bubble column sealing.

- Intelligent positioning and packing: laser-cut foam board accurately triangular card position according to size.

- Diversion Identification System: Three-way fluid red indicator arrow printed on the outer box.

- Load-bearing classification scheme: ≤1.5″ with five-layer corrugated box / ≥2″ with steel strip wooden box.

- Special certification management: NSF certified models are independently labeled and test reports are attached.

- Anti-displacement structure: Triangular bracket in the box fixed tee zero displacement transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.