علامات المنتجات الساخنة

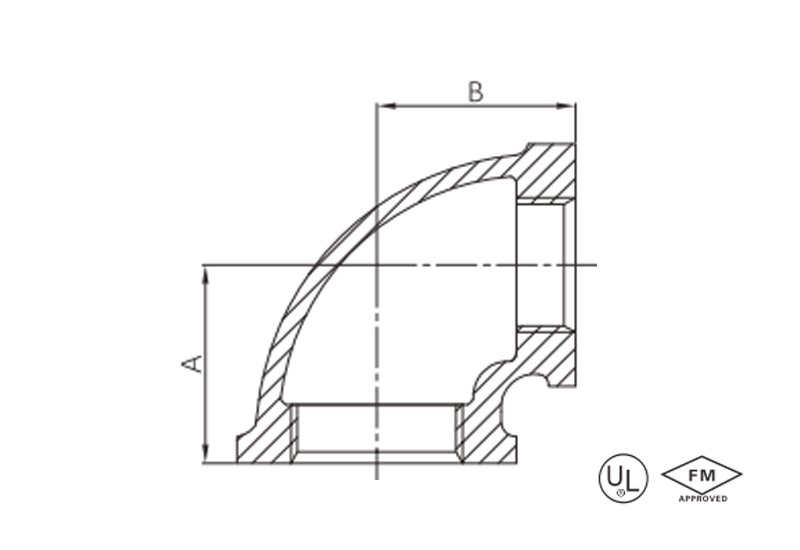

كوع مختزل 90 درجة من الحديد المطاوع بزاوية 90 درجة

-معيار: ANSI/ASME B16.3

UL/FM

-المواد: الحديد القابل للطرق ASTM A197

-الخيط: NPT

-الضغط: الفئة 150، 300 رطل لكل بوصة مربعة (-29 درجة مئوية إلى 66 درجة مئوية)

الفئة 300، 1000 / 1500 / 2000 رطل لكل بوصة مربعة

(من -29 درجة مئوية إلى 66 درجة مئوية)

-السطح: حديد أسود/مغلفن بالغمس الساخن

-نطاق الحجم: 1/2 بوصة × 3/8 بوصة × 4 بوصة × 3 بوصة (الفئة 150)

1/2 بوصة × 3/8 بوصة -1/1-1/4 بوصة × 1/2 بوصة (الفئة 300)

الوصف

كوع تخفيض 90 درجة من الحديد القابل للطرق بزاوية 90 درجة، مقاوم للضغط والتآكل، مناسب لمختلف خطوط الأنابيب، سهل التركيب، مع أداء ممتاز.

المواصفات

الحجم المتاح

الحجم | A | B | ||

بوصة | دن | مم | مم | مم |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 26.4 | 26.2 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 28.5 | 28.7 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 30.5 | 31 |

1″ x 1/4″ | 25 x 8 | 33.4 x 13.7 | 27 | 31 |

1″ x 3/8″ | 25 x 10 | 33.4 x 17.1 | 30 | 32.3 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 32 | 35.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 34.8 | 36.8 |

1-1/4″ x 3/8″ | 32 x 10 | 42.2 x 17.1 | 32 | 36.5 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 34 | 38.9 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 36.8 | 41.2 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 40.1 | 42.4 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 35 | 41.5 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 38.6 | 44.5 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 41.9 | 45.7 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 37.5 | 47.5 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 40.6 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 43.9 | 51.3 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 48.3 | 53.3 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 51.3 | 54.9 |

2-1/2″ x 3/4″ | 65 x 20 | 73.0 x 26.7 | 42 | 57 |

2-1/2″ x 1″ | 65 x 25 | 73.0 x 33.4 | 46 | 58.7 |

2-1/2″ x 1-1/4″ | 65 x 32 | 73.0 x 42.2 | 50.5 | 60 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 54.9 | 63.8 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 60.7 | 66 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.7 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.4 | 50 | 67.5 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.2 | 55 | 70 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 58 | 72 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73.4 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 71.9 | 75.9 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.2 | 60 | 85 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 62 | 85 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 69 | 87 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 73.0 | 78 | 90 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 83.8 | 91.4 |

