Steel Pipe Bevel Angle & Root Face Boost Welding Speed

Introduce

In the field of oil and gas (e.g. Long-distance transportation pipelines), chemical (reactor connecting pipeline) and municipal (water supply networks) industries, steel pipe are the core of fluid/gas transportation systems. On-site welding of steel pipe depends to a great extent on high-quality groove end-this is not a “finishing touch”, but the basic premise of efficient and high-quality welding. A well-processed welded steel pipe groove can eliminate 80% of common welding defects (such as incomplete fusion), reduce rework time by half, and finally cut down the overall project costs.

What is the bevel end on a steel pipe?

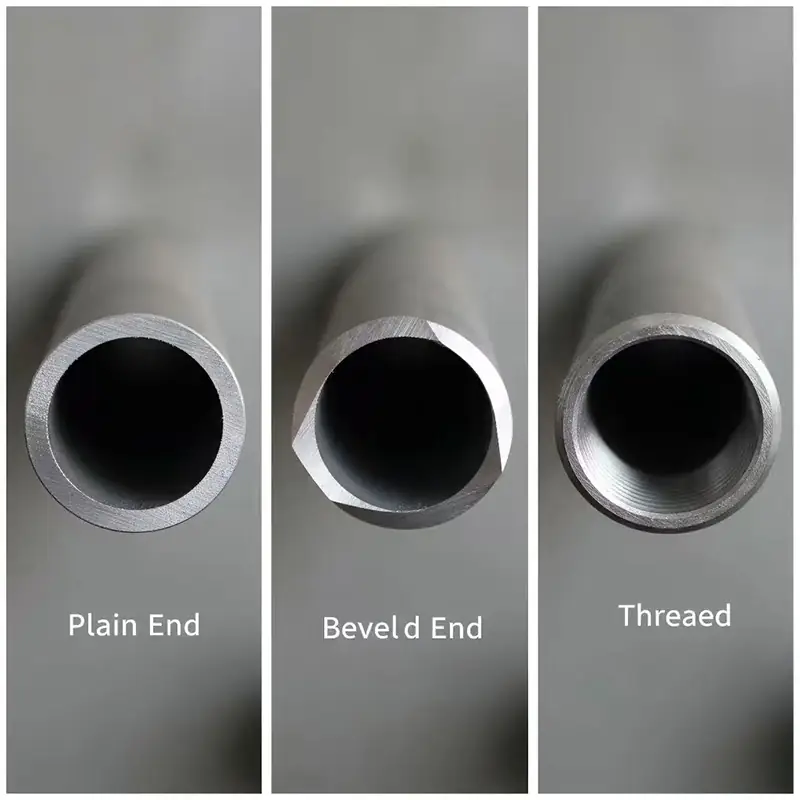

For welded steel pipe, groove refers to the precise inclined surface machined at the pipe end, which is specially designed to completely fuse the two steel pipes during welding process. Unlike flat ends (which is only applicable to flange connections requiring additional fasteners), the beveled ends is specially optimized for welding. Its core structure consists of two non-negotiable elements: bevel angle (which determines arc entrance) and root surface (which protects the integrity of pipeline).

Key Elements at the bevel end

· Oblique angle (30 standard): the fixed angle between the oblique angle surface and the outer wall of the pipeline, which is tested and verified through industrial practices.

· Root surface: 1-3 mm flat internal section (thickness adjusted according to pipe diameter: 1 mm for DN 50 pipeline and 3 mm for DN 2000 pipeline)

Why is the bevel angle 30 degrees?

· Full penetration: 30°creates the best opening for the arc-shaped channel-smaller angles (e.g. 20°) blocking arc, resulting in incomplete penetration; Larger angles (e.g. 45°) Usage of double filler metal.

· Welding compatibility: It completely matches SMAW (manual welding), GMAW (semi-automatic) and FCAW (flux-cored) processes, and there is no need to customize welding gun adjustments.

· Cost savings: For the same DN 150 steel pipe, 30°angles use 25% less filler metal than 45 ° angles, reducing material costs per joint by 15–30.

Root surface action

· Prevent burn-through: absorb excess welding heat (up to 3000℃) to protect the inner wall of the pipeline and avoid holes that need to be blocked.

· Strengthening joints: forming uniform root weld bead, which is very important for welding high-pressure steel pipe (e.g. An oil pipelines with a pressure of 10,000 pounds per square inch.

· Stabilize welding pool: prevent molten metal from dripping into the inside of the pipeline (called “sag”), otherwise it needs internal grinding to remove it.

Inclined plane quality and welding efficiency

Accelerate the welding speed

· No need for frequent adjustments: the accurate 30 angles allows the welders to fix the position of the welding torch at one time (for example. 15 from the pipeline axis), saving 30% installation time compared with irregular groove.

· Less passes: For DN 200 steel pipe, only 3-4 passes are needed for uniform groove; Irregular inclined plane needs 5-6 passes, and each joint needs 10-15 minutes.

Higher First-Time Pass Rate (FTPR)

· Elimination of defects: accurate angles and root surface reduce incomplete penetration and porosity-in a recent natural gas project, after switching to our steel pipe, FTPR increased from 78% to 96%.

· Inspection is easier: consistent welds speed up nondestructive testing (ultrasonic testing time for each joint is reduced from 10 minutes to 5 minutes).

Our steel pipes and welding steel pipes

Product scope

| Product Type | Material Grade | Diameter | Thickness | Bevel Angle | Root Face |

| Seamless Steel Pipe | API 5L X42-X80 | DN50-600 | 5–25mm | 30°±1° | 1–2mm |

| Longitudinal Welded | API 5L X42-X65 | DN100-1200 | 4–18mm | 30°±1° | 1–2.5mm |

| Spiral Welded | API 5L X42-X70 | DN200-2000 | 6–30mm | 30°±1° | 2–3mm |

Main characteristics

· Numerical control accuracy: 5-axis numerical control beveling machine is used to ensure the angular tolerance of 1 and the root tolerance of 0.5 mm (no manual errors)

· Surface treatment: After groove processing, the pipeline can be welded on site after shot peening (derusting) and antirust coating (protection for 6 months).

· Customizable: for special projects (e.g. Offshore steel pipe used for welding), angle can be adjusted to 35, and the root surface is 4 mm, which meets the ninth section standard of ASME BPVC.

Applications program

· Oil&gas: Cross-country/offshore pipelines (cuts welding time by 20–30%, critical for remote desert/offshore sites).

· Chemical: corrosion-resistant steel pipe for welding (316 l material option), with leak-proof joints, can be safely used for acid/alkali transportation.

· Power: high temperature (up to 500 C) and high pressure steam pipelines, which is compatible with welding requirements of power plant.

· Municipal: Water/sewage projects (fast welding reduces road closure time, minimizing traffic disruptions).

Conclusion

For welded steel pipes, the high-quality groove end is non-negotiable-the 30 angle ensures complete penetration, while the root surface ensures joint safety, which not only reduces the welding time, but also reduces the rework rates. Our factory uses advanced CNC technology to produce precise inclined steel pipe, which helps you to save 20-30% on on-site labor costs and meet project deadlines. Contact us now to get a solution for welding special steel pipes (e.g. Customize the diameters and materials to meet your specific needs.

Share:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.