HOT PRODUCTS TAGS

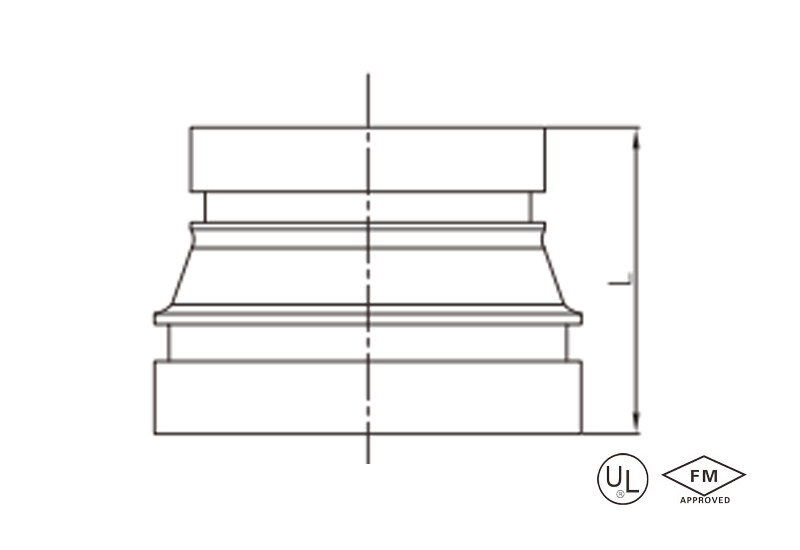

Grooved concentric reducer

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4″×1″ – 12″×10″

description

Grooved concentric reducer is a concentric reducer fitting. The diameters at both ends are different and the centerlines coincide. It is used to join pipes of different diameters by groove connection

Specification

Available size

Size | Center to end | ||

Inch | DN | mm | L(mm) |

1-1/4″ × 1″ | 32 × 25 | 42.4 × 33.7 | 64 |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 64 |

1-1/2″ × 1-1/4″ | 40 × 32 | 48.3 × 42.4 | 64 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 64 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 76 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 141.3 × 73.0 | 89 |

5″ × 3″ | 125 × 80 | 141.3 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 141.3 × 114.3 | 89 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 |

6″ × 5″ | 150 × 125 | 165.1 × 139.7 | 102 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 73.0 | 102 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

6″ × 5″ | 150 × 125 | 168.3 × 139.7 | 102 |

6″ × 5″ | 150 × 125 | 168.3 × 141.3 | 102 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 73.0 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 127 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 127 |

8″ × 5″ | 200 × 125 | 219.1 × 141.3 | 127 |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 127 |

8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 127 |

10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 152 |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 152 |

10″ × 6″ | 250 × 150 | 273.0 × 168.3 | 152 |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 152 |

12″ × 6″ | 300 × 150 | 323.9 × 165.1 | 178 |

12″ × 6″ | 300 × 150 | 323.9 × 168.3 | 178 |

12″ × 8″ | 300 × 200 | 323.9 × 219.1 | 178 |

12″ × 10″ | 300 × 250 | 323.9 × 273.0 | 178 |

application

- Hydraulic balancing system: For variable diameter pipes that do not require complex fluid transition and with centerline perfectly lined up to its whole extent in order to avoid turbulence and cavitation. Designed for the inlets and outlets of pump room, as well as precision fluid treatment systems.

- Space-saving design: It is compact and suitable for equipment-dense areas (such as machine rooms, pipe wells), which replaces the flanged reducer + short connection to reduce leakage points.

- Concentric vertical tubing:with riser uniform stress distribution, pipe system is ideal for high-rise building water supply and drainage and fire opposite pressure tube diameter transitional point of the pipe.

advantages

1. Conical channel design zero resistance: The conical flow channels with concentric right angles reduce the fluid from the large pipe to the small pipe, so that all parts of the conduction become more smooth and smooth, which can reduce 40% loss;

2. Grooved clamp connections, equipping with UL/FM certification, are able to bear 300-500psi pressure and resist water hammer effects, which is suited for seismic resistant and maintenance-free;

3. Installing Minutes: Double-grooved end design eliminates the need for alignment calibration and installation speeds are up to three times faster than flanged connections;

4. Extraordinary Environmental Adaptation: Cast Iron Body (ASTM A536) with red paint/hot dig galv coating, immune to chemical rust in addition to temperatures changes -30 °C to 150 °C.

packing

- Conical Structure Special Protection:

- Both ends are covered with PE anti-scratch film + EVA foam protective rings, and the conical section is wrapped with bubble wrap cushioning layers;

- Anti-Rolling Packaging Solution:

- ≤6″: 10 pieces per box, nested in reinforced cardboard boxes with honeycomb paperboard partitions, with the conical sections arranged alternately to prevent collisions;

- >6″: Each piece is secured using a custom foam mold, with an octagonal pressure-resistant cardboard box added externally;

- Smart Identification System:

- Boxes are printed with flow direction arrows (large end → small end) and pressure rating warning labels;

- A QR code is provided for scanning to access installation guidelines for directional changes, preventing reverse installation.

