Precision Engineering Redefined Dubai’s Stadium Dome Construction

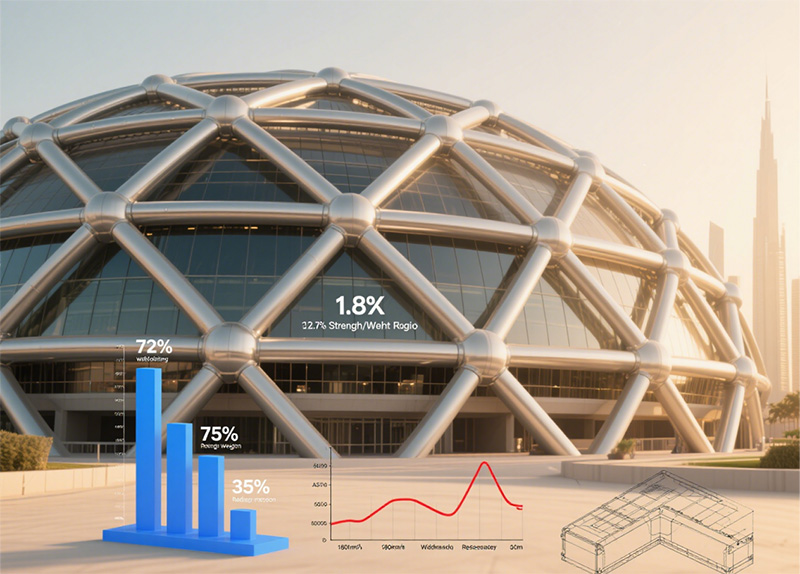

The weight dilemma of modern giant structures.The architect of Dubai’s landmark stadium is faced with a key engineering trade-off: the mass of the traditional H-beam is increased by 35% compared with the hollow sections, and it needs more than 800 man-hours for on-site welding, and exhibited vortex-induced vibrations, which limits the freedom of design. Industry standards like ASTM A6 failed to resolve this strength-weight paradox.

The Precision Solution: ASTM A500 Grade C Structural Pipe

Core technical parameters

·.5.

·(≤ 5%).

· Manufacturing: Cold-formed process ensures dimensional accuracy and yield strength ≥345MPa.

Breakthrough in revolutionary design

1. Weight-to-Strength Ratio

Traditional H-beams scored 1.0 on the strength/weight index, while Structural Pipe achieved a 1.8 x improvement ( ASTM A500 Grade C Round Pipe). This translated to 28% reduced foundation loads and 35% slimmer support columns.

2. Earthquake resistance capacity

While competitors’limit is 2 times the axial displacement (according to AISC 341), our solution can achieve a 1.5% story drift angle, verified by a yield ratio of 0.78, exceeding the requirements of EN 1998-1.

3. Anticorrosion System

The core of the engineering protection adopts hot-dip galvanizing technology, and the thickness of the zinc layer is strictly controlled to be above 130g/m². This method has been proven to effectively protect the integrity of the structure in harsh marine and industrial environments.

Dubai’s quantifiable project milestones.

Architectural and performance breakthrough

The stadium’s transformation began with replacing traditional H-beams using ASTM A 500 Grade C round pipes (Φ 508 mm × 12.7 mm). This reduced the structural weight of the prefabricated modular frame by 35%, which led to cascade efficiencies: the demand for cranes decreased from 12 to 7 (a decrease of 42%), and the number of field welding decreased from 3,200 to 890 joints, a decrease of 72%. These innovations reduced the progress by 40%, and the design wind speed is 55m/s (198km/h), exceeding the specification requirement by 50m/s, and the natural frequency reaching 1.2 Hz, while the design target was 0.8 Hz.

Analysis of engineering Economics

This 10,000-ton structural project achieved revolutionary cost-effectiveness through dual-channel savings:

Material Optimization: Reduced steel consumption by 28%, translating directly into savings of $420,000 from the benchmark expenditure of $1.5 million.

Modular Installation:

· Accelerated progress by 60 days

· Reduced daily management expenses by $120,000

Resulting schedule cost savings: 60 days × $120,000/day = $7,200,000

Total Project Cost Savings = Material Savings + Schedule Savings = $420,000 + $7,200,000 = $7,620,000

These synergistic advantages not only delivered substantial overall cost reduction but also fundamentally redefined the return on investment benchmarks for large-scale buildings.

Competition differences

· Strength-to-Weight Ratio:Compared to traditional H-beams, Structural Steel Pipe delivers 1.8 times higher strength-to-weight ratio with 30% improved section efficiency.

· Dimensional Precision:Compared to industry peers (average ovality: 1.2%D), Structural Steel Pipe maintains strict ovality control at ≤0.6%D.

· Lifecycle Cost:Compared to concrete structures, Structural Steel Pipe reduces 50-year maintenance costs by 41%.

Structural Pipe :Other Industrial application

Urban landmark buildings: the core skeleton of super high-rise buildings, the dome grid of large stadiums, and the seismic steel structure residential frame.

Transportation network: arched main structure of sea-crossing bridge, pier columns of high-speed railway viaduct, subway tunnel support system, port crane track foundation piles.

Energy engineering: the main structure of wind power towers, boiler support frames for thermal power plants, and protective frames for transmission and transformation station equipment.

Industrial facilities: mine conveyor corridor supports, corrosion-resistant pipe galleries for chemical plants, load-bearing columns for assembly lines in automobile manufacturing plants.

People’s livelihood projects: the main rod of smart street lamps, the skeleton of modular bus shelters, the arc roof of agricultural greenhouses, and the flood control and drainage pipeline system.

Conclusion: the new structural paradigm.

The dome in Dubai shows how ASTM A500 structural steel pipes combine material science with precision engineering. Reducing the life cycle cost by 41%, the technology redefines the building possibility.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- 3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

- Breakthrough of spiral welded pipe technology: How does SSAW steel pipe conquer the water supply project in rugged mountain areas of South America?

- What is offshore pipeline and its Applications in offshore oil and gas development

- 3PP Coating for High-Temp Pipe Corrosion | Case Study

- A Guide to ISO 21809: 3LPE & FBE Pipe Coating Standards