HOT PRODUCTS TAGS

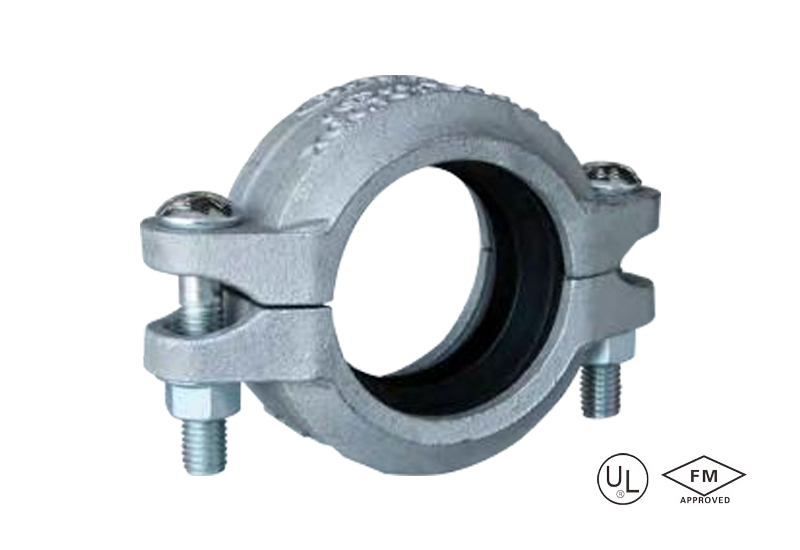

Flexible Grooved Coupling

·Standard: ANSI / UL 213 UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt &: nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 24″

description

Flexible grooved coupling is a flexible pipe joint with a grooved connection structure. It connects and joints pipes through grooves, allowing for a certain relative displacement between pipes to compensate for deformation or absorb vibration

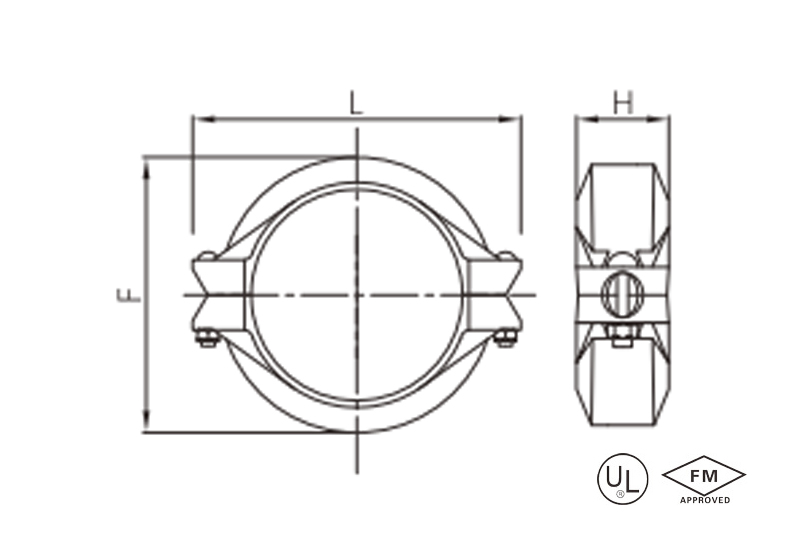

Specification

Available size

| Size | Dimension (mm) | Bolting (n x bolt size) | |||||

| Inch | DN | mm | F | L | H | ANSI | EN |

| 1″ | 25 | 33.7 | 55 | 92 | 42 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 1-1/4″ | 32 | 42.4 | 65 | 104 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 1-1/2″ | 40 | 48.3 | 70 | 110 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2″ | 50 | 60.3 | 83 | 125 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ | 65 | 73.0 | 96 | 143 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ | 65 | 76.1 | 100 | 145 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 3″ | 80 | 88.9 | 115 | 160 | 45 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ | 100 | 114.3 | 145 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 5″ | 125 | 139.7 | 169 | 230 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 5″ | 125 | 141.3 | 170 | 232 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ | 150 | 165.1 | 196 | 260 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ | 150 | 168.3 | 200 | 265 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 8″ | 200 | 219.1 | 258 | 350 | 60 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

| 10″ | 250 | 273.0 | 337 | 406 | 65 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

| 12″ | 300 | 323.9 | 378 | 465 | 65 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

| 16″ | 400 | 406.4 | 468 | 575 | 72 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 18″ | 450 | 457.2 | 508 | 608 | 78 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 20″ | 500 | 508.0 | 563 | 660 | 78 | 4 – 7/8″ × 140 | 4 – M22 × 140 |

| 24″ | 600 | 609.6 | 668 | 772 | 78 | 4 – 1″ × 140 | 4 – M24 × 140 |

application

- Flexible pipe connections: Used in pipe systems that require the absorption of vibrations, thermal expansion and contraction, or minor displacement, such as air conditioning water pipes, fire protection networks, and inlet and outlet pipes of pump rooms.