Available size

Size | Center to end | ||

Inch | DN | mm | L(mm) |

1-1/4″ × 1″ | 32 × 25 | 42.4 × 33.7 | 64 |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 64 |

1-1/2″ × 1-1/4″ | 40 × 32 | 48.3 × 42.4 | 64 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 64 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 64 |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 64 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 64 |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 64 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 64 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 64 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 64 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 64 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 76 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 76 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 |

5″ × 2-1/2″ | 125 × 65 | 141.3 × 73.0 | 89 |

5″ × 3″ | 125 × 80 | 141.3 × 88.9 | 89 |

5″ × 4″ | 125 × 100 | 141.3 × 114.3 | 89 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 |

6″ × 5″ | 150 × 125 | 165.1 × 139.7 | 102 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 102 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 73.0 | 102 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 76.1 | 102 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 |

6″ × 5″ | 150 × 125 | 168.3 × 139.7 | 102 |

6″ × 5″ | 150 × 125 | 168.3 × 141.3 | 102 |

8″ × 2″ | 200 × 50 | 219.1 × 60.3 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 73.0 | 127 |

8″ × 2-1/2″ | 200 × 65 | 219.1 × 76.1 | 127 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 127 |

8″ × 5″ | 200 × 125 | 219.1 × 141.3 | 127 |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 127 |

8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 127 |

10″ × 4″ | 250 × 100 | 273.0 × 114.3 | 152 |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 152 |

10″ × 6″ | 250 × 150 | 273.0 × 168.3 | 152 |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 152 |

12″ × 6″ | 300 × 150 | 323.9 × 165.1 | 178 |

12″ × 6″ | 300 × 150 | 323.9 × 168.3 | 178 |

12″ × 8″ | 300 × 200 | 323.9 × 219.1 | 178 |

12″ × 10″ | 300 × 250 | 323.9 × 273.0 | 178 |

- Hydraulic balancing system: For variable diameter pipes that do not require complex fluid transition and with centerline perfectly lined up to its whole extent in order to avoid turbulence and cavitation. Designed for the inlets and outlets of pump room, as well as precision fluid treatment systems.

- Space-saving design: It is compact and suitable for equipment-dense areas (such as machine rooms, pipe wells), which replaces the flanged reducer + short connection to reduce leakage points.

- Concentric vertical tubing:with riser uniform stress distribution, pipe system is ideal for high-rise building water supply and drainage and fire opposite pressure tube diameter transitional point of the pipe.

1. Conical channel design zero resistance: The conical flow channels with concentric right angles reduce the fluid from the large pipe to the small pipe, so that all parts of the conduction become more smooth and smooth, which can reduce 40% loss;

2. Grooved clamp connections, equipping with UL/FM certification, are able to bear 300-500psi pressure and resist water hammer effects, which is suited for seismic resistant and maintenance-free;

3. Installing Minutes: Double-grooved end design eliminates the need for alignment calibration and installation speeds are up to three times faster than flanged connections;

4. Extraordinary Environmental Adaptation: Cast Iron Body (ASTM A536) with red paint/hot dig galv coating, immune to chemical rust in addition to temperatures changes -30 °C to 150 °C.

- Conical Structure Special Protection:

- Both ends are covered with PE anti-scratch film + EVA foam protective rings, and the conical section is wrapped with bubble wrap cushioning layers;

- Anti-Rolling Packaging Solution:

- ≤6″: 10 pieces per box, nested in reinforced cardboard boxes with honeycomb paperboard partitions, with the conical sections arranged alternately to prevent collisions;

- >6″: Each piece is secured using a custom foam mold, with an octagonal pressure-resistant cardboard box added externally;

- Smart Identification System:

- Boxes are printed with flow direction arrows (large end → small end) and pressure rating warning labels;

- A QR code is provided for scanning to access installation guidelines for directional changes, preventing reverse installation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.