الفرق بين أنابيب A671 و A672 EFW

مقدمة

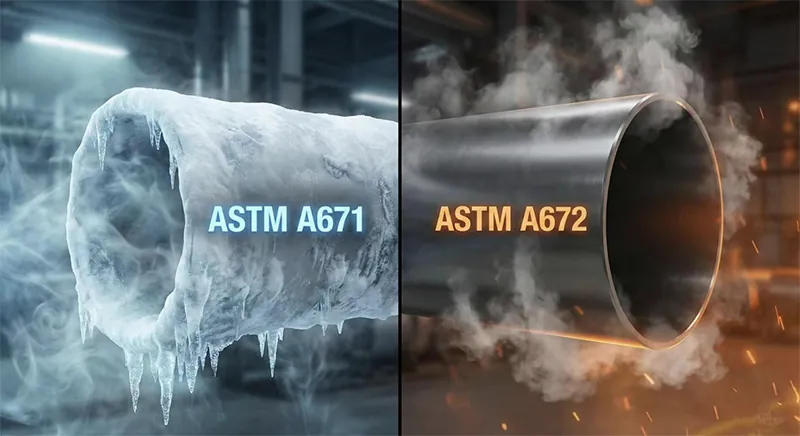

بالنسبة لتطبيقات الأنابيب الصناعية ذات القطر الكبير، فإن المعيارين الأكثر شيوعًا للأنابيب الملحومة بالانصهار الكهربائي (EFW) هما ASTM A671 و ASTM A672، ومع ذلك فإن اصطلاحات التسمية الشائعة - أي استخدام نفس المصطلحات مثل “الدرجة” و“الفئة”) تؤدي إلى الكثير من الارتباك للمهندسين والمشترين، وعلى الرغم من أن هذين المعيارين لهما أوجه تشابه كبيرة في عمليات التشكيل ويبدوان متشابهين للغاية، إلا أنهما يخدمان مقاصد هندسية مختلفة للغاية: صُممت إحداهما لمكافحة الهشاشة في ظروف درجات الحرارة المنخفضة المبردة أو المنخفضة للغاية، والأخرى مصممة لتحمل الضغط العالي للغاية في درجات الحرارة المعتدلة، مما يعني أن استخدام المواصفات الخاطئة يمكن أن يؤدي إلى فشل كارثي لخط الأنابيب.هذه المقالة هي محطتك الوحيدة للحصول على شرح فني (درجة حرارة التطبيق، واختيار اللوحة الأصلية، والمعالجة الحرارية ومتطلبات الاختبار) للتمييز بين ASTM A671 مقابل A672 ولكي تقوم بالاختيار الهندسي الصحيح للبنية التحتية الحيوية لديك.

درجة حرارة الخدمة

ستعطيك مقارنة عنواني مواصفات A671 و A672 فكرة عن الاختلافات. الاختلافات ليست غامضة - بل تحددها بيئة التشغيل بشكل واضح.

ASTM A671 (المتخصص في درجات الحرارة المنخفضة)

- العنوان الكامل.المواصفة القياسية لأنابيب الصلب EFW لأنابيب الصلب EFW لدرجات الحرارة الجوية ودرجات الحرارة المنخفضة.

- السياق الهندسي: هذه المواصفة مناسبة للاستخدام عندما يتعرض الأنبوب للخدمة الباردة. كلما انخفضت درجة الحرارة، يصبح الفولاذ هشًا بطبيعته (الانتقال من الدكتايل إلى الهشاشة). تم تصميم أنابيب الصلب EFW المطابقة للمواصفة A671 خصيصًا واختبارها للاحتفاظ بصلابتها وتجنب التكسير في درجات الحرارة من درجة الحرارة المحيطة إلى المبردة.

- التطبيقات النموذجية: نقل الغاز المسال (أنابيب غاز البترول المسال/الغاز الطبيعي المسال)، وأوعية الضغط المبردة، والأنابيب في المناخات القطبية أو دون الصفر.

ASTM A672 (المتخصص في درجات الحرارة المعتدلة)

- العنوان الكامل: المواصفة القياسية لأنابيب الصلب EFW للخدمة تحت الضغط العالي في درجات حرارة معتدلة.

- السياق الهندسي: تختص هذه المواصفة بمتطلبات الاحتفاظ بالضغط والثبات الهيكلي في الحرارة “المعتدلة”. وهي غير مخصصة للبرودة الشديدة، ولا لدرجات حرارة نطاق الزحف القصوى التي تغطيها المواصفة ASTM A691 (درجة الحرارة العالية).

- التطبيقات النموذجية: خطوط الإمداد بالبخار، وخطوط إمداد البخار، وخطوط المواد الأولية في المصافي، ونقل السوائل عالية الضغط بشكل عام حيث لا يمثل التجميد مصدر قلق.

الخلاصة: درجة الحرارة هي مرشحك الأول. حيثما تكون درجة حرارة التصميم أقل من 0 درجة مئوية (-32 درجة فهرنهايت) ستحتاج إلى A671. أما إذا كان التصميم للضغط العالي في درجة حرارة محيطة أو متوسطة (حتى حوالي 400 درجة مئوية أو 750 درجة فهرنهايت)، فإن المعيار هو A672.

