A Guide to Pipe Schedule: Understanding Sch 40 & Sch 80?

Introduction): the procurement of steel pipes and engineering design, “Wall Thickness Number (Sch)” (abbreviated as Sch) is a term that is frequently encountered but often misunderstood. It does not directly represent the wall thickness value, but serves as an identification system in North American standards (such as ANSI/ASME B36.10, B36.19) for standardizing the wall thickness grades of steel pipes. This standardized design aims to address the confusion regarding wall thickness among different manufacturers and specifications. It enables global users to quickly identify the pressure-bearing capacity and applicable uses of pipes through the “Sch + digital” marking, thereby avoiding safety hazards caused by mismatched wall thickness.

Today, Sch40 and Sch80 are the two most commonly used grades in engineering, corresponding respectively to “standard pressure operating conditions” and “medium and high pressure operating conditions”, and they are also the two specifications that users are most likely to confuse when selecting models.

1.Core differences: Sch40 and Sch80

The fundamental difference between Sch40 and Sch80 lies in “wall thickness grade and pressure-bearing capacity”. However, in practical applications, this difference extends to multiple dimensions such as inner diameter, weight, and applicable scenarios. The following “Key Parameter Comparison Table” and “Core Difference Analysis” clearly demonstrate the differences between them:

Key Parameters Comparison of Sch40 and Sch80 Steel Pipes at Common Nominal Diameters (Compliant with ANSI/ASME B36.10M Standard, Material: Carbon Steel A106 B):

| Nominal Diameter (inches) | Steel Pipe Outer Diameter (mm) | Sch40 – Wall Thickness (mm) | SCH40 Maximum allowable pressure in water at 20°C (MPa) | Sch80 – Wall Thickness (mm) | SCH80 Maximum allowable pressure in water at 20°C (MPa) |

| 1/2 | 21.34 | 3.73 | 10.3 | 5.56 | 15.1 |

| 1 | 33.4 | 3.38 | 8.6 | 4.55 | 11.7 |

| 2 | 60.33 | 3.91 | 6.8 | 5.54 | 9.3 |

| 4 | 114.3 | 6.02 | 5.2 | 8.56 | 7.1 |

| 6 | 168.28 | 7.11 | 4.5 | 10.16 | 6.2 |

| 8 | 219.08 | 8.18 | 4.0 | 12.7 | 5.5 |

Explanation of main differences:

(1).Wall thickness and pressure rating: Sch80 “Thick wall, high pressure rating”; Sch40 “Thin Wall, Standard Pressure Rating”

As shown in the table data, under the same nominal diameter, the wall thickness of Sch80 is always greater than that of Sch40. As the diameter increases, this difference becomes more pronounced: the wall thickness difference between 1-inch Sch40 and Sch80 pipes is 1.17 millimeters, while that of 8-inch pipes reaches 4.52 millimeters. This difference in wall thickness directly determines their pressure-bearing capacity. According to the ASME B31.3 standard, under the same material (A106 B) and temperature (20°C) conditions, the maximum allowable pressure of the Sch80 pipe is 30%-50% higher than that of the Sch40 pipe. For instance, the maximum allowable pressure of the Sch80 pipeline can reach 7.1 MPa, meeting the requirements for medium and high-pressure fluid transportation (such as high-pressure natural gas and feed pipelines for chemical reactors).

(2). Inner diameter and flow rate: Sch40 “Larger inner diameter, higher flow rate”; Sch80 “Small inner diameter, low flow rate

Due to the thicker pipe wall, the inner diameter of Sch80 pipes is smaller than that of Sch40 pipes of the same nominal size. For instance, the inner diameter of a 2-inch Sch40 pipe is 52.51 millimeters, while that of a 2-inch Sch80 pipe is 49.25 millimeters, with a difference of approximately 6.2%. This inner diameter difference directly affects the fluid transportation efficiency: at the same flow rate, the flow rate of the Sch40 pipe is approximately 12.7% higher than that of the Sch80 pipe (based on the flow rate formula Q=πr²v, where the flow rate is proportional to the square of the inner diameter).

(3). Weight and cost: Sch80 is “heavier and more expensive”, while Sch40 is “lighter and more economical”.

The difference in wall thickness directly affects weight and cost: Sch80 pipes of the same diameter weigh 30% to 60% more per meter than Sch40 pipes, resulting in higher material costs. For instance, for a 4-inch pipe, the weight per meter of Sch40 steel pipe is 16.87 kilograms, while that of Sch80 steel pipe is 23.09 kilograms, an increase of 37% in weight per meter. For a project that requires 1,000 meters of 4-inch pipes, choosing Sch80 steel pipes will increase the steel consumption by approximately 6.22 tons and the material cost by about 30,000 yuan compared to choosing Sch40 steel pipes (calculated at 6,000 yuan per ton for carbon steel).

