HOT PRODUCTS TAGS

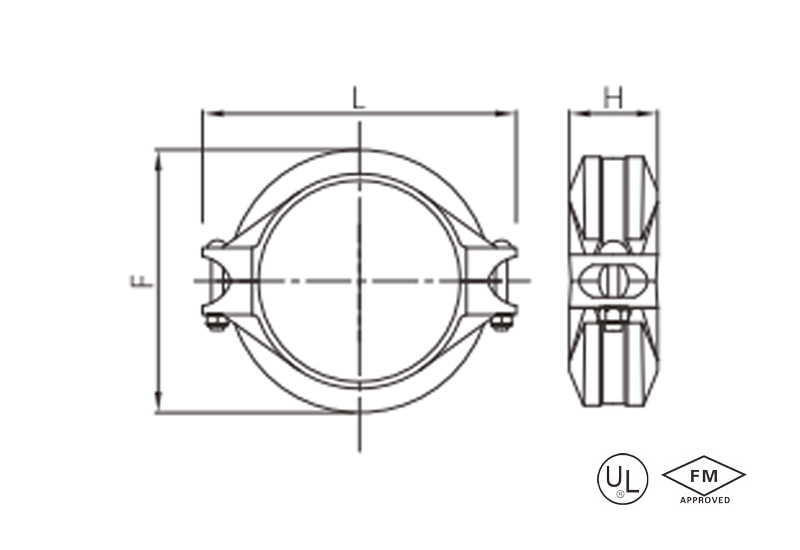

Rigid Grooved Coupling

Standard: ANSI/UL 213 UL / FM

Material: Ductile iron ASTM A536, 65-45-12

Bolt & nut: Carbon steel

Gasket: EPDM, nitrile, silicone rubber, etc

Rated pressure: 300 -500 psi

Surface: Red painting / hot dip galvanized

Size range: 1″ – 24″

description

Rigid grooved coupling is a rigid pipe joint with a grooved connection structure. It rigorously connects pipes through the grooved connection method, restricting the relative displacement between pipes

Specification

Available size

| Size | Dimension (mm) | Bolting (n x bolt size) | |||||

| Inch | DN | mm | F | L | H | ANSI | EN |

| 1″ | 25 | 33.7 | 59 | 100 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 1-1/4″ | 32 | 42.4 | 66 | 110 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 1-1/2″ | 40 | 48.3 | 72 | 115 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2″ | 50 | 60.3 | 85 | 131 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ | 65 | 73.0 | 98 | 145 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ | 65 | 76.1 | 101 | 147 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 3″ | 80 | 88.9 | 115 | 170 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ | 100 | 114.3 | 146 | 200 | 52 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 5″ | 125 | 139.7 | 170 | 238 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 5″ | 125 | 141.3 | 172 | 237 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ | 150 | 165.1 | 198 | 266 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ | 150 | 168.3 | 202 | 270 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 8″ | 200 | 219.1 | 260 | 346 | 62 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

| 10″ | 250 | 273.0 | 327 | 420 | 63 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

| 12″ | 300 | 323.9 | 378 | 466 | 63 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

| 14″ | 350 | 355.6 | 415 | 510 | 72 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 16″ | 400 | 406.4 | 468 | 575 | 72 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 18″ | 450 | 457.2 | 508 | 608 | 78 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 20″ | 500 | 508.0 | 563 | 660 | 78 | 4 – 7/8″ × 140 | 4 – M22 × 140 |

| 24″ | 600 | 609.6 | 668 | 772 | 78 | 4 – 1″ × 140 | 4 – M24 × 140 |

application

- It is suitable for industrial piping systems that require rigid connections and prohibit pipeline displacement, such as fire water pipes, air conditioning cold water/hot water pipelines, industrial process pipelines, etc.

- Widely used in scenarios requiring ANSI/UL 213 UL/FM certification (such as fire protection systems), meeting strict safety standards.

- Suitable for connecting grooved end pipes of ductile iron, carbon steel, stainless steel, etc., with a pipe diameter range of 1″-24″ (DN25-DN600).

- Ideal choice: near fixed brackets, at pipe turns, and other critical nodes where pipe expansion/vibration needs to be completely limited.

advantages

- No displacement structure: The pipeline has zero axial and radial reaction force after being mechanically locked to the groove, and it will not move under all conditions of work to ensure the system rigidity.

- Easy assembly: Welding or flange connections are no longer necessary for the connection, only tightening of bolts is needed, with installation time saved more than 50%.

- Seismic & impact resistant: Ductile iron body (ASTM A536) with carbon steel bolts ensures structural strength to withstand water hammer and other external loads.

- Gaskets: EPDM/NBR rubber gaskets can be used for water/oil/gas and seal reliably there is no leakage between 300–500 psi.