1/2″x 3/8″ | 15 x 10 | 21.3 x 17.1 | 30.2 | 30.2 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 38.1 | 39.6 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 36.5 | 42 |

التطبيق

- وصلات انتقالية بحجم المعدات: مداخل/مخارج صمامات المضخات، وأنابيب الضاغط، وتحقيق انعطافات بزاوية قائمة + انتقالات قطر الأنبوب (على سبيل المثال، أنبوب رئيسي 4 بوصة إلى وصلة معدات 3 بوصة).

- الأنابيب الدقيقة للأجهزة: مقاييس الضغط، وفروع أجهزة الاستشعار، والتحويلات ذات القطر الصغير الحجم (على سبيل المثال، 1 بوصة × 1/2 بوصة) مطابقة بدقة للواجهات الملولبة للأجهزة.

- تحديث نظام البخار: أنابيب بخار منخفضة الضغط في غرف الغلايات (الفئة 150)، مقاومة لدرجات الحرارة من -29 درجة مئوية إلى 66 درجة مئوية، مع طلاء مجلفن بالغمس الساخن لمنع التآكل الناتج عن التكثيف.

- التحكم في السوائل ذات الضغط العالي: المحطات الهيدروليكية وأنظمة ضاغط الهواء (الفئة 300)، مع معدل ضغط 2000 رطل لكل بوصة مربعة لضمان السلامة.

- تكامل المعدات المتنقلة: خطوط وقود/هيدروليكية لآلات الإنشاء، ووصلات ملولبة مقاومة للاهتزاز، وسريعة التفكيك والصيانة.

المزايا

- تغطية تصنيف الضغط المزدوج:

- الفئة 150: الفئة الاقتصادية، تغطي الأنظمة التقليدية 300 رطل لكل بوصة مربعة;

- الفئة 300: خاصة بالضغط العالي، وتتحمل ضغط انفجار 2000 رطل في البوصة المربعة دون تعطل، وتحسن عامل الأمان بمقدار 60%.

- تصميم مقاوم للزلازل ومقاوم للتصدع: حديد الزهر المطاطي (ASTM A197) ذو ليونة ممتازة، مما يوفر مقاومة أعلى لصدمات المطرقة المائية 35% مقارنةً بحديد الزهر العادي.

- هيكل ذكي متغير القطر ذكي:

- الانتقال السلس للجدار الداخلي (على سبيل المثال، 4 بوصة × 3 بوصة)، مع توهين تغير سرعة التدفق <8%;

- مانع تسرب مزدوج الطرف ملولب NPT، معتمد من UL/FM مع عدم وجود تسرب.

- حماية كاملة من التآكل في البيئة المحيطة:

- طلاء مجلفن بالغمس الساخن مع مقاومة رذاذ الملح >800 ساعة، مناسب لمحطات الطاقة الساحلية والمصانع الكيميائية;

- إصدار من الحديد الأسود مع معالجة السطح بالفوسفات لتلبية متطلبات الوقاية من الصدأ في البيئات الجافة.

- تركيب سريع لمدة 90 ثانية: توصيل مباشر ملولب بدون أدوات، مما يوفر 4 ساعات لكل وصلة مقارنةً بالأكواع الملحومة.

التعبئة

- حماية الدروع الملولبة:

- يتم طلاء الأطراف الملولبة بشحم مضاد للصدأ يدوم طويلاً، ويتم إحكام غلقها مرتين بأغطية سيليكون وغشاء قابل للتقلص بالحرارة.

- يتم تغليف أجسام المرفقين بقطن اللؤلؤ وتغليفها بقوالب إسفنجية مخصصة لمنع اصطدامها بوسائل النقل.

