3PE Pipe Coatings: A Guide to Protection, Standards&Applications

In the field of pipeline infrastructure, corrosion is one of the biggest factors threatening life and safety. This is where advanced solutions come into play, such as anti-corrosion 3 PE steel pipes and 3 LPE pipeline coatings, setting new benchmarks for durability and reliability. Compliant with international standards such as DIN 30670, these coatings address critical industry pain points while delivering long-term value.

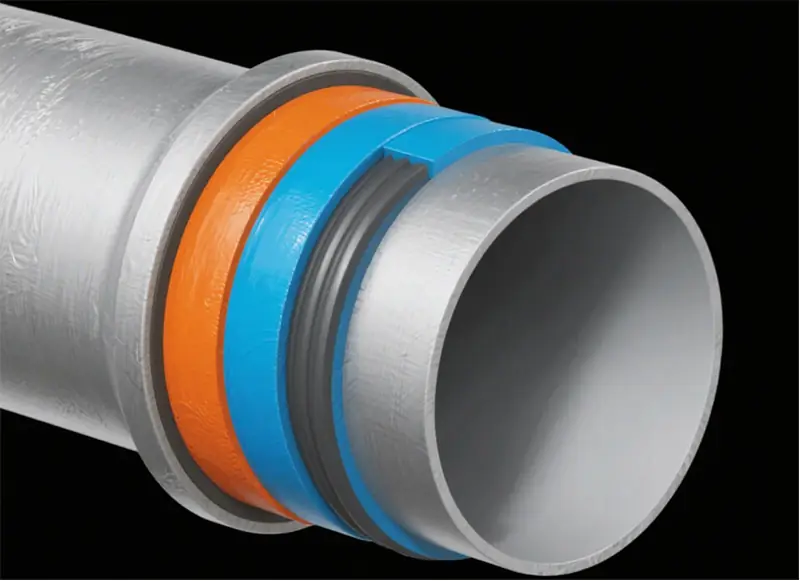

What are the coating of 3 PE steel pipe and 3LPE pipe?

A 3 PE steel pipe is coated with three layers, which has strong anticorrosion ability. The first layer (epoxy powder, FBE) is adhered to steel, blocking moisture and corrosive materials. The second layer (copolymer adhesive) adheres FBE to the outermost layer of high-density polyethylene (HDPE), which can resist mechanical damage, impact and wear.

The 3 LPE pipeline coating technology needs strict quality control, and each layer needs accurate thickness and uniformity. The system enhances the corrosion resistance and prolongs the service life of the pipeline, making it cost-effective for a long time.

Unique Advantages of 3 PE/3 LPE Pipe Coating

Compared with the traditional single-layer coatings such as FBE (molten epoxy resin), 3 PE/3 LPE systems provides unparalleled performance. Tests shows that compared with FBE alone, the impact resistance (≥ 10 j at-20) and wear resistance of the 3PE coating are improved by 3 times.

1. Excellent Mechanical Protection

The HDPE outer layer of 3 PE steel pipe provides physical protection that single layer FBE cann’t compare with. Tests show that 3 PE coatings provide 3 x higher impact resistance (≥ 10 J at -20°C) and abrasion resistance than FBE alone. In contrast, a damaged single-layer FBE coating is directly exposed to the outside of the steel pipe, resulting in rapid rust.

2. Redundancy of corrosion protection.

3 PE coating to create a “chemical+physical” dual protection system. If the outer HDPE layer is slightly damaged (e.g. Scratches during installation), and the internal FBE layer remains intact, which continues to prevent corrosion. On the contrary, a damaged single layer FBE coating will directly expose the steel pipe, leading to rapid rust. This redundancy greatly reduces the risks of leakage and the need for maintenance.

3. Long term cost Efficiency

While 3 PE steel pipe has a slightly higher initial cost than FBE, its design life is 1.5–2 x longer (often exceeding 30 years). In addition, they can work reliably across a wide temperature range: from-40 C to 80 C, which makes them suitable for both cold climates (e.g. For example, a Middle Eastern client previously used single-layer asphalt coatings for an onshore oil pipeline—these failed within 5 years due to high-salinity, humid soil, causing costly leaks and repairs. After switching to 3 PE steel pipe in accordance with DIN 30670 standard, the pipeline runs stably and the long-term operation costs is greatly reduced.

3 PE coatings boast strong adhesion to steel, with a peel strength of ≥ 15 N/cm—well above industry minimums. In order to ensure consistency and quality, 3 PE steel pipe and 3 LPE pipe coating must adhere to strict international standards. The most widely recognized standard is DIN 30670-2012, which specifies requirements for polyethylene coating on buried and above-ground steel pipes.

4. Product Specifications and compliance standards.

In order to ensure consistency and quality, 3 PE steel pipe and 3 LPE pipe coating must adhere to strict international standards. The most widely recognized standard is DIN 30670-2012, which specifies requirements for polyethylene coating on buried and above-ground steel pipes.

In terms of physical specifications, the total coating thickness of 3 PE steel pipe is between 1.8 mm and 4.0 mm according to the different diameter.

Conclusion

For infrastructure projects that need long-term corrosion protection, mechanical durability and cost-effectiveness, the coating of 3 PE steel pipe and 3 LPE pipe coating is unparalleled. These coatings comply with DIN 30670 and other standards, and solve the pain points in the real world, from asphalt layer failure to high maintenance costs, while providing a design life of more than 30 years. Whether it is oil pipelines in harsh deserts or water supply systems in a wet area, 3 PE technology can ensure the safe, reliable and economical operation of pipelines. By investing in 3 PE steel pipe, engineers and project managers can protect their infrastructure and avoid costly consequences caused by corrosion.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.