2.How to Select the Right Pipe Schedule for Your Application?

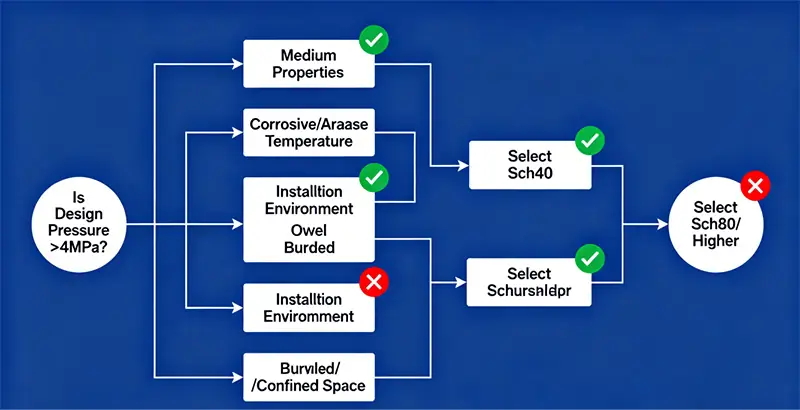

When choosing between Sch40 and Sch80, the key lies in “matching the operating conditions”—neither should you opt for “lower Sch pipes” to save costs, creating safety hazards, nor should you choose “higher Sch pipes” solely for safety, resulting in waste. The following four core selection principles will help you make quick decisions based on specific scenarios.

Principle 1: Determine the Sch rating based on “design pressure,” the core selection criterion.

Design pressure is the maximum pressure the piping system will experience during normal operation (including additional pressures like pressure fluctuations and water hammer) and must match the pipe’s allowable pressure. The specific judgment logic is as follows:

Give priority to recognized pressure gauges: Determine the corresponding Sch according to the steel pipe material (e.g. Carbon steel A106 B, stainless steel 304) and design temperature (e.g. Ambient temperature 20°C, high-temperature temperature 100°C), in accordance with ANSI/ASME B36.10 or industry standards (e.g. GB/T 20801).

Example : The design pressure of the municipal water supply network is 0.8MPa, the temperature is 20°C, and the material is carbon steel A106 B. Referring to the allowable pressure gauge, the allowable pressure of the 2-inch Sch40 steel pipe is 6.8MPa, which is much higher than 0.8MPa. Therefore, Sch40 is appropriate;

Principle Two: Determine whether to increase the Sch grade based on the “medium characteristics”

The physical and chemical properties of the medium will affect the actual load-bearing capacity of the steel pipe. Even if the design pressure is the same, the Sch grades required for different media may also vary:

Corrosive media: For instance, transporting seawater containing chloride ions or natural gas containing hydrogen sulfide. These media will slowly corrode the pipe wall, causing it to thin. In this case, it is recommended to increase the Sch grade by one level on the basis of the “pressure matching Sch grade” (for example, from Sch40 to Sch80). This can be achieved by increasing the initial wall thickness to extend the service life of the pipe.

Abrasive medium: When transporting slurry containing particles or coal powder, the medium will erode the pipe wall, causing the local wall thickness to become thinner. In this case, steel pipes of a higher Sch grade (such as Sch80) should be selected. These steel pipes have thicker walls that are more wear-resistant, which can prevent perforation and leakage caused by local thinning of the wall thickness.

Principle Three: Adjust the Sch plan according to the “installation environment and structural requirements”

The installation environment and structural design will also affect the choice of the Sch plan. Common situations include:

Buried pipelines: Buried pipelines bear the external pressure of the soil. The larger the pipe diameter, the greater the risk of unstable external pressure. For buried pipelines with a nominal diameter of ≥6 inches, it is recommended to use Sch40 or higher grade pipes even at lower design pressures (for example, 1.0MPa).

Overhead pipelines: Overhead pipelines rely on supports to bear their weight. For large spans (e.g., >6 meters), the “thick-walled structure” of Sch80 pipes can enhance their rigidity and reduce bending deformation.

3.Conclusion – Safe and efficient, choose the right steel pipe

Choosing Sch grade steel pipes may seem like a “simple difference in wall thickness”, but in fact, it is an “art of balancing safety, efficiency and cost”. Wrong choices not only lead to safety accidents such as pipeline leakage or explosion, but also cause material waste or low transportation efficiency. Sch40 steel pipes feature “thin wall thickness, large inner diameter and low cost”, and are suitable for standard pressure and high flow scenarios.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- 3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

- ASTM A53 LSAW Steel Pipe Selection Guide for Oil and Gas Transportation Pipelines

- API 5L LSAW Pipe: A Deep Dive into PSL1 vs. PSL2

- Steel Pipe Sizing Errors? DN vs. OD Explained for Buyers

- NDT for Pipe Welds: X-ray vs. Ultrasonic Testing