- Practical for maintenance: Classic designed latches are helpful to dismantle, which is convenient to do a localized repair without damaging the original pipeline structure.

- Corrosion resistant and durable, with hot-dip galvanized or red paint surface requires no maintenance up to 30 years.

packing

- Standard Export Packaging:

- Individual cardboard box/plastic bag protection, including material certificate and installation guide.

- External labeling on carton includes dimensions, pressure rating, and moisture-proof 标识 (e.g., Rigid Coupling, 6″, 500 psi).

- Custom wooden box with anti-vibration padding for protection of components DN300 (12″) and above to avoid transportation impact.

- Bulk transportation: palletized stacking (no more than 1,500 kg per pallet), wrapped with stretch film, conforming to international freight standards.

- Standard Export Packaging:

Available size

| Size | Dimension (mm) | Bolting (n x bolt size) | |||||

| Inch | DN | mm | F | L | H | ANSI | EN |

| 1″ | 25 | 33.7 | 59 | 100 | 44 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 1-1/4″ | 32 | 42.4 | 66 | 110 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 1-1/2″ | 40 | 48.3 | 72 | 115 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2″ | 50 | 60.3 | 85 | 131 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ | 65 | 73.0 | 98 | 145 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 2-1/2″ | 65 | 76.1 | 101 | 147 | 45 | 2 – 3/8″ × 55 | 2 – M10 × 57 |

| 3″ | 80 | 88.9 | 115 | 170 | 46 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 4″ | 100 | 114.3 | 146 | 200 | 52 | 2 – 1/2″ × 70 | 2 – M12 × 70 |

| 5″ | 125 | 139.7 | 170 | 238 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 5″ | 125 | 141.3 | 172 | 237 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ | 150 | 165.1 | 198 | 266 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 6″ | 150 | 168.3 | 202 | 270 | 52 | 2 – 5/8″ × 85 | 2 – M16 × 85 |

| 8″ | 200 | 219.1 | 260 | 346 | 62 | 2 – 3/4″ × 115 | 2 – M20 × 115 |

| 10″ | 250 | 273.0 | 327 | 420 | 63 | 2 – 7/8″ × 125 | 2 – M22 × 125 |

| 12″ | 300 | 323.9 | 378 | 466 | 63 | 2 – 7/8″ × 140 | 2 – M22 × 140 |

| 14″ | 350 | 355.6 | 415 | 510 | 72 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 16″ | 400 | 406.4 | 468 | 575 | 72 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 18″ | 450 | 457.2 | 508 | 608 | 78 | 3 – 7/8″ × 140 | 3 – M22 × 140 |

| 20″ | 500 | 508.0 | 563 | 660 | 78 | 4 – 7/8″ × 140 | 4 – M22 × 140 |

| 24″ | 600 | 609.6 | 668 | 772 | 78 | 4 – 1″ × 140 | 4 – M24 × 140 |

- It is suitable for industrial piping systems that require rigid connections and prohibit pipeline displacement, such as fire water pipes, air conditioning cold water/hot water pipelines, industrial process pipelines, etc.

- Widely used in scenarios requiring ANSI/UL 213 UL/FM certification (such as fire protection systems), meeting strict safety standards.

- Suitable for connecting grooved end pipes of ductile iron, carbon steel, stainless steel, etc., with a pipe diameter range of 1″-24″ (DN25-DN600).

- Ideal choice: near fixed brackets, at pipe turns, and other critical nodes where pipe expansion/vibration needs to be completely limited.

- No displacement structure: The pipeline has zero axial and radial reaction force after being mechanically locked to the groove, and it will not move under all conditions of work to ensure the system rigidity.

- Easy assembly: Welding or flange connections are no longer necessary for the connection, only tightening of bolts is needed, with installation time saved more than 50%.

- Seismic & impact resistant: Ductile iron body (ASTM A536) with carbon steel bolts ensures structural strength to withstand water hammer and other external loads.

- Gaskets: EPDM/NBR rubber gaskets can be used for water/oil/gas and seal reliably there is no leakage between 300–500 psi.

- Practical for maintenance: Classic designed latches are helpful to dismantle, which is convenient to do a localized repair without damaging the original pipeline structure.

- Corrosion resistant and durable, with hot-dip galvanized or red paint surface requires no maintenance up to 30 years.

- Standard Export Packaging:

- Individual cardboard box/plastic bag protection, including material certificate and installation guide.

- External labeling on carton includes dimensions, pressure rating, and moisture-proof 标识 (e.g., Rigid Coupling, 6″, 500 psi).

- Custom wooden box with anti-vibration padding for protection of components DN300 (12″) and above to avoid transportation impact.

- Bulk transportation: palletized stacking (no more than 1,500 kg per pallet), wrapped with stretch film, conforming to international freight standards.

- Standard Export Packaging:

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.