HOT PRODUCTS TAGS

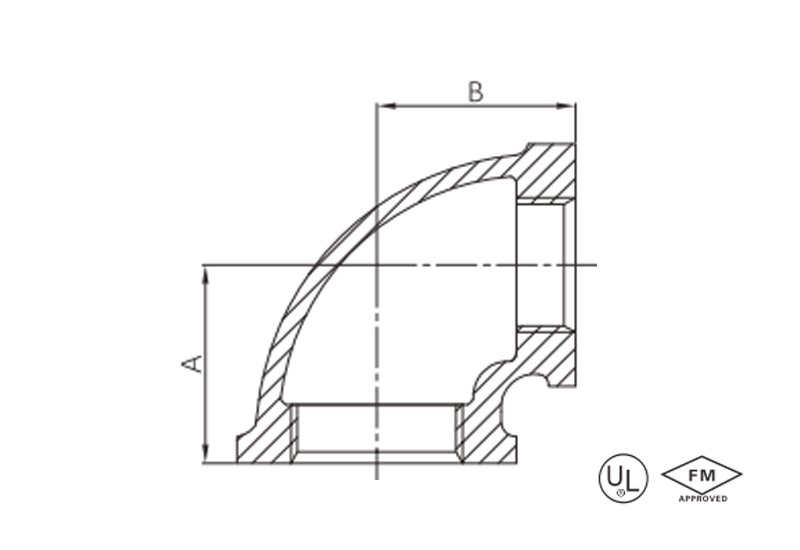

Malleable iron 90° reducing elbow

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ x 3/8″—4″ x 3″ (Class 150)

1/2″x 3/8″ —1-1/4″ x 1/2″ (Class 300)

description

Malleable iron 90° reducing elbow, pressure and corrosion resistant, suitable for various pipelines, easy to install, with excellent performance.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 26.4 | 26.2 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 28.5 | 28.7 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 30.5 | 31 |

1″ x 1/4″ | 25 x 8 | 33.4 x 13.7 | 27 | 31 |

1″ x 3/8″ | 25 x 10 | 33.4 x 17.1 | 30 | 32.3 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 32 | 35.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 34.8 | 36.8 |

1-1/4″ x 3/8″ | 32 x 10 | 42.2 x 17.1 | 32 | 36.5 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 34 | 38.9 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 36.8 | 41.2 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 40.1 | 42.4 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 35 | 41.5 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 38.6 | 44.5 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 41.9 | 45.7 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 37.5 | 47.5 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 40.6 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 43.9 | 51.3 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 48.3 | 53.3 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 51.3 | 54.9 |

2-1/2″ x 3/4″ | 65 x 20 | 73.0 x 26.7 | 42 | 57 |

2-1/2″ x 1″ | 65 x 25 | 73.0 x 33.4 | 46 | 58.7 |

2-1/2″ x 1-1/4″ | 65 x 32 | 73.0 x 42.2 | 50.5 | 60 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 54.9 | 63.8 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 60.7 | 66 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.7 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.4 | 50 | 67.5 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.2 | 55 | 70 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 58 | 72 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73.4 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 71.9 | 75.9 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.2 | 60 | 85 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 62 | 85 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 69 | 87 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 73.0 | 78 | 90 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 83.8 | 91.4 |

1/2″x 3/8″ | 15 x 10 | 21.3 x 17.1 | 30.2 | 30.2 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 38.1 | 39.6 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 36.5 | 42 |

application

- Equipment size transition connections: Pump valve inlets/outlets, compressor piping, simultaneously achieving right-angle turns + pipe diameter transitions (e.g., 4“ main pipe to 3” equipment interface).

- Instrument precision piping: Pressure gauges, sensor branches, small-size diameter transitions (e.g., 1“ × 1/2”) precisely matching instrument threaded interfaces.

- Steam system retrofit: Low-pressure steam pipes in boiler rooms (Class 150), temperature-resistant from -29°C to 66°C, with hot-dip galvanized coating to prevent condensation corrosion.

- High-pressure fluid control: Hydraulic stations and air compressor systems (Class 300), with 2000 psi pressure rating for safety assurance.

- Mobile equipment integration: Fuel/hydraulic lines for construction machinery, threaded connections resistant to vibration, quick disassembly and maintenance.

advantages

- Dual pressure rating coverage:

- Class 150: Economy class, covers conventional 300 psi systems;

- Class 300: High-pressure specific, withstands 2000 psi burst pressure without failure, and improves safety factor by 60%.

- Earthquake-resistant and crack-resistant design: Ductile cast iron (ASTM A197) with excellent ductility, providing 35% higher resistance to water hammer impact compared to ordinary cast iron.

- Intelligent variable-diameter structure:

- Smooth inner wall transition (e.g., 4“×3”), with flow velocity change attenuation <8%;

- NPT threaded double-end sealing, UL/FM certified with zero leakage.

- Full-environment corrosion protection:

- Hot-dip galvanized coating with salt spray resistance >800 hours, suitable for coastal power plants and chemical plants;

- Black iron version with phosphated surface treatment, meeting rust prevention requirements in dry environments.

- 90-second rapid installation: Threaded direct connection without tools, saving 4 hours per joint compared to welded elbows.

packing

- Threaded Armor Protection:

- Threaded ends are coated with long-lasting anti-rust grease, and double-sealed with silicone caps and heat-shrinkable film.

- Elbow bodies are wrapped in pearl cotton and embedded in custom foam molds to prevent transportation collisions.

- Pressure-graded packaging:

- Class 150: Blue-labeled boxes, 25 pieces per box (≤1″), with internal paper dividers and desiccants.

- Class 300: Red-labeled box, 10 pieces per box (high-pressure components packaged separately), with “High Pressure” warning label printed on the box.

