HOT PRODUCTS TAGS

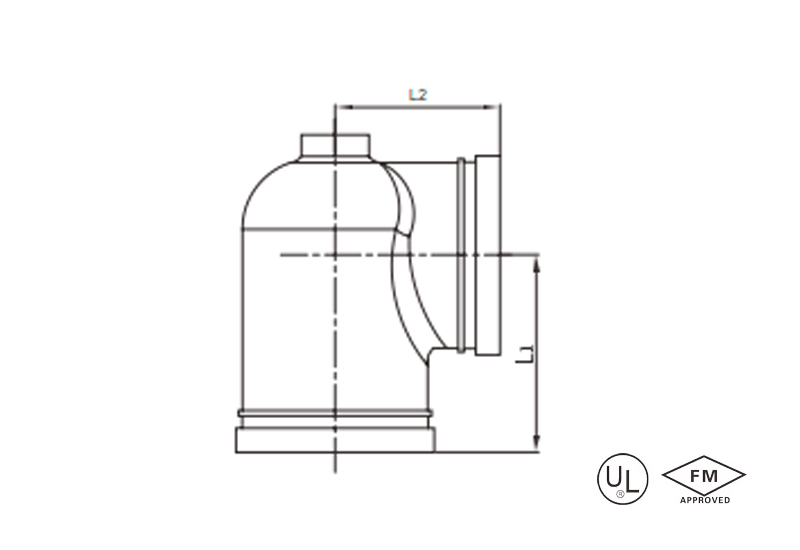

Grooved 90° fire hydrant elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 4″×3″ – 6″×3″

description

Grooved 90° fire hydrant elbow is a 90-degree elbow with a grooved connection structure, which is used to change the direction of the fire protection pipeline

Specification

Available size

Size | Center to end,L(mm) | Threaded outlet | |||

Inch | DN | mm | L1 | L2 |

|

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 106 | 106 | 1″, NPT or BSPT |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 130.5 | 130.5 | 1″, NPT or BSPT |

application

- Underground fire protection pipe network spigots turn vertically toward the ground;

- Building fire protection risers turn horizontally toward sprinkler branch pipes;

- Pump room pipes avoid equipment in compact spaces;

- Connect fire hoses, pressure gauges, and other 1″ threaded interface equipment.

advantages

1. Fire design: 90 degree pivot with one-inch internal threaded outlet (NPT/ BSPT) found at both ends to connect directly to fire fighting equipment without requiring adaptors.

2. Interface with two functions: One for the quick assembly of main branch grooved clamps and another for the flexible expansion of branch outlet threaded outlets, which increases construction efficiency by 60%

3. High-pressure explosion-proof structure: ductile casting iron resisting water hammer impact, 0 leakage under 300–500 psi conditions—making sure emergency safety during a fire.

4. Extreme weather resistance, hot-galvanized or red-painted surface can effectively against corrosion suitable for humidity-ridden and outdoor installation.

5. Global fire protection pipe standard: UL/FM fire safety certification, comply with the world’s major fire protection codes

packing

- Individual protection:

- Threaded outlet wax coating to prevent damage + anti-rust oil coating on inner wall

- Overall bubble wrap wrapping with thickened cushioning at joints

- Unified packaging solution:

- High-strength five-layer corrugated cardboard box + EPE foam custom mold

- One piece per box, with threaded dust cap

- Outer box labeling: Red “Fire Safety Use Only” warning label + “Threaded Joint Impact Protection” icon, specification labeling (e.g., “90° Fire Safety Elbow 4”×3“ NPT”), UL/FM certification label + gross weight/net weight

- Export compliance: Complies with ISTA 3E standards, box secured with steel straps in a cross pattern.

Available size

Size | Center to end,L(mm) | Threaded outlet | |||

Inch | DN | mm | L1 | L2 |

|

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 106 | 106 | 1″, NPT or BSPT |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 130.5 | 130.5 | 1″, NPT or BSPT |

- Underground fire protection pipe network spigots turn vertically toward the ground;

- Building fire protection risers turn horizontally toward sprinkler branch pipes;

- Pump room pipes avoid equipment in compact spaces;

- Connect fire hoses, pressure gauges, and other 1″ threaded interface equipment.

1. Fire design: 90 degree pivot with one-inch internal threaded outlet (NPT/ BSPT) found at both ends to connect directly to fire fighting equipment without requiring adaptors.

2. Interface with two functions: One for the quick assembly of main branch grooved clamps and another for the flexible expansion of branch outlet threaded outlets, which increases construction efficiency by 60%

3. High-pressure explosion-proof structure: ductile casting iron resisting water hammer impact, 0 leakage under 300–500 psi conditions—making sure emergency safety during a fire.

4. Extreme weather resistance, hot-galvanized or red-painted surface can effectively against corrosion suitable for humidity-ridden and outdoor installation.

5. Global fire protection pipe standard: UL/FM fire safety certification, comply with the world’s major fire protection codes

- Individual protection:

- Threaded outlet wax coating to prevent damage + anti-rust oil coating on inner wall

- Overall bubble wrap wrapping with thickened cushioning at joints

- Unified packaging solution:

- High-strength five-layer corrugated cardboard box + EPE foam custom mold

- One piece per box, with threaded dust cap

- Outer box labeling: Red “Fire Safety Use Only” warning label + “Threaded Joint Impact Protection” icon, specification labeling (e.g., “90° Fire Safety Elbow 4”×3“ NPT”), UL/FM certification label + gross weight/net weight

- Export compliance: Complies with ISTA 3E standards, box secured with steel straps in a cross pattern.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.