Choosing Sprinkler Pipe: Sch 10 vs. Sch 40 Guide

Introduction

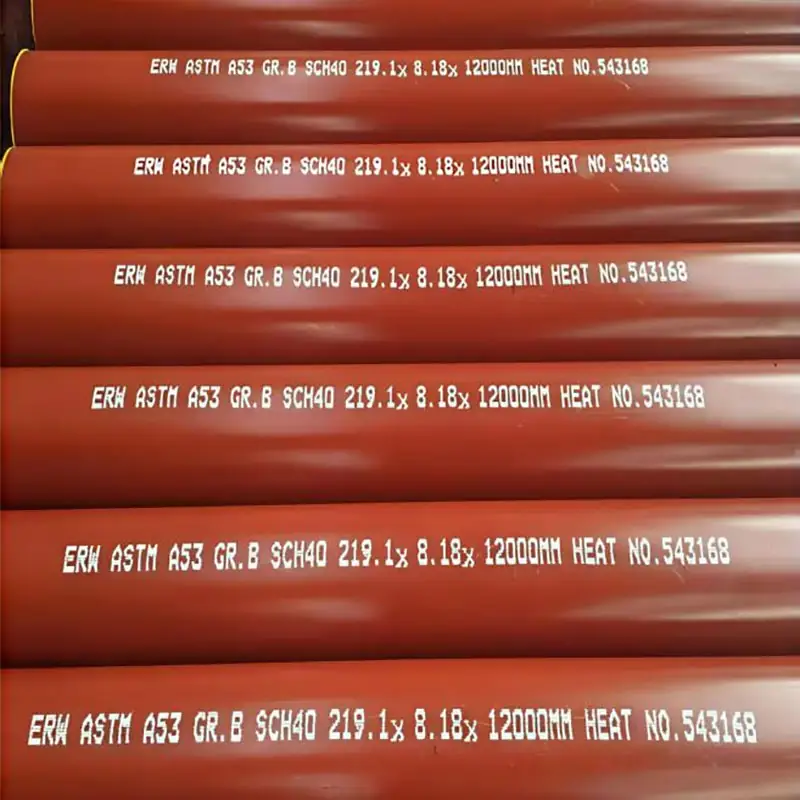

You are a fire protection engineer in the design phase of the new commercial building, and you are calculating hydraulics for the automatic sprinkler system. The NFPA 13 standard lays out the roadmap, but in your calculations one of your key variables is the inside diameter of the pipe. This single value, based on pipe nominal size and its Schedule number, will have a direct impact on friction loss, flow velocity and at the end of the day if the system is capable of providing the required volume density of water at the further distance sprinkler. The decision between a thin wall pipe such as Schedule 10 and a regular wall like Schedule 40 looks easy, but it ripples to the entire system design and cost.

Understanding how the physical dimensions of a pipe translate directly into its hydraulic and structural capabilities is the essence of this engineering decision. Without performing proper analysis, when you just go with cheapest option, you can wind up with a system that won’t pass it’s hydraulics and you’ll have to purchase a larger, more expensive fire pump. On the other hand, over-engineering a heavy wall pipe for a regular application may significantly increase material and labor cost. The ideal design requires a fine, data-driven balance of hydraulic performance and project economics.

This article provides a technical, engineer-oriented sprinkler pipe sizing guide and will focus on the influence of the pipe Schedule number. We will discuss how the new thickness of Schedule 10 Pipe vs. Schedule 40 Pipe affects hydraulic calculations according to the Hazen-Williams formula.In addition, to help you decide and know what are you talking about, we have prepared a chart comparing side by side these two popular schedules with respect to pressure ratings, weight, cost and common uses and applications with it all in one clear sheet so that you can make the best possible and most cost efficient design decision.

1. What is a Pipe Schedule Number? More Than Just a Name

The “Schedule” (Sch) number is part of a North American standard that expresses the thickness of the walls of a steel pipe. It is not a measurement in mm or inches. For a given nominal pipe size (NPS), a larger schedule number means a thicker pipe wall, which results in a smaller inner diameter. 4 inch NPS Sch 40 pipe will have the considerably thick wall and less inside diameter than 4 inch NPS Sch 10 pipe.

This difference in inner diameter is the single most important factor to a fire protection engineer, because it is what directly controls the cross-sectional area through which water flows.As we shall see, the smallest variation in this diameter, alters the system’s hydraulic performance immensely.

