What Are Grooved Pipe Fittings and Couplings?

Brief introduction

You are managing an important project-a fire fighting system or a factory pipeline. The construction period is very tight and labor costs is very high. Traditional steel pipe welding speed is slow, the cost is high, the special labor force is needed, and there is a major fire hazard. Threading is also a labor-intensive process that can weaken the pipe wall integrity, creating potential failure points.

Nowadays, the widely used modern efficient solution is the grooved connection system. It can increase the installation speed by five times, significantly reducing the total installation cost, and enhance the safety of the work site (Source: Industry estimates of major machinery contractors). This comprehensive guide explains the working principle of grooved Fittings and joints, their different types, and why they are the most cost-effective and wise purchase choice for modern pipeline engineering, even when welding with standard steel pipe.

What is a Grooved Joining System?

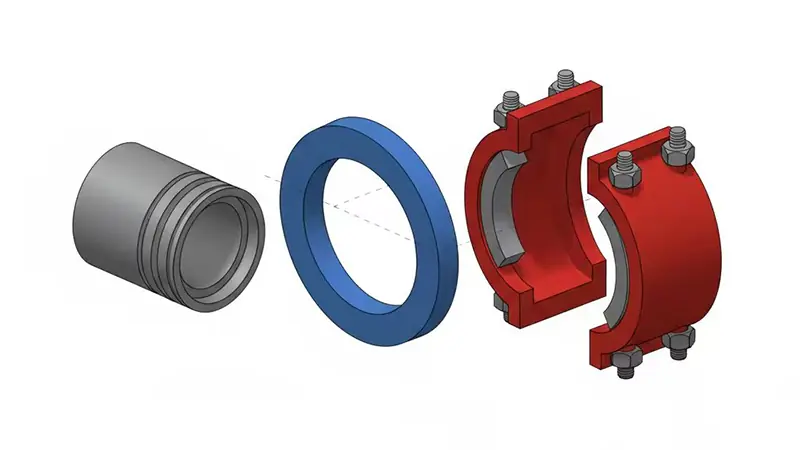

Grooved Fittings is a mechanical method to connect pipelines, which is famous for its simplicity, reliability and easy installation. It uses three key components, making it an ideal choice for leading steel pipe manufacturers to produce steel pipe. The integrity of the final joint depends largely on the quality of the foundation steel pipe, so choosing a reputable supplier is very important for long-term performance and system reliability.

1. Grooved pipeline

Make an accurate groove near the end of the pipeline by rolling or cutting. This kind of preparation is quick and can be completed efficiently on site.

2. The Gasket

An elastomer ring that creates a 100% pressure-tight seal. Under pressure, the seal will become closer and more effective.

3. The Coupling

A two-piece housing locked in the grooves. Tightening its bolts secures the steel pipes and compresses the gasket securely.

The highlight of this design lies in the clear division of responsibilities: the washer is responsible for sealing, while the coupling provides complete structural strength.

The Quantifiable Advantage – Why Buy Grooved?

The smartest metric for evaluation is the Total Installed Cost (TIC), which encompasses materials, labor, and ancillary expenses, not just the upfront fitting price. The following comparison table illustrates the obvious advantages of the steel pipe’s groove system over the traditional welding and threading methods in terms of operation and finance.

| Feature | Cost Factor Grooved System | Welded System | Threaded System |

| Installation Speed | Fastest (3-5 x Faster) | Slowest | Slow |

| Total Installation Cost | Lowest | Highest (skilled labor) | Medium |

| Upfront Fitting Price | Medium | Low | Low |

| Fire/Hot Work Risk | None (Cold Work) | High | Low |

| Flexibility for Modifications | Extremely Easy | Very Difficult | Difficult |

Source: Comparative analysis based on data of Mechanical Contract Association.

Value Proposition:

Although the price of a single coupling may be higher than that of welded elbow, it saves a lot of labor because it does not require a high-paid certified welder to assemble it. This remarkable efficiency, combined with the complete cancellation of the hot work permits, can reduce the total project cost by more than 30% (Source: labor efficiency and project management report industry case study). This is a strategic and reasonable investment for any project.

How to choose: rigid couplings and flexible couplings

Choosing the correct model is very important for system performance and long-term reliability. This decision should be based on specific engineering requirements, because the price difference between different types is usually small. Consulting your supplier at the purchasing stage is the best practice to ensure the best choice for your specific application needs.

Rigid couplings

Create a fixed and immovable connection, which is similar in function to a steel pipe’s welded connection. It is most suitable for applications that require solid support, such as vertical risers and long straight pipelines that do not need to be moved.

Flexible couplings

The degree of control that allows angular and linear movement. It is most suitable for earthquake zones, areas with significant thermal expansion, and absorbing vibration of pumps and compressors.

Summary

In a word, grooved piping systems has faster installation speed, higher safety and the lowest total installation cost. They represent the modern standard for efficient and reliable piping infrastructure, providing long-term value and operational flexibility for facility managers. When you decide to purchase grooved Fittings, you are making a strategic investment in the future efficiency and maintainability of your facility infrastructure.

Are you ready to see the concrete savings of the project? Please contact us immediately to get detailed quotation for specific projects and a comprehensive cost-benefit analysis tailored to your needs.

FAQ

Question 1: What is the main price difference between grooved and traditional accessories?

Answer: The initial purchase price of groove coupling is usually higher than that of basic welding fitting. However, this is offset by drastically reduced labor hours, leading to a significantly lower Total Installed Cost for the overall project, delivering better value.

Question 2: Is the strength of grooved pipe fittings the same as that of welded joints?

Answer: Yes, for their rated applications. High-quality rigid grooved couplings are designed to meet or exceed the pressure ratings of the pipe itself in most standard applications, offering comparable reliability to welding, ensuring the integrity of the whole system.

Question 3: Where can I buy the best grooved pipe fittings?

Answer: the best strategy is to buy from mature professional suppliers and steel pipe manufacturers with comprehensive certifications (UL, FM, ISO). Companies like Allland can ensure that you get reliable, high-quality products, expert guidance and comprehensive technical support to help your project succeed.

Share:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.

Related Articles

ASTM A53 vs. API 5L: A Guide to Selection and Application

Introduction:Technology differences determine success or failure, and selection needs to be “precise”

Steel Density Analysis: Core Differences between Mild and Medium Carbon Steels and Industrial Applications

3LPE coated steel pipe: a solid barrier in the field of industrial corrosion protection

3LPP coated pipe: anti-corrosion guard in high temperature and high pressure environment

FBE steel pipe: the technological armor of the steel defense line

HOT TAGS

latest posts

- ASTM A53 vs. API 5L: A Guide to Selection and Application

- Cracking the Code: What Makes SSAW Spiral Steel Pipes the Engineer’s Top Pick Worldwide

- What is ASTM A252 pipe? Engineering basic solution.

- A Concise Guide to EN 10217: European Standard for Pressure Welded Tubes

- The Hydrostatic Test: Why It’s the Final Defense for API 5L Pipe Integrity