LSAW Steel Pipe: In-Depth Product Review

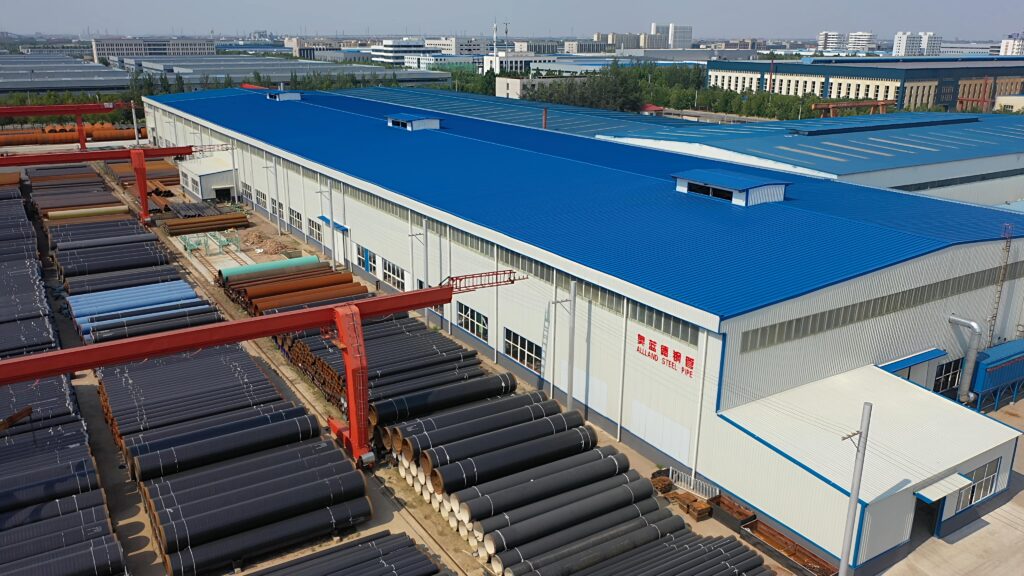

“Quality is not an act, it is a habit.” – Aristotle. Our company lives by this saying, ensuring every longitudinal submerged arc welded pipe meets high standards. Our Company is a trusted manufacturer of LSAW steel pipes for diverse industries worldwide , known for its commitment to quality and customer satisfaction. If top-quality LSAW pipe manufacturer are what you need, Our Company is the place to go. You can contact our team for inquiries and further information.

Key Takeaways

- Our Company is a trusted manufacturer of LSAW steel pipes.

- Our products cater to diverse industries worldwide.

- Our Company is committed to quality and customer satisfaction.

- You can contact us directly at

- Phone:+86 195 2338 1749

- Email:sales@alllandpipes.com.

What Makes LSAW Steel Pipe Superior?

LSAW steel pipes stand out due to their special manufacturing process and characteristics. The Longitudinal Submerged Arc Welding (LSAW) method creates top-notch steel pipes. These pipes are strong and last long.

Definition and Key Characteristics

LSAW steel pipes have a unique longitudinal seam. This seam is welded using submerged arc welding. This method makes the weld strong and precise. These pipes can handle high pressures and tough environments. They are also very robust, precise, and can be made in different sizes and thicknesses.

Manufacturing Process Overview

The making of LSAW steel pipes starts with steel plates being shaped into a cylinder. Then, the longitudinal seam is welded using submerged arc welding. This method ensures the pipes are of consistent quality and exact dimensions. This makes them perfect for important uses like oil and gas pipelines. This describes the LSAW pipe manufacturing process.

Comparison with ERW and Spiral Pipes

LSAW steel pipes are stronger and more durable than ERW and spiral pipes. ERW pipes are made by electrical resistance welding, and spiral pipes are formed by spirally welding steel plates. But LSAW pipes have a longitudinal seam that adds extra strength. This makes LSAW pipes great for applications that need high pressure.

LSAW Steel Pipe Features

Our LSAW steel pipes are made to perform well in many uses. They are designed to meet the needs of today’s big projects.

Product Specifications and Available Grades

Our LSAW pipes come in different grades and sizes for various projects. They follow international standards for high-quality and reliability.

| Grade | Specification | Application |

| API 5L X52 | LSAW, 24″ OD, 0.5″ WT | Oil and Gas Pipelines |

| API 5L X60 | LSAW, 36″ OD, 0.75″ WT | High-Pressure Pipelines |

Export to Sheets

Quality Assurance and Testing Methods

Our LSAW pipes go through strict testing. This includes hydrostatic and non-destructive testing (NDT). It ensures the pipes are safe and perform well.