- عبوات متدرجة الضغط:

- الفئة 150: صناديق ذات علامات زرقاء، 25 قطعة في كل صندوق (≤1″)، مع فواصل ورقية داخلية ومواد مجففة.

- الفئة 300: علبة ذات ملصق أحمر، 10 قطع في كل علبة (مكونات الضغط العالي معبأة بشكل منفصل)، مع ملصق تحذير “ضغط عالٍ” مطبوع على العلبة.

- حل ثوري للمكونات الكبيرة:

- ≥3 ″ أكواع تستخدم صناديق إطارات فولاذية قابلة لإعادة التدوير مزودة بشرائح RFID مدمجة للمسح الضوئي للحصول على معلمات عزم دوران التركيب;

- تحتوي الصناديق الخشبية على نوابض ممتصة للصدمات مثبتة في الزوايا الأربع، تجتاز معيار اختبار السقوط من ارتفاع 1.5 متر.

- نظام التحقق من الأخطاء وإمكانية التتبع:

- تعريف تصنيف ضغط صب المنتج (على سبيل المثال، “CL300”);

- صناديق خارجية موسومة بعلامات تحويل القطر (على سبيل المثال، “2” × 1“ → DN50 × 25”)، لمنع سوء الاستخدام في مواقع البناء.

الحجم المتاح

الحجم | A | B | ||

بوصة | دن | مم | مم | مم |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 26.4 | 26.2 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 28.5 | 28.7 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 30.5 | 31 |

1″ x 1/4″ | 25 x 8 | 33.4 x 13.7 | 27 | 31 |

1″ x 3/8″ | 25 x 10 | 33.4 x 17.1 | 30 | 32.3 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 32 | 35.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 34.8 | 36.8 |

1-1/4″ x 3/8″ | 32 x 10 | 42.2 x 17.1 | 32 | 36.5 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 34 | 38.9 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 36.8 | 41.2 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 40.1 | 42.4 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 35 | 41.5 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 38.6 | 44.5 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 41.9 | 45.7 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 37.5 | 47.5 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 40.6 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 43.9 | 51.3 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 48.3 | 53.3 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 51.3 | 54.9 |

2-1/2″ x 3/4″ | 65 x 20 | 73.0 x 26.7 | 42 | 57 |

2-1/2″ x 1″ | 65 x 25 | 73.0 x 33.4 | 46 | 58.7 |

2-1/2″ x 1-1/4″ | 65 x 32 | 73.0 x 42.2 | 50.5 | 60 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 54.9 | 63.8 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 60.7 | 66 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.7 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.4 | 50 | 67.5 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.2 | 55 | 70 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 58 | 72 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73.4 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 71.9 | 75.9 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.2 | 60 | 85 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 62 | 85 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 69 | 87 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 73.0 | 78 | 90 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 83.8 | 91.4 |

1/2″x 3/8″ | 15 x 10 | 21.3 x 17.1 | 30.2 | 30.2 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 38.1 | 39.6 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 36.5 | 42 |

- وصلات انتقالية بحجم المعدات: مداخل/مخارج صمامات المضخات، وأنابيب الضاغط، وتحقيق انعطافات بزاوية قائمة + انتقالات قطر الأنبوب (على سبيل المثال، أنبوب رئيسي 4 بوصة إلى وصلة معدات 3 بوصة).

- الأنابيب الدقيقة للأجهزة: مقاييس الضغط، وفروع أجهزة الاستشعار، والتحويلات ذات القطر الصغير الحجم (على سبيل المثال، 1 بوصة × 1/2 بوصة) مطابقة بدقة للواجهات الملولبة للأجهزة.

- تحديث نظام البخار: أنابيب بخار منخفضة الضغط في غرف الغلايات (الفئة 150)، مقاومة لدرجات الحرارة من -29 درجة مئوية إلى 66 درجة مئوية، مع طلاء مجلفن بالغمس الساخن لمنع التآكل الناتج عن التكثيف.

- التحكم في السوائل ذات الضغط العالي: المحطات الهيدروليكية وأنظمة ضاغط الهواء (الفئة 300)، مع معدل ضغط 2000 رطل لكل بوصة مربعة لضمان السلامة.

