HOT PRODUCTS TAGS

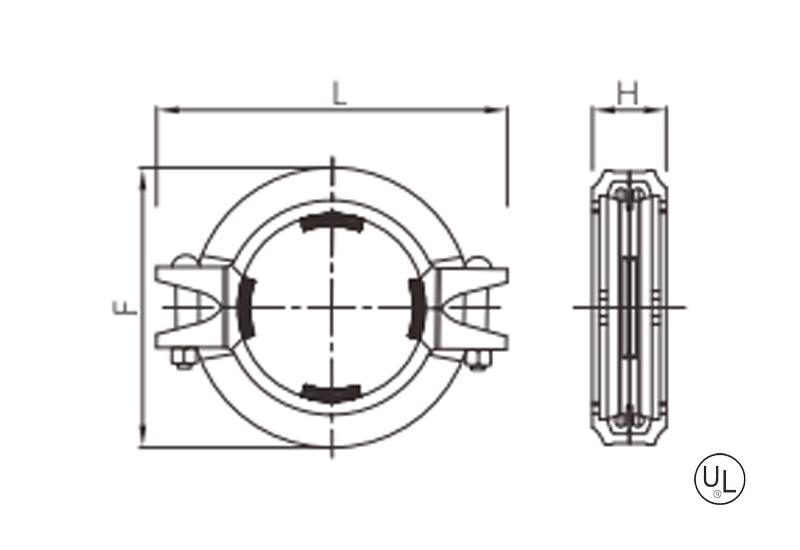

Quick flexible grooved coupling

·Standard: ANSI / UL 213 UL

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4″ × 8″

description

Quick flexible grooved coupling is a quick-installation type flexible pipe joint with a grooved connection structure, allowing for a certain relative displacement between pipes to compensate for deformation or absorb vibration

Specification

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

1-1/4″ | 32 | 42.4 | 65 | 108 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

1-1/2″ | 40 | 48.3 | 72 | 115 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2″ | 50 | 60.3 | 85 | 126 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 73 | 97 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 76.1 | 100 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

3″ | 80 | 88.9 | 112 | 160 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 63 |

4″ | 100 | 114.3 | 138 | 194 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 139.7 | 168 | 226 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 141.3 | 170 | 228 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

6″ | 150 | 165.1 | 191 | 249 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

6″ | 150 | 168.3 | 198 | 257 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

8″ | 200 | 219.1 | 252 | 323 | 61 | 2 – 5/8″ × 85 | 2 – M16 × 89 |

application

- Emergency Repair + Vibration Damping Requirements: Tailored for rapid fixes and vibration reduction needs such as pump repairs and immediate air conditioning pipe maintenance, balancing the need for speed with system stability.

- Dynamic pipeline systems are often seen in service where there is considerable thermal expansion and contraction, or equipment vibration (e.g. industrial power pipelines, fire protection networks) that needs to be compensated for preventing rupture.

- Limited Space Operations: Fast installation of facilities in narrow spaces like trenches, high-altitude regions and equipment gaps with simple tools.

- Zero-Leak Areas: Pipe connections in critical zero-leak applications like hospitals and labs where safety is essential.

advantages

1. 8x faster to install – 2 bolts tightened compared to the traditional method, using patented snap-fit design for 80% time-savings against conventional methods

2. Intelligent vibration damping: The flexible structure absorbs the vibrations and movements of the pipe automatically and prevents equipment from being damaged.

3. Superb sealing assurance: Rubber gaskets (EPDM) which are of high-quality guarantee no leakages for water, oil or gas media.

4. Single Person Operation: With its lightweight design, it does not require any tools as well as another individual to assist in installing the solar panels even at high- or narrow-range locations;

5. Corrosion Resistant: The ductile iron body is protected with an anti-corrosive coating making it safe for humid and underground use.

