HOT PRODUCTS TAGS

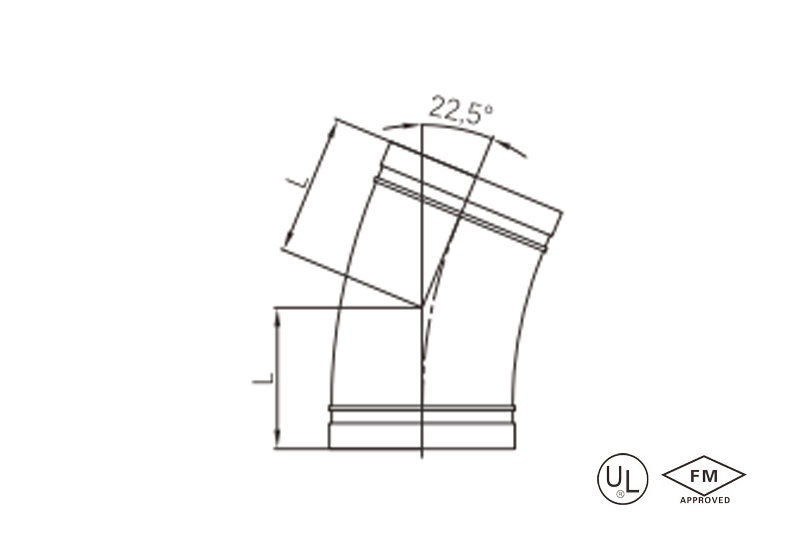

Grooved 22.5° elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Standard radius

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 12″

description

Grooved 22.5° elbow is a 22.5-degree elbow fitting with a grooved connection structure, used to enable the pipeline system to achieve a 22.5-degree turn

Specification

Available size

Size | Center to end | ||

Inch | DN | mm | L(mm) |

1″ | 25 | 33.7 | 41 |

1-1/4″ | 32 | 42.4 | 45 |

1-1/2″ | 40 | 48.3 | 45 |

2″ | 50 | 60.3 | 48 |

2-1/2″ | 65 | 73.0 | 51 |

2-1/2″ | 65 | 76.1 | 51 |

3″ | 80 | 88.9 | 57 |

4″ | 100 | 114.3 | 73 |

5″ | 125 | 139.7 | 73 |

6″ | 150 | 165.1 | 79 |

6″ | 150 | 168.3 | 79 |

8″ | 200 | 219.1 | 98 |

10″ | 250 | 273.0 | 111 |

12″ | 300 | 323.9 | 124 |

application

- Fine-tuning pipe routing: Suitable for scenarios requiring precise turning at small angles (e.g., densely packed chemical plants, precision instrumentation piping systems).

- Long-distance gentle curve system: Mining conveying pipelines, municipal water supply main pipelines, achieved through the combination of multiple 22.5° elbows to create smooth curved piping layouts.

- Vibration reduction and noise reduction design: Suitable for pump inlets/outlets and air compressor pipelines, where small-angle turns minimize fluid impact vibrations and noise.

- Space-constrained areas: Ideal for building interlayers and ship engine rooms, where the design minimizes space requirements for turns.

- Fire protection system upgrades: Replaces 90° elbows to retrofit aging pipelines, improving water flow efficiency without requiring significant adjustments to supports.

advantages

1. Ultra-low resistance: The 22.5° design reduces pressure loss by 40% compared to 45° elbows, significantly reducing energy consumption.

2. Precision fit: The standard bending radius ensures consistent turning and prevents stress concentration in the pipeline.

3. Superior pressure resistance: The ductile iron (ASTM A536) structure enhances deformation resistance by 25% under 500 psi high pressure.

4. Maintenance-free design:Hot-dip galvanized coating with weather resistance ≥20 years (red paint version suitable for indoor dry environments);Grooved joints self-seal, eliminating the need for regular tightening.