الصف: اللوحة الأم

على عكس الأنابيب غير الملحومة التي يتم تعريفها من خلال تركيبها الكيميائي على أنها “أنبوب” (على سبيل المثال، A106)، يتم تصنيع أنابيب EFW منألواح الصلب. ولذلك، فإن “درجة” الأنبوب A671 أو A672 تشير في الواقع إلى مواصفات الصفيحة الفولاذية الخام المستخدمة في تشكيله.

درجات ASTM A671 (التركيز على المتانة)

يتم اختيار الدرجات في A671 لخصائصها في درجات الحرارة المنخفضة الصدمية.

- الصف المشترك: CC60، CC70.

- اللوحة الأم: تتوافق هذه عادةً مع ASTM A516 (ألواح أوعية الضغط، الصلب الكربوني، للخدمة في درجات الحرارة المتوسطة والمنخفضة).

- المعادن: صُنعت صفيحة ASTM A516 من صفيحة ASTM A516 ذات حجم حبيبات أوستنيتي دقيق. هذه البنية الحبيبية الدقيقة ضرورية للحفاظ على صلابة الشق (مقاومة التشقق) في درجات الحرارة المنخفضة.

درجات ASTM A672 (التركيز على المتانة)

يتم اختيار الدرجات في A672 من أجل قوة الشد والاحتفاظ بالضغط.

- الصف المشترك: B60، C70.

- اللوحة الأم:

- الدرجات أ، ب، ج غالبًا ما تتوافق مع ASTM A285 (ألواح أوعية الضغط، الفولاذ الكربوني، منخفضة ومتوسطة الشد).

- الصفوف J، K، L غالبًا ما تتوافق معASTM A516.

- المعادن: في حين يمكن أن تستخدم A672 نفس صفيحة A516 مثل A671، يمكن أيضًا استخدام ألواح الفولاذ الكربوني الأبسط مثل A285 إذا لم تكن الصلابة في درجات الحرارة المنخفضة مطلوبة.

جدول المقارنة: مواصفات درجة الأنبوب مقابل مواصفات اللوحة الأصلية

| مواصفات الأنابيب | تعيين درجة الأنابيب | مواصفات لوحة ASTM المقابلة | الخاصية الأساسية |

| ASTM A671 | الصف CA 55 | ASTM A285 Gr. C | كربون عادي |

| الصف CC 60 | ASTM A516 Gr. 60 | الحبيبات الدقيقة (درجة حرارة منخفضة) | |

| الصف CC 70 | ASTM A516 Gr. 70 | الحبيبات الدقيقة (درجة حرارة منخفضة) | |

| ASTM A672 | الصف أ 45 | ASTM A285 Gr. A | الشد المنخفض |

| الدرجة ب 60 | ASTM A516 Gr. 60 | درجة حرارة معتدلة/ضغط مرتفع | |

| الدرجة C 70 | ASTM A516 Gr. 70 | درجة حرارة معتدلة/ضغط مرتفع |

(ملاحظة: A671 CC60 مقابل A672 C70 A671 C60 هي مقارنة شائعة. وعلى الرغم من أن كلاهما قد يستخدم اللوح A516، إلا أن متطلبات الاختبار المفروضة على هذا اللوح تختلف بناءً على مواصفات الأنبوب).

جودة اللحام و NDT

ولعل الجانب الأكثر إرباكًا في هذه المعايير هو نظام “الفئة” (على سبيل المثال، CL12، CL22، CL32). لا تشير الفئة إلى قوة الفولاذ؛ فهي تشير إلى المعالجة الحرارية لما بعد اللحام (PWHT) ومدى الاختبارات غير المدمرة (NDT) التي أجريت على خط اللحام.

هذا هو المكان الذي تكون فيه القدرة التصنيعية لـ ألاند تصبح حرجة. كمنتج لـ أنابيب LSAW بالنسبة لأوعية الضغط، يجب أن نلتزم بدقة بتسميات هذه الفئات لضمان أن يكون خط اللحام قويًا مثل جسم الأنبوب.

عادةً ما تكون تسمية الفئة عبارة عن رقم مكون من رقمين (على سبيل المثال.CL 22):

1. الرقم الأول يشير إلى المعالجة الحرارية.

2. الرقم الثاني يشير إلى متطلبات التصوير الإشعاعي (الأشعة السينية).

رموز المعالجة الحرارية (الرقم الأول)

- 10-19: لا يتطلب معالجة حرارية (كما هو ملحوم).

- 20-29: تخفيف الإجهاد (المعالجة الحرارية لما بعد اللحام - PWHT). يقلل ذلك من الضغوط الداخلية المتبقية الناتجة عن عملية اللحام.

- 30-39: تطبيع. يتم تسخين الأنبوب بأكمله إلى نطاق يتم فيه إعادة بلورة بنية الحبيبات مما يوفر أعلى مستوى من التوحيد.

رموز التصوير الإشعاعي (الرقم الثاني)

- 0: لا يوجد تصوير إشعاعي.

- 1: التصوير الإشعاعي الموضعي (اختبار العينة).