Pros of Our LSAW Pipes

The LSAW pipes from ALLLAND STEEL have many benefits:

Strength and Durability: Made with strong steel, these pipes can handle tough environments. These pipes are built to last, so you don’t need to replace them often.

Precision and Reliability: The making process ensures exact sizes and reliable use. Our LSAW pipes are made to high standards, for consistent quality.

Coating Options: There are many coatings to protect the pipes from rust. Coatings like epoxy or polyurethane can make the pipes even more durable.

Cons and Limitations

While Our LSAW pipes have many advantages, there are some downsides:

Cost Considerations: LSAW pipes might cost more than other types at first. The price of LSAW pipes depends on material costs and how complex they are to make.

Transportation Challenges: LSAW pipes are big and heavy, making them hard to move. Special gear is needed to safely and efficiently move LSAW pipes.

Application Restrictions: LSAW pipes might not fit all uses because of their size and material. It’s important to talk to experts to see if LSAW pipes are right for your project.

Applications and Recommendations

Our LSAW steel pipes are versatile and can be used in various applications. Their durability and resistance to corrosion make them an ideal choice for demanding industries.

Ideal Use Cases

Our LSAW steel pipes are suitable for a range of applications, including:

Oil and Gas Industry Applications: They are used in onshore and offshore pipelines for transporting oil and gas. This is because they can handle high pressures well.

Water Transmission Projects: LSAW pipes are ideal for water transmission projects. This is because of their durability and resistance to corrosion.

Structural and Construction Uses: They are also used in structural and construction applications, for example, in piling and foundation work.

Who Should Choose Our LSAW Pipes

Companies involved in oil and gas exploration, water transmission projects, and large-scale construction projects should consider Our LSAW pipes. These pipes offer a reliable solution for projects that require high-quality, durable piping.

Specifications and Customization Options

ALLLAND STEEL offers various specifications and customization options to meet the specific needs of their clients.

Contact Details and Customer Service

For more information, customers can reach out to Our customer service team. They are available to provide support and guidance throughout the ordering process.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of LSAW steel pipes? LSAW pipes offer superior strength and durability due to their longitudinal seam welded by submerged arc welding, making them ideal for high-pressure applications. This highlights the LSAW pipe meaning.

Q2: Can ALLLAND STEEL customize LSAW pipes? Yes, ALLLAND STEEL provides various grades, sizes, and coating options tailored to your project needs.

Q3: Are LSAW pipes suitable for offshore pipelines? Absolutely. Their strength and corrosion resistance make them perfect for both onshore and offshore oil and gas pipelines. This is an example of LSAW pipe usage.

Q4: How does ALLLAND STEEL ensure pipe quality? All pipes undergo strict hydrostatic and non-destructive testing to guarantee safety and performance.

How to Order Our LSAW Pipes

To place an order or request a quote, contact Our Company directly:

Customization options are available to meet specific project requirements. Our customer service team is ready to assist you throughout the ordering process.

Conclusion

Our Company provides top-notch LSAW steel pipes for different industrial needs. Their pipes are durable and resistant to corrosion. This makes them perfect for many uses. Their manufacturing process and quality checks ensure the pipes meet standards. Customers can pick the right pipes for their projects from a wide range of options. LSAW pipes are great for high-pressure and high-temperature jobs. This is why they’re popular in oil and gas, construction, and more. Choosing Our LSAW pipes means getting their expertise and support. In short, Our Company’s LSAW steel pipes are a solid choice for many industrial needs. They offer quality, durability, and performance all in one. Our Company is a reliable LSAW pipe manufacturer. As an LSAW steel pipe factory , they produce LSAW welded steel pipe and LSAW carbon steel pipe.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

- Carbon Steel Floating Pipeline Systems: Innovative Applications of LSAW/SSAW Steel Pipes in Marine Engineering

- LSAW Steel Pipe: UOE vs JCOE Process | Allland steel pipe

- Onshore Pipeline: A Complete Selection Guide

- 3PE Pipe Coatings: A Guide to Protection, Standards&Applications