HOT PRODUCTS TAGS

Flanged reducing tee

·Standard: ANSI / UL 213C, EN 1092 ISO

·Material: Ductile iron

·Flanged end:

EN 1092-2, PN10 / PN 16 / PN 25,

RF or ANSI B16.1 Class 125,

B16.42 Class 150, FF or RF

·Rated pressure: 300 – 500 psi

·Surface: Red or blue painting

·Size range: 3″ – 24″

description

Flanged reducing tee is a reducing tee fitting with flange connection structure. The three interface sizes are different, and the branch connection of pipelines of different diameters is achieved through flange connection.

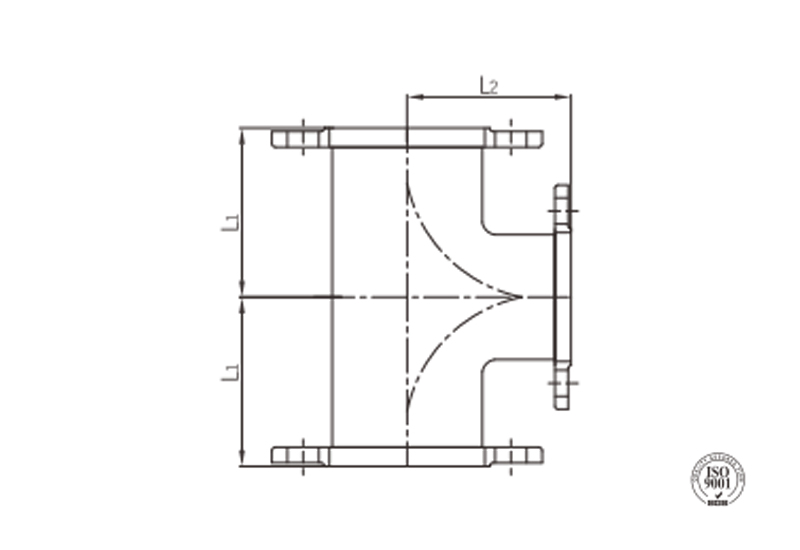

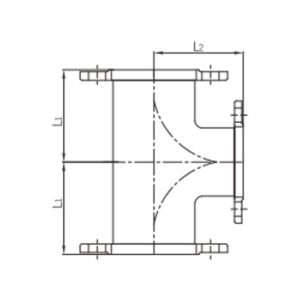

Specification

Available size

Size | Center to end (mm) | |||

Inch | DN | mm | L1 | L2 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 180 | 175 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 220 | 205 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 220 | 210 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 260 | 235 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 260 | 240 |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 260 | 250 |

10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 350 | 275 |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 350 | 300 |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 350 | 325 |

12″ × 4″ | 300 × 100 | 323.9 × 114.3 | 400 | 300 |

12″ × 6″ | 300 × 150 | 323.9 × 165.1 | 400 | 325 |

12″ × 8″ | 300 × 200 | 323.9 × 219.1 | 400 | 350 |

14″ × 4″ | 350 × 100 | 355.6 × 114.3 | 425 | 325 |

14″ × 6″ | 350 × 150 | 355.6 × 165.1 | 425 | 325 |

14″ × 8″ | 350 × 200 | 355.6 × 219.1 | 425 | 325 |

14″ × 12″ | 350 × 300 | 355.6 × 323.9 | 425 | 425 |

16″ × 4″ | 400 × 100 | 406.4 × 114.3 | 450 | 350 |

16″ × 6″ | 400 × 150 | 406.4 × 165.1 | 450 | 350 |

16″ × 8″ | 400 × 200 | 406.4 × 219.1 | 450 | 350 |

16″ × 12″ | 400 × 300 | 406.4 × 323.9 | 450 | 450 |

18″ × 4″ | 450 × 100 | 457.2 × 114.3 | 475 | 375 |

18″ × 6″ | 450 × 150 | 457.2 × 165.1 | 475 | 375 |

18″ × 8″ | 450 × 200 | 457.2 × 219.1 | 475 | 375 |

18″ × 12″ | 450 × 300 | 457.2 × 323.9 | 475 | 475 |

18″ × 16″ | 450 × 400 | 457.2 × 406.4 | 475 | 475 |

20″ × 4″ | 500 × 100 | 508.0 × 114.3 | 500 | 400 |

20″ × 6″ | 500 × 150 | 508.0 × 165.1 | 500 | 400 |

20″ × 8″ | 500 × 200 | 508.0 × 219.1 | 500 | 400 |

20″ × 12″ | 500 × 300 | 508.0 × 323.9 | 500 | 500 |

20″ × 16″ | 500 × 400 | 508.0 × 406.4 | 500 | 500 |

24″ × 6″ | 600 × 150 | 609.6 × 165.1 | 550 | 450 |

24″ × 8″ | 600 × 200 | 609.6 × 219.1 | 550 | 450 |

24″ × 12″ | 600 × 300 | 609.6 × 323.9 | 550 | 550 |

24″ × 16″ | 600 × 400 | 609.6 × 406.4 | 550 | 550 |

application

- Industrial pipeline transition center: Especially in the case of high pressure system (piping and power plants, petrochemical additional) branch pipe diameter required for small and not to change the direction of flow at the same time is used to connect the main tubing.

- Integration key node for equipment: Compatible with flanged interface equipment such as pumps and valves, simplifying connection of diverse pipe diameters and directly with equipment.

- Major rehabilitation of system: for energy, water treatment and other field core pipeline expansion projects (up to 24″ in diameter).

advantages

1. High Pressure Compatibility: Cast one-piece ductile iron, ANSI/EN/ISO certified rated to 300-500 psi with a high resistance to water hammer and pressure shocks.