- تكامل المعدات المتنقلة: خطوط وقود/هيدروليكية لآلات الإنشاء، ووصلات ملولبة مقاومة للاهتزاز، وسريعة التفكيك والصيانة.

- تغطية تصنيف الضغط المزدوج:

- الفئة 150: الفئة الاقتصادية، تغطي الأنظمة التقليدية 300 رطل لكل بوصة مربعة;

- الفئة 300: خاصة بالضغط العالي، وتتحمل ضغط انفجار 2000 رطل في البوصة المربعة دون تعطل، وتحسن عامل الأمان بمقدار 60%.

- تصميم مقاوم للزلازل ومقاوم للتصدع: حديد الزهر المطاطي (ASTM A197) ذو ليونة ممتازة، مما يوفر مقاومة أعلى لصدمات المطرقة المائية 35% مقارنةً بحديد الزهر العادي.

- هيكل ذكي متغير القطر ذكي:

- الانتقال السلس للجدار الداخلي (على سبيل المثال، 4 بوصة × 3 بوصة)، مع توهين تغير سرعة التدفق <8%;

- مانع تسرب مزدوج الطرف ملولب NPT، معتمد من UL/FM مع عدم وجود تسرب.

- حماية كاملة من التآكل في البيئة المحيطة:

- طلاء مجلفن بالغمس الساخن مع مقاومة رذاذ الملح >800 ساعة، مناسب لمحطات الطاقة الساحلية والمصانع الكيميائية;

- إصدار من الحديد الأسود مع معالجة السطح بالفوسفات لتلبية متطلبات الوقاية من الصدأ في البيئات الجافة.

- تركيب سريع لمدة 90 ثانية: توصيل مباشر ملولب بدون أدوات، مما يوفر 4 ساعات لكل وصلة مقارنةً بالأكواع الملحومة.

- حماية الدروع الملولبة:

- يتم طلاء الأطراف الملولبة بشحم مضاد للصدأ يدوم طويلاً، ويتم إحكام غلقها مرتين بأغطية سيليكون وغشاء قابل للتقلص بالحرارة.

- يتم تغليف أجسام المرفقين بقطن اللؤلؤ وتغليفها بقوالب إسفنجية مخصصة لمنع اصطدامها بوسائل النقل.

- عبوات متدرجة الضغط:

- الفئة 150: صناديق ذات علامات زرقاء، 25 قطعة في كل صندوق (≤1″)، مع فواصل ورقية داخلية ومواد مجففة.

- الفئة 300: علبة ذات ملصق أحمر، 10 قطع في كل علبة (مكونات الضغط العالي معبأة بشكل منفصل)، مع ملصق تحذير “ضغط عالٍ” مطبوع على العلبة.

- حل ثوري للمكونات الكبيرة:

- ≥3 ″ أكواع تستخدم صناديق إطارات فولاذية قابلة لإعادة التدوير مزودة بشرائح RFID مدمجة للمسح الضوئي للحصول على معلمات عزم دوران التركيب;

- تحتوي الصناديق الخشبية على نوابض ممتصة للصدمات مثبتة في الزوايا الأربع، تجتاز معيار اختبار السقوط من ارتفاع 1.5 متر.

- نظام التحقق من الأخطاء وإمكانية التتبع:

- تعريف تصنيف ضغط صب المنتج (على سبيل المثال، “CL300”);

- صناديق خارجية موسومة بعلامات تحويل القطر (على سبيل المثال، “2” × 1“ → DN50 × 25”)، لمنع سوء الاستخدام في مواقع البناء.

احصل على عرض أسعار أنابيب الصلب المخصصة اليوم!

زوّدنا بتفاصيل مشروعك (مثل التطبيق والمواصفات والكمية). سيقدم لك فريقنا المتمرس حلاً مخصصاً وعرض أسعار تنافسي في غضون 24 ساعة عمل.