- 2:100% التصوير الشعاعي. (يتم تصوير كل بوصة من خط اللحام بالأشعة السينية).

- 3: 100% التصوير بالأشعة + الاختبار بالموجات فوق الصوتية (UT).

شرح الفئات الشائعة

- الفئة 12: بدون معالجة حرارية + 100% تصوير إشعاعي.

- الفئة 22 (معيار الصناعة): التصوير الإشعاعي من الدرجة 22 (معيار الصناعة): مخفف الإجهاد + 100%. هذه هي المواصفات الأكثر شيوعًا لأنابيب الضغط العالي لأنها تضمن خلو اللحام من الإجهاد وثبتت خلوه من العيوب ماديًا.

- الفئة 32: تصوير إشعاعي عادي + 100%. يُستخدم عند الحاجة إلى أقصى قدر من التوحيد البنيوي المجهري.

ميزة آلاند يتطلب تصنيع أنابيب EFW إلى الفئة 22 أو الفئة 32 قدرات داخلية متقدمة. ألاند مجهز بأفران معالجة حرارية واسعة النطاق واختبارات التصوير الإشعاعي الآلي لأنظمة أنابيب EFW، مما يضمن قدرتنا على تقديم أنابيب عالية الجودة تلبي أكثر قوانين أوعية الضغط صرامة (ASME BPVC).

اختبار التصادم (عامل الأمان)

يكمن الاختلاف النهائي والنهائي بين مواصفات ASTM A671 والمواصفة A672 في بروتوكولات الاختبار الإلزامية المتعلقة بالصلابة.

ASTM A671: درجة تشاربي V-Notch الإلزامية

نظرًا لأن A671 مصمم من أجل “درجات الحرارة المنخفضة”، فإن المعيار التفويضات أنه يجب أن يجتاز اللحام والمنطقة المتأثرة بالحرارة (HAZ) اختبار الصدم Charpy V-Notch (CVN).

- الغرض: لتحديد كمية الطاقة التي يمكن أن تمتصها المادة قبل أن تتكسر في درجات حرارة منخفضة.

- المتطلبات: إذا كنت تطلب A671 درجة CC60، فإن الشركة المصنعة يجب إثبات بقاء الأنبوب قابل للسحب عند درجة الحرارة المنخفضة المحددة (على سبيل المثال، -40 درجة مئوية أو -50 درجة فهرنهايت).

ASTM A672: الصلابة الاختيارية

نظرًا لأن A672 مخصص “لدرجات الحرارة المعتدلة”، فإن الكسر الهش أقل إثارة للقلق.

- الحالة: اختبار التأثير بشكل عام غير إلزامي ما لم تطلب الجهة المشترية تحديدًا في المتطلبات التكميلية (S2).

- التركيز: يتم التركيز في اختبار A672 على اختبارات قوة الشد (الشد المستعرض للحام) واختبارات الانحناء الموجه لضمان قدرة اللحام على تحمل الضغط العالي دون انفصال.

نظرة ثاقبة على المشتريات: إذا كنت تعمل في مناخ بارد ولكنك تحدد أنبوب A672 دون إضافة متطلبات اختبار الصدم التكميلي، فأنت تخاطر بشكل كبير. وعلى العكس من ذلك، قد يؤدي تحديد A671 لخط بخار ساخن إلى تكبد تكاليف اختبار غير ضرورية.

الخاتمة

إن الاختلاف بين ASTM A671 و ASTM A672 ليس مجرد اختلاف بيروقراطي، بل هو مسألة ديناميكا حرارية يجب على كل مهندس مواجهتها. إنها مسألة ديناميكا حرارية يجب أن يواجهها كل مهندس. يعتمد القرار فقط على ظروف الخدمة الخاصة بك: استخدم ASTM A671 للتطبيقات في درجات حرارة منخفضة لتجنب الكسر الهش، واستخدم ASTM A672 للخدمات في درجات حرارة منخفضة نسبيًا مع ضغط مرتفع. لا يجب الخلط بينهما؛ فقد يؤثر ذلك على أمان وعاء الضغط أو نظام الأنابيب الخاص بك.

وباعتبارها من كبار المصنعين، تمتلك شركة Allland خطوط إنتاج متطورة من LSAW وSSAW، بالإضافة إلى مرافق المعالجة الحرارية المتكاملة ومرافق NDT لمعالجة أنابيب EFW وفقًا لكلا المعيارين. سواء كنت تبحث عن صلابة A671 CC60 CL22 في درجات الحرارة المنخفضة أو ثبات الضغط العالي في A672 C70 CL32، يمكننا توفيرها. تواصل مع شركة Allland اليوم للتحدث عن متطلباتك الفردية لتطبيقات الأنابيب الملحومة EF والحصول على عرض أسعار فعال من حيث التكلفة ومتوافق مع المعايير.

احصل على عرض أسعار أنابيب الصلب المخصصة اليوم!

زوّدنا بتفاصيل مشروعك (مثل التطبيق والمواصفات والكمية). سيقدم لك فريقنا المتمرس حلاً مخصصاً وعرض أسعار تنافسي في غضون 24 ساعة عمل.