HOT PRODUCTS TAGS

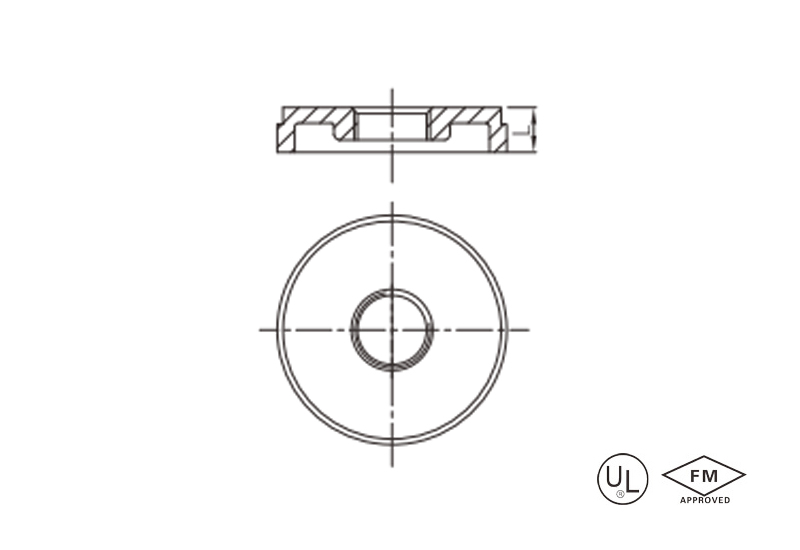

Grooved drain cap with concentric hole

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Centre hole: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″×1″ – 10″×1″

description

Grooved drain cap with concentric hole is a kind of drainage pipe cap with a grooved connection structure. It has concentric holes and is usually used at the end of the pipe. It can be used for drainage or connecting other pipe fittings

Specification

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 24 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 24 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 24 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 24 |

3″ × 1/2″ | 80 × 15 | 88.9 × 21.3 | 24 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 24 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 24 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 24 |

4″ × 1/2″ | 100 × 15 | 114.3 × 21.3 | 27 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 27 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 27 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 27 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 27 |

6″ × 1/2″ | 150 × 15 | 165.1 × 21.3 | 27 |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 27 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 27 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 25 |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 27 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 27 |

8″ × 1″ | 200 × 25 | 219.1 × 33.7 | 30 |

10″ × 1″ | 250 × 25 | 273.0 × 33.7 | 32 |

application

- HVAC condensate drainage, dust prevention for heating system pressure relief ports;

- Industrial pipelines (chemical/oil and gas/water supply and drainage) low point slag and sewage drainage;

- Ship ballast water drainage, food factory CIP cleaning drainage;

- Underground pipeline maintenance well drainage and backflow prevention;

- And connection of pressure gauges, sensors, and other external thread monitoring equipment.

advantages

1. Sealed Drainage Dual Function: Sealed drainage dual function, integrated central hole (NPT / BSPT) on the end cap of the groove, can achieve pipe sealing with Swabbing/ connecting equipment and draining at the same time.

2. Drainage and Corrosion: The design which prevents the residual of liquid at the bottom will not cause bacteria growth, pipe wall corrosion.

3. Fast installation, 30s locking and grooving clamps, quick connection with valves/hoses by using internal hole without extra fixture centering, reducing 50% workload compared to stainless take-off platform.

4. The technology is more suitable for designing the high-strength weather resistance of ductile iron, no rust after acid-alkali and seawater corrosion, meets the 20-year lifespan.

5. Safety certification: Certified by UL/FM, with no leakage at pressures between 300–500 psi.

packing

- Individual protection: Drain holes filled with wax to prevent blockage + rust-proof oil + bubble wrap full coverage to prevent rust during sea transport.

- Small sizes (2“-4”): Corrugated cardboard box with EPE foam layers for secure fixation, with threaded hole dust covers.

- Large sizes (5“-10”): Five-layer reinforced cardboard box + custom foam mold, secured with steel straps.

- Outer box labeling: Red “Drainage holes upward ↑” icon, product name (e.g., “Grooved Drainage End Cap 3”×1“ NPT”), quantity, UL/FM certification, weight.

- Export compliance: Complies with ISTA 3A standards; 10″ specifications can opt for wooden boxes.

Available size

Size | End to end | ||

Inch | DN | mm | L(mm) |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 24 |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 24 |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 24 |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 24 |

3″ × 1/2″ | 80 × 15 | 88.9 × 21.3 | 24 |

3″ × 1″ | 80 × 25 | 88.9 × 33.7 | 24 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 24 |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 24 |

4″ × 1/2″ | 100 × 15 | 114.3 × 21.3 | 27 |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 27 |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 27 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 27 |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 27 |

6″ × 1/2″ | 150 × 15 | 165.1 × 21.3 | 27 |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 27 |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 27 |

6″ × 1″ | 150 × 25 | 168.3 × 33.7 | 25 |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 27 |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 27 |

8″ × 1″ | 200 × 25 | 219.1 × 33.7 | 30 |

10″ × 1″ | 250 × 25 | 273.0 × 33.7 | 32 |

- HVAC condensate drainage, dust prevention for heating system pressure relief ports;

- Industrial pipelines (chemical/oil and gas/water supply and drainage) low point slag and sewage drainage;

- Ship ballast water drainage, food factory CIP cleaning drainage;

- Underground pipeline maintenance well drainage and backflow prevention;

- And connection of pressure gauges, sensors, and other external thread monitoring equipment.

1. Sealed Drainage Dual Function: Sealed drainage dual function, integrated central hole (NPT / BSPT) on the end cap of the groove, can achieve pipe sealing with Swabbing/ connecting equipment and draining at the same time.

2. Drainage and Corrosion: The design which prevents the residual of liquid at the bottom will not cause bacteria growth, pipe wall corrosion.

3. Fast installation, 30s locking and grooving clamps, quick connection with valves/hoses by using internal hole without extra fixture centering, reducing 50% workload compared to stainless take-off platform.

4. The technology is more suitable for designing the high-strength weather resistance of ductile iron, no rust after acid-alkali and seawater corrosion, meets the 20-year lifespan.

5. Safety certification: Certified by UL/FM, with no leakage at pressures between 300–500 psi.

- Individual protection: Drain holes filled with wax to prevent blockage + rust-proof oil + bubble wrap full coverage to prevent rust during sea transport.

- Small sizes (2“-4”): Corrugated cardboard box with EPE foam layers for secure fixation, with threaded hole dust covers.

- Large sizes (5“-10”): Five-layer reinforced cardboard box + custom foam mold, secured with steel straps.

- Outer box labeling: Red “Drainage holes upward ↑” icon, product name (e.g., “Grooved Drainage End Cap 3”×1“ NPT”), quantity, UL/FM certification, weight.

- Export compliance: Complies with ISTA 3A standards; 10″ specifications can opt for wooden boxes.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.