- Vibration reduction and noise control: Installed near pumps, compressors, and other equipment to reduce the transmission of vibrations, protect the equipment, and lower noise levels.

- Adaptable to complex environments: Suitable for pipes crossing building expansion joints and settlement areas to prevent pipe failure due to foundation deformation.

- Versatile compatibility: Compatible with various pipe materials (such as steel pipes, ductile iron, etc.), with pipe diameters ranging from 1 inch to 24 inches (DN25-DN600).

advantages

- Auto re-displace compensation: Automatically tunes the minor displacement caused by temperature and vibration, resolves stress concentration, prolongs pipe life.

- Ultra-efficient vibration isolation: The use of built-in rubber seals ensure shocks only, while the other devices are well protected from harmful effects.

- Convenient installation: does not require welding, but also without any precise alignment ensures the two bolts to complete the installation, compared with other power devices can save labor over 60%.

- Seal Type: Can be used for sealing a water, oil or gas type of media as it ensures zero leakages during high-pressure circumstances (funding up to 300-500 psi pressure).

- Maintenance is simple: components can be uninstalled and replaced without the need to cut the pipeline, which means almost no downtime.

Long Life: Ductile iron body, painted with red color or hot-dip galvanizing (optional), waterproof and dustproof seals, not easy to age and corrode, life of up to 25 years.

packing

- Standard Protection:

- Each fitting is individually packaged in a paper box with a desiccant bag and installation instructions included.

- The outer box indicates the product type, dimensions, and pressure rating.

- Strengthened for large sizes:

- Piping 8 inches and above are packaged in custom wooden crates with anti-vibration foam to ensure zero damage during transportation.

- Bulk Transportation:

- Stacked on pallets and secured with stretch wrap, meeting export standards for sea and land transport.

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

1″ | 25 | 33.7 | 55 | 92 | 42 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

1-1/4″ | 32 | 42.4 | 65 | 104 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

1-1/2″ | 40 | 48.3 | 70 | 110 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

2″ | 50 | 60.3 | 83 | 125 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

2-1/2″ | 65 | 73.0 | 96 | 143 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

2-1/2″ | 65 | 76.1 | 100 | 145 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

3″ | 80 | 88.9 | 115 | 160 | 45 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

4″ | 100 | 114.3 | 145 | 198 | 50 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

5″ | 125 | 139.7 | 169 | 230 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

5″ | 125 | 141.3 | 170 | 232 | 51 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

6″ | 150 | 165.1 | 196 | 260 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

6″ | 150 | 168.3 | 200 | 265 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

8″ | 200 | 219.1 | 258 | 350 | 60 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

10″ | 250 | 273.0 | 337 | 406 | 65 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

12″ | 300 | 323.9 | 378 | 465 | 65 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

16″ | 400 | 406.4 | 468 | 575 | 72 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

18″ | 450 | 457.2 | 508 | 608 | 78 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

20″ | 500 | 508.0 | 563 | 660 | 78 | 4 – 7/8″ × 140 | 4 – M22 × 140 |

24″ | 600 | 609.6 | 668 | 772 | 78 | 4 – 1″ × 140 | 4 – M24 × 140 |

- Flexible pipe connections: Used in pipe systems that require the absorption of vibrations, thermal expansion and contraction, or minor displacement, such as air conditioning water pipes, fire protection networks, and inlet and outlet pipes of pump rooms.

- Vibration reduction and noise control: Installed near pumps, compressors, and other equipment to reduce the transmission of vibrations, protect the equipment, and lower noise levels.

- Adaptable to complex environments: Suitable for pipes crossing building expansion joints and settlement areas to prevent pipe failure due to foundation deformation.

- Versatile compatibility: Compatible with various pipe materials (such as steel pipes, ductile iron, etc.), with pipe diameters ranging from 1 inch to 24 inches (DN25-DN600).

- Auto re-displace compensation: Automatically tunes the minor displacement caused by temperature and vibration, resolves stress concentration, prolongs pipe life.

- Ultra-efficient vibration isolation: The use of built-in rubber seals ensure shocks only, while the other devices are well protected from harmful effects.

- Convenient installation: does not require welding, but also without any precise alignment ensures the two bolts to complete the installation, compared with other power devices can save labor over 60%.

- Seal Type: Can be used for sealing a water, oil or gas type of media as it ensures zero leakages during high-pressure circumstances (funding up to 300-500 psi pressure).

- Maintenance is simple: components can be uninstalled and replaced without the need to cut the pipeline, which means almost no downtime.

Long Life: Ductile iron body, painted with red color or hot-dip galvanizing (optional), waterproof and dustproof seals, not easy to age and corrode, life of up to 25 years.

- Standard Protection:

- Each fitting is individually packaged in a paper box with a desiccant bag and installation instructions included.

- The outer box indicates the product type, dimensions, and pressure rating.

- Strengthened for large sizes:

- Piping 8 inches and above are packaged in custom wooden crates with anti-vibration foam to ensure zero damage during transportation.

- Bulk Transportation:

- Stacked on pallets and secured with stretch wrap, meeting export standards for sea and land transport.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.