2. The Hydraulic Heartbeat: The Hazen-Williams Formula

The backbone of sprinkler system hydraulic calculations is the Hazen-Williams formula, which calculates the pressure loss due to friction as water moves through a pipe. The formula is expressed as:

p = 4.52 * Q^1.85 / (C^1.85 * d^4.87)

Where:

· p = Frictional pressure loss in psi per foot of pipe

· Q = Flow rate in gallons per minute (GPM)

· C = Hazen-Williams friction loss coefficient (a constant, typically 120 for new wet-pipe steel)

· d = The actual internal diameter of the pipe in inches

The most potent variable in this equation is d, the inner diameter, information since it is raised to 4.87. This is to say that a reduction in the inner diameter leads to an exponential increase in the friction losses. This is the main reason that the choice between Sch 10 and Sch 40 matters; their internal diameters differences will produce radically different pressure loss predictions for the same flow rate.A system design with Sch 10 pipe will find that the pressure requirements are easily met, but the same design with the narrower Sch 40 pipe may find that it needs larger pipe sizes upstream or a more powerful fire pump, as the pressure requirements are not met at that point.

3. Quantitative Analysis: Schedule 10 vs. Schedule 40 Decision Matrix

To make an informed decision, a direct, data-driven comparison is essential. The following table compares 4-inch Nominal Pipe Size (NPS) steel pipe in both schedules—a common size for sprinkler system risers and main lines.

| Parameter | Sch 10 Pipe (4-inch NPS) | Sch 40 Pipe (4-inch NPS) | Engineering Implication & Rationale |

| Actual Outer Diameter (OD) | 4.500 inches (114.3 mm) | 4.500 inches (114.3 mm) | The OD is constant for a given NPS, ensuring fittings are interchangeable. The difference is internal. |

| Nominal Wall Thickness | 0.120 inches (3.05 mm) | 0.237 inches (6.02 mm) | Sch 40 has nearly double the wall thickness of Sch 10, making it significantly more robust. |

| Actual Internal Diameter (d) | 4.260 inches (108.2 mm) | 4.026 inches (102.3 mm) | This is the critical variable. Sch 40’s smaller diameter will result in significantly higher friction loss per the Hazen-Williams formula. |

| Working Pressure Rating (A53) | ~700 psi | ~1500 psi | Sch 40’s thicker wall gives it a much higher pressure rating, making it suitable for systems with very high static pressures. |

| Weight per Foot | 5.56 lbs/ft (8.28 kg/m) | 10.79 lbs/ft (16.07 kg/m) | Sch 40 is almost twice as heavy, increasing structural load on supports and making it more difficult and costly to handle and install. |

| Relative Cost | Baseline (1.0x) | ~1.5x – 1.8x | The significant increase in steel content makes Sch 40 considerably more expensive from a material standpoint. |

| Primary Application (NFPA 13) | Standard for wet pipe sprinkler systems. Preferred where acceptable. | Required for dry pipe systems, pre-action systems, and any system subject to physical damage or high pressure. | Sch 10 is the hydraulically and economically efficient choice for the most common system types. Sch 40 is the mandatory choice for more demanding applications. |

4. The Practical Implications: Beyond the Numbers

The quantitative results show a distinct trade-off. Schedule 10 pipe’s thinner wall and larger internal diameter make it the best value hydraulic and economical option. Its increased bore diameter lowers friction loss, which may translate into smaller pipe sizes being calculated, a smaller fire pump, and considerable savings in matter and work of installation because of its lighter weight.

However when it comes to durability, Schedule 40 wins. It has historically been the only choice for impact resistance as its thick wall offers unparalleled impact resistance. Additionally, its elevated pressure rating is vital for high pressure system operation.Dry pipe and pre-action system: As a precaution against corrosion-related breaches, NFPA 13 typically requires heavier-walled pipe, such as Sch 40, for dry pipe and pre-action systems Provide an extra margin of safety these systems are pressurized with air and are much more at risk for internal corrosion.

Conclusion

Choosing a pipe schedule in a sprinkler system design is a basic engineering determination which concerns fluid flow, pressure, and cost on the project. The sch 10 vs sch 40 is not anywhere near a simple preference, it is a technical decision which depends on the system type, environment it is used in, and the severe implications in hydraulic calculation.The Outputs from This Analysis Provides a Decision Rule The key lessons comparing variable TOC with fixed TOC are clear and can be easily translated into a decision rule:

· Specify Schedule 10 when: The system is a typical wet pipe sprinkler system, the potential for severe mechanical damage is minimal, and hydraulic efficiency and cost are both key factors. Its larger internal diameter offers a clear advantage in reducing friction loss.

· Specify Schedule 40 when: The application is a dry pipe system, a pre-action system, or any system in the air or gas side of the pipe where the pipe might be exposed to physical damage. It is also the only choice for system components that are subjected to extremely high static or working pressures.

In the end, it’s a deep understanding of how those pipe physical characteristics influence the Hazen-Williams equations that differentiates a good design from an optimal one. An informed provisioner such as Allland Steel recognizes this vital correlation. We don’t just supply the materials, we also offer the engineering information and expertise to enable engineers and designers to make the most informed, code-compliant, and cost-effective decisions for their fire protection projects.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.