2. Advanced mismatch adaptation: three-port diameter difference design, no turbulence energy loss into the tube cross-section, to improve the efficiency of the entire system;

3. Flange compatibility worldwide:American standard: ANSI Class 150 (RF/FF). European Standard: EN PN10/16/25 (RF). Able to serve project needs across regions

4. Corrosion protection: Red/blue epoxy coerce with excellent chemical corrosion resistance, made outdoor life much longer.

5. Full size combination to meet industrial level raw water transition requirements:4”×3”to 24”×16”(DN100-DN600).

packing

- Flange Face Triple Protection:

- Sealing surface covered with scratch-resistant PE film + cushioning cardboard;

- Bolt holes filled with anti-rust wax and fitted with plastic sleeves;

- RF flanges equipped with steel protective rings, FF flanges fitted with wooden protective panels.

- Heavy-Duty Segmented Packaging:

- ≤12″: Single piece secured in a solid wood box lined with moisture-proof paper;

- >12″: Main body and flange ends packaged separately, with laser-etched matching numbers marked on the mating surfaces.

- Smart logistics solution:

- Boxes printed with lifting points, pressure rating warnings, and QR codes (scan to access flange compatibility guidelines);

- Heavy items accompanied by anti-slip pallets and securing anchor points.

Available size

Size | Center to end (mm) | |||

Inch | DN | mm | L1 | L2 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 180 | 175 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 220 | 205 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 220 | 210 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 260 | 235 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 260 | 240 |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 260 | 250 |

10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 350 | 275 |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 350 | 300 |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 350 | 325 |

12″ × 4″ | 300 × 100 | 323.9 × 114.3 | 400 | 300 |

12″ × 6″ | 300 × 150 | 323.9 × 165.1 | 400 | 325 |

12″ × 8″ | 300 × 200 | 323.9 × 219.1 | 400 | 350 |

14″ × 4″ | 350 × 100 | 355.6 × 114.3 | 425 | 325 |

14″ × 6″ | 350 × 150 | 355.6 × 165.1 | 425 | 325 |

14″ × 8″ | 350 × 200 | 355.6 × 219.1 | 425 | 325 |

14″ × 12″ | 350 × 300 | 355.6 × 323.9 | 425 | 425 |

16″ × 4″ | 400 × 100 | 406.4 × 114.3 | 450 | 350 |

16″ × 6″ | 400 × 150 | 406.4 × 165.1 | 450 | 350 |

16″ × 8″ | 400 × 200 | 406.4 × 219.1 | 450 | 350 |

16″ × 12″ | 400 × 300 | 406.4 × 323.9 | 450 | 450 |

18″ × 4″ | 450 × 100 | 457.2 × 114.3 | 475 | 375 |

18″ × 6″ | 450 × 150 | 457.2 × 165.1 | 475 | 375 |

18″ × 8″ | 450 × 200 | 457.2 × 219.1 | 475 | 375 |

18″ × 12″ | 450 × 300 | 457.2 × 323.9 | 475 | 475 |

18″ × 16″ | 450 × 400 | 457.2 × 406.4 | 475 | 475 |

20″ × 4″ | 500 × 100 | 508.0 × 114.3 | 500 | 400 |

20″ × 6″ | 500 × 150 | 508.0 × 165.1 | 500 | 400 |

20″ × 8″ | 500 × 200 | 508.0 × 219.1 | 500 | 400 |

20″ × 12″ | 500 × 300 | 508.0 × 323.9 | 500 | 500 |

20″ × 16″ | 500 × 400 | 508.0 × 406.4 | 500 | 500 |

24″ × 6″ | 600 × 150 | 609.6 × 165.1 | 550 | 450 |

24″ × 8″ | 600 × 200 | 609.6 × 219.1 | 550 | 450 |

24″ × 12″ | 600 × 300 | 609.6 × 323.9 | 550 | 550 |

24″ × 16″ | 600 × 400 | 609.6 × 406.4 | 550 | 550 |

- Industrial pipeline transition center: Especially in the case of high pressure system (piping and power plants, petrochemical additional) branch pipe diameter required for small and not to change the direction of flow at the same time is used to connect the main tubing.

- Integration key node for equipment: Compatible with flanged interface equipment such as pumps and valves, simplifying connection of diverse pipe diameters and directly with equipment.

- Major rehabilitation of system: for energy, water treatment and other field core pipeline expansion projects (up to 24″ in diameter).

1. High Pressure Compatibility: Cast one-piece ductile iron, ANSI/EN/ISO certified rated to 300-500 psi with a high resistance to water hammer and pressure shocks.

2. Advanced mismatch adaptation: three-port diameter difference design, no turbulence energy loss into the tube cross-section, to improve the efficiency of the entire system;

3. Flange compatibility worldwide:American standard: ANSI Class 150 (RF/FF). European Standard: EN PN10/16/25 (RF). Able to serve project needs across regions

4. Corrosion protection: Red/blue epoxy coerce with excellent chemical corrosion resistance, made outdoor life much longer.

5. Full size combination to meet industrial level raw water transition requirements:4”×3”to 24”×16”(DN100-DN600).

- Flange Face Triple Protection:

- Sealing surface covered with scratch-resistant PE film + cushioning cardboard;

- Bolt holes filled with anti-rust wax and fitted with plastic sleeves;

- RF flanges equipped with steel protective rings, FF flanges fitted with wooden protective panels.

- Heavy-Duty Segmented Packaging:

- ≤12″: Single piece secured in a solid wood box lined with moisture-proof paper;

- >12″: Main body and flange ends packaged separately, with laser-etched matching numbers marked on the mating surfaces.

- Smart logistics solution:

- Boxes printed with lifting points, pressure rating warnings, and QR codes (scan to access flange compatibility guidelines);

- Heavy items accompanied by anti-slip pallets and securing anchor points.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.