6. How it Reuses for Zero-Cost: Disassemble and reassemble fast, can be reset during maintenance with no costs of spare parts.

packing

- Ready-to-use portable package:

- Each item is individually packaged in a hard box (with built-in shock-absorbing padding) and comes with illustrated installation instructions. Installation can be completed in 5 minutes upon opening the box.

- Outer box clearly labeled: Quick-connect flexible joint, 4 inches, specifically designed for emergency repairs and vibration reduction.

- Protection of moving parts:

- Rubber gaskets stored in separate sealed bags to prevent deformation from compression; bolts pre-installed to prevent loss.

- Efficient bulk transportation:

- Compact paper boxes stacked on reinforced pallets, secured with stretch film and corner protectors, allowing for quick shipment of entire pallets when needed.

Available size

Size | Dimension (mm) | Bolting (n x bolt size) | |||||

Inch | DN | mm | F | L | H | ANSI | EN |

1-1/4″ | 32 | 42.4 | 65 | 108 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

1-1/2″ | 40 | 48.3 | 72 | 115 | 47 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2″ | 50 | 60.3 | 85 | 126 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 73 | 97 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

2-1/2″ | 65 | 76.1 | 100 | 140 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 57 |

3″ | 80 | 88.9 | 112 | 160 | 48 | 2 – 3/8″ × 60 | 2 – M10 × 63 |

4″ | 100 | 114.3 | 138 | 194 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 139.7 | 168 | 226 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

5″ | 125 | 141.3 | 170 | 228 | 50 | 2 – 1/2″ × 65 | 2 – M12 × 70 |

6″ | 150 | 165.1 | 191 | 249 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

6″ | 150 | 168.3 | 198 | 257 | 51 | 2 – 1/2″ × 80 | 2 – M12 × 82 |

8″ | 200 | 219.1 | 252 | 323 | 61 | 2 – 5/8″ × 85 | 2 – M16 × 89 |

- Emergency Repair + Vibration Damping Requirements: Tailored for rapid fixes and vibration reduction needs such as pump repairs and immediate air conditioning pipe maintenance, balancing the need for speed with system stability.

- Dynamic pipeline systems are often seen in service where there is considerable thermal expansion and contraction, or equipment vibration (e.g. industrial power pipelines, fire protection networks) that needs to be compensated for preventing rupture.

- Limited Space Operations: Fast installation of facilities in narrow spaces like trenches, high-altitude regions and equipment gaps with simple tools.

- Zero-Leak Areas: Pipe connections in critical zero-leak applications like hospitals and labs where safety is essential.

1. 8x faster to install – 2 bolts tightened compared to the traditional method, using patented snap-fit design for 80% time-savings against conventional methods

2. Intelligent vibration damping: The flexible structure absorbs the vibrations and movements of the pipe automatically and prevents equipment from being damaged.

3. Superb sealing assurance: Rubber gaskets (EPDM) which are of high-quality guarantee no leakages for water, oil or gas media.

4. Single Person Operation: With its lightweight design, it does not require any tools as well as another individual to assist in installing the solar panels even at high- or narrow-range locations;

5. Corrosion Resistant: The ductile iron body is protected with an anti-corrosive coating making it safe for humid and underground use.

6. How it Reuses for Zero-Cost: Disassemble and reassemble fast, can be reset during maintenance with no costs of spare parts.

- Ready-to-use portable package:

- Each item is individually packaged in a hard box (with built-in shock-absorbing padding) and comes with illustrated installation instructions. Installation can be completed in 5 minutes upon opening the box.

- Outer box clearly labeled: Quick-connect flexible joint, 4 inches, specifically designed for emergency repairs and vibration reduction.

- Protection of moving parts:

- Rubber gaskets stored in separate sealed bags to prevent deformation from compression; bolts pre-installed to prevent loss.

- Efficient bulk transportation:

- Compact paper boxes stacked on reinforced pallets, secured with stretch film and corner protectors, allowing for quick shipment of entire pallets when needed.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.