HOT PRODUCTS TAGS

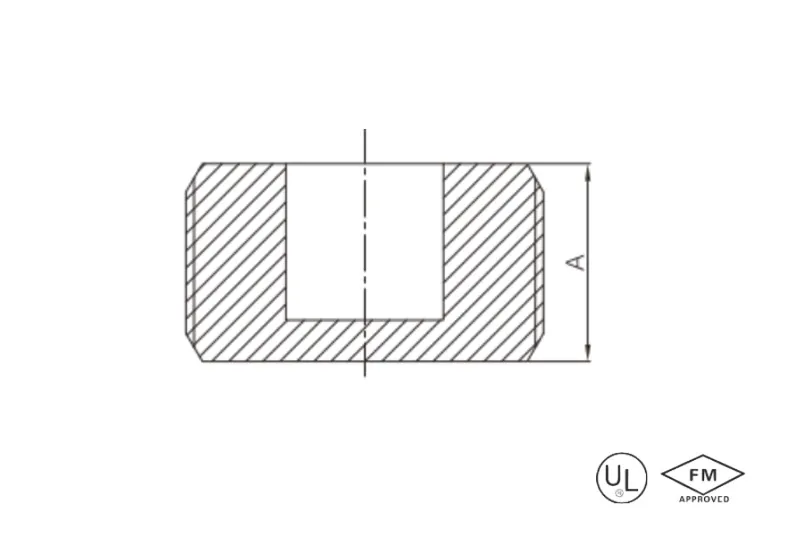

Malleable cast iron countersunk plug

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —3″

description

Malleable cast iron countersunk plug, countersunk design for flush embedding, tight sealing, wear-resistant and pressure-resistant, suitable for various pipelines.

Specification

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 15 |

3/4″ | 20 | 26.9 | 16 |

1″ | 25 | 33.7 | 19 |

1-1/4″ | 32 | 42.4 | 20 |

1-1/2″ | 40 | 48.3 | 21 |

2″ | 50 | 60.3 | 22 |

2-1/2″ | 65 | 76.1 | 27 |

3″ | 80 | 88.9 | 39 |

Note: NSF 61 certificate is available for M3603 ~ M3610.

application

- Precision Equipment Pipe Sealing: Countersunk design meets the flush sealing requirements of mechanical equipment pipes.

- Fire Protection System Terminal Protection: Embedded anti-collision sealing solution for sprinkler network terminals.

- Compact Ship Engine Room Space: Flush safety sealing for fuel/cooling water pipe terminals.

- Industrial Instrument Interface Management: Embedded protection solution for process instrument reserve ports.

- Municipal pipeline renovation projects: Scratch-resistant sealing components for pipeline terminals under sidewalks.

- Energy transmission system protection: Sealing solutions for oil and gas pipeline ground interfaces to prevent external force damage.

- Chemical plant maintenance: Flush chemical-resistant sealing for pipeline terminals in corrosive environments.

- Mining equipment pipelines: Embedded terminal sealing solutions to prevent loosening in high-vibration conditions.

advantages

- Integrated sealing design: The end of the pipe can be closed flush with the counterbore.

- Anti-collision optimization: Flush mounted installation, reduce the risk of external mechanical damage.

- Surface wear-resistant treatment: The special polishing process is long-lasting and the seal is still tight.

- Rust protection: comprehensive corrosion protection by means of hot-dip galvanized coatingurator-barrier and cathode electronagesis system for a long time.

- Streamlined design: 50% less than the size of conventional pipe plugs.

- Safety compliance confidence: Certain models meet requirements for contact with drinking water .

packing

- End Face Precision Protection: Custom PE cushioning modules fitted to countersunk curved surfaces.

- Thread Protection Solution: Engineering plastic screw cap nested protection thread structure.

- Anti-rust Treatment Process: Vapor phase anti-rust film (VCI) vacuum sealed packaging.

- Anti-error Positioning Architecture: Laser-cut EVA inner lining countersunk dedicated card slot.

- Unitized Transportation Solution: High-strength corrugated boxes with layered positioning packaging.

- Traceability Information Integration: Box QR codes linked to certification and specification parameters.

- Surface Protection Design: Scratch-resistant film covering countersunk sealed end faces.

Available size

SIZE | A(min) | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 15 |

3/4″ | 20 | 26.9 | 16 |

1″ | 25 | 33.7 | 19 |

1-1/4″ | 32 | 42.4 | 20 |

1-1/2″ | 40 | 48.3 | 21 |

2″ | 50 | 60.3 | 22 |

2-1/2″ | 65 | 76.1 | 27 |

3″ | 80 | 88.9 | 39 |

Note: NSF 61 certificate is available for M3603 ~ M3610.

- Precision Equipment Pipe Sealing: Countersunk design meets the flush sealing requirements of mechanical equipment pipes.

- Fire Protection System Terminal Protection: Embedded anti-collision sealing solution for sprinkler network terminals.

- Compact Ship Engine Room Space: Flush safety sealing for fuel/cooling water pipe terminals.

- Industrial Instrument Interface Management: Embedded protection solution for process instrument reserve ports.

- Municipal pipeline renovation projects: Scratch-resistant sealing components for pipeline terminals under sidewalks.

- Energy transmission system protection: Sealing solutions for oil and gas pipeline ground interfaces to prevent external force damage.

- Chemical plant maintenance: Flush chemical-resistant sealing for pipeline terminals in corrosive environments.

- Mining equipment pipelines: Embedded terminal sealing solutions to prevent loosening in high-vibration conditions.

- Integrated sealing design: The end of the pipe can be closed flush with the counterbore.

- Anti-collision optimization: Flush mounted installation, reduce the risk of external mechanical damage.

- Surface wear-resistant treatment: The special polishing process is long-lasting and the seal is still tight.

- Rust protection: comprehensive corrosion protection by means of hot-dip galvanized coatingurator-barrier and cathode electronagesis system for a long time.

- Streamlined design: 50% less than the size of conventional pipe plugs.

- Safety compliance confidence: Certain models meet requirements for contact with drinking water .

- End Face Precision Protection: Custom PE cushioning modules fitted to countersunk curved surfaces.

- Thread Protection Solution: Engineering plastic screw cap nested protection thread structure.

- Anti-rust Treatment Process: Vapor phase anti-rust film (VCI) vacuum sealed packaging.

- Anti-error Positioning Architecture: Laser-cut EVA inner lining countersunk dedicated card slot.

- Unitized Transportation Solution: High-strength corrugated boxes with layered positioning packaging.

- Traceability Information Integration: Box QR codes linked to certification and specification parameters.

- Surface Protection Design: Scratch-resistant film covering countersunk sealed end faces.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.