5. Plug-and-play: Compatible with any brand of grooved fittings, installation time is only 1/10 of that required for welded elbows

packing

- Differentiated Protection:

- ≤4 inches: 20 pieces per box, sealed with PE bags + corrugated cardboard partitions, moisture-proof and rust-proof;

- >4 inches: individual wooden boxes with top and bottom lids, embedded with EPE foam molds, and suspended bends for shock absorption.

- Key Component Protection:

- Silicone rings are fitted around groove areas to prevent impact and deformation;

- Wear-resistant PET protective film is applied to the outer sides of bends.

- Smart Traceability Packaging:

- Outer box printed with installation angle diagram (22.5° mark);

- QR code linked to pressure test report, scan to verify authenticity.

- Large Item Dedicated Solution:

- 10“-12” elbows use steel frame wooden pallets with anti-slip rubber nails on the bottom;

- Single pallet load limit of 1 piece, with “center of gravity offset” warning label.

Available size

Size | Center to end | ||

Inch | DN | mm | L(mm) |

1″ | 25 | 33.7 | 41 |

1-1/4″ | 32 | 42.4 | 45 |

1-1/2″ | 40 | 48.3 | 45 |

2″ | 50 | 60.3 | 48 |

2-1/2″ | 65 | 73.0 | 51 |

2-1/2″ | 65 | 76.1 | 51 |

3″ | 80 | 88.9 | 57 |

4″ | 100 | 114.3 | 73 |

5″ | 125 | 139.7 | 73 |

6″ | 150 | 165.1 | 79 |

6″ | 150 | 168.3 | 79 |

8″ | 200 | 219.1 | 98 |

10″ | 250 | 273.0 | 111 |

12″ | 300 | 323.9 | 124 |

- Fine-tuning pipe routing: Suitable for scenarios requiring precise turning at small angles (e.g., densely packed chemical plants, precision instrumentation piping systems).

- Long-distance gentle curve system: Mining conveying pipelines, municipal water supply main pipelines, achieved through the combination of multiple 22.5° elbows to create smooth curved piping layouts.

- Vibration reduction and noise reduction design: Suitable for pump inlets/outlets and air compressor pipelines, where small-angle turns minimize fluid impact vibrations and noise.

- Space-constrained areas: Ideal for building interlayers and ship engine rooms, where the design minimizes space requirements for turns.

- Fire protection system upgrades: Replaces 90° elbows to retrofit aging pipelines, improving water flow efficiency without requiring significant adjustments to supports.

1. Ultra-low resistance: The 22.5° design reduces pressure loss by 40% compared to 45° elbows, significantly reducing energy consumption.

2. Precision fit: The standard bending radius ensures consistent turning and prevents stress concentration in the pipeline.

3. Superior pressure resistance: The ductile iron (ASTM A536) structure enhances deformation resistance by 25% under 500 psi high pressure.

4. Maintenance-free design:Hot-dip galvanized coating with weather resistance ≥20 years (red paint version suitable for indoor dry environments);Grooved joints self-seal, eliminating the need for regular tightening.

5. Plug-and-play: Compatible with any brand of grooved fittings, installation time is only 1/10 of that required for welded elbows

- Differentiated Protection:

- ≤4 inches: 20 pieces per box, sealed with PE bags + corrugated cardboard partitions, moisture-proof and rust-proof;

- >4 inches: individual wooden boxes with top and bottom lids, embedded with EPE foam molds, and suspended bends for shock absorption.

- Key Component Protection:

- Silicone rings are fitted around groove areas to prevent impact and deformation;

- Wear-resistant PET protective film is applied to the outer sides of bends.

- Smart Traceability Packaging:

- Outer box printed with installation angle diagram (22.5° mark);

- QR code linked to pressure test report, scan to verify authenticity.

- Large Item Dedicated Solution:

- 10“-12” elbows use steel frame wooden pallets with anti-slip rubber nails on the bottom;

- Single pallet load limit of 1 piece, with “center of gravity offset” warning label.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.