- Revolutionary Solution for Large Components:

- ≥3″ elbows use recyclable steel frame boxes with embedded RFID chips for scanning to obtain installation torque parameters;

- Wooden boxes have shock-absorbing springs installed at the four corners, passing a 1.5-meter drop test standard.

- Error-proofing and traceability system:

- Product casting pressure rating identification (e.g., “CL300”);

- Outer boxes labeled with diameter conversion tags (e.g., “2” × 1“ → DN50 × 25”), to prevent misapplication at construction sites.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.1 | 26.4 | 26.2 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.1 | 28.5 | 28.7 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 30.5 | 31 |

1″ x 1/4″ | 25 x 8 | 33.4 x 13.7 | 27 | 31 |

1″ x 3/8″ | 25 x 10 | 33.4 x 17.1 | 30 | 32.3 |

1″ x 1/2″ | 25 x 15 | 33.4 x 21.3 | 32 | 35.5 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 34.8 | 36.8 |

1-1/4″ x 3/8″ | 32 x 10 | 42.2 x 17.1 | 32 | 36.5 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 34 | 38.9 |

1-1/4″ x 3/4″ | 32 x 20 | 42.2 x 26.7 | 36.8 | 41.2 |

1-1/4″ x 1″ | 32 x 25 | 42.2 x 33.4 | 40.1 | 42.4 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 35 | 41.5 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.7 | 38.6 | 44.5 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.4 | 41.9 | 45.7 |

2″ x 1/2″ | 50 x 15 | 60.3 x 21.3 | 37.5 | 47.5 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.7 | 40.6 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.4 | 43.9 | 51.3 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.2 | 48.3 | 53.3 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 51.3 | 54.9 |

2-1/2″ x 3/4″ | 65 x 20 | 73.0 x 26.7 | 42 | 57 |

2-1/2″ x 1″ | 65 x 25 | 73.0 x 33.4 | 46 | 58.7 |

2-1/2″ x 1-1/4″ | 65 x 32 | 73.0 x 42.2 | 50.5 | 60 |

2-1/2″ x 1-1/2″ | 65 x 40 | 73.0 x 48.3 | 54.9 | 63.8 |

2-1/2″ x 2″ | 65 x 50 | 73.0 x 60.3 | 60.7 | 66 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.7 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.4 | 50 | 67.5 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.2 | 55 | 70 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 58 | 72 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73.4 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 73.0 | 71.9 | 75.9 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.2 | 60 | 85 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 62 | 85 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 69 | 87 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 73.0 | 78 | 90 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 83.8 | 91.4 |

1/2″x 3/8″ | 15 x 10 | 21.3 x 17.1 | 30.2 | 30.2 |

1″ x 3/4″ | 25 x 20 | 33.4 x 26.7 | 38.1 | 39.6 |

1-1/4″ x 1/2″ | 32 x 15 | 42.2 x 21.3 | 36.5 | 42 |

- Equipment size transition connections: Pump valve inlets/outlets, compressor piping, simultaneously achieving right-angle turns + pipe diameter transitions (e.g., 4“ main pipe to 3” equipment interface).

- Instrument precision piping: Pressure gauges, sensor branches, small-size diameter transitions (e.g., 1“ × 1/2”) precisely matching instrument threaded interfaces.

- Steam system retrofit: Low-pressure steam pipes in boiler rooms (Class 150), temperature-resistant from -29°C to 66°C, with hot-dip galvanized coating to prevent condensation corrosion.

- High-pressure fluid control: Hydraulic stations and air compressor systems (Class 300), with 2000 psi pressure rating for safety assurance.

- Mobile equipment integration: Fuel/hydraulic lines for construction machinery, threaded connections resistant to vibration, quick disassembly and maintenance.

- Dual pressure rating coverage:

- Class 150: Economy class, covers conventional 300 psi systems;

- Class 300: High-pressure specific, withstands 2000 psi burst pressure without failure, and improves safety factor by 60%.

- Earthquake-resistant and crack-resistant design: Ductile cast iron (ASTM A197) with excellent ductility, providing 35% higher resistance to water hammer impact compared to ordinary cast iron.

- Intelligent variable-diameter structure:

- Smooth inner wall transition (e.g., 4“×3”), with flow velocity change attenuation <8%;

- NPT threaded double-end sealing, UL/FM certified with zero leakage.

- Full-environment corrosion protection:

- Hot-dip galvanized coating with salt spray resistance >800 hours, suitable for coastal power plants and chemical plants;

- Black iron version with phosphated surface treatment, meeting rust prevention requirements in dry environments.

- 90-second rapid installation: Threaded direct connection without tools, saving 4 hours per joint compared to welded elbows.

- Threaded Armor Protection:

- Threaded ends are coated with long-lasting anti-rust grease, and double-sealed with silicone caps and heat-shrinkable film.

- Elbow bodies are wrapped in pearl cotton and embedded in custom foam molds to prevent transportation collisions.

- Pressure-graded packaging:

- Class 150: Blue-labeled boxes, 25 pieces per box (≤1″), with internal paper dividers and desiccants.

- Class 300: Red-labeled box, 10 pieces per box (high-pressure components packaged separately), with “High Pressure” warning label printed on the box.

- Revolutionary Solution for Large Components:

- ≥3″ elbows use recyclable steel frame boxes with embedded RFID chips for scanning to obtain installation torque parameters;

- Wooden boxes have shock-absorbing springs installed at the four corners, passing a 1.5-meter drop test standard.

- Error-proofing and traceability system:

- Product casting pressure rating identification (e.g., “CL300”);

- Outer boxes labeled with diameter conversion tags (e.g., “2” × 1“ → DN50 × 25”), to prevent misapplication at construction sites.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.