HOT PRODUCTS TAGS

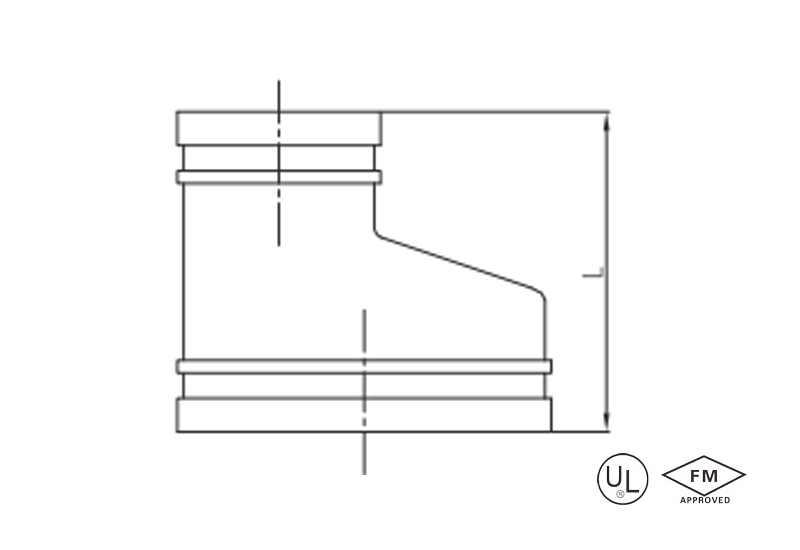

Grooved eccentric reducer

·Standard: ANS / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2-1/2″×2″ – 10″×8″

description

Grooved eccentric reducer is an eccentric reducer with different diameters at both ends and a deviated centerline. It is used in piping systems to connect pipes of different diameters and to prevent fluid accumulation or gas blockage

Specification

Available size

Size | Center to end,L(mm) | |||

Inch | DN | mm | Short | Long |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 | / |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 | 89 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 | / |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 | / |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 | 102 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 | / |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 | 102 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 | 102 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 | / |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 | / |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 | 127 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 | / |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 | 140 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 | 140 |

6″ × 5″ | 150 × 125 | 165.1 × 139.7 | 102 | 140 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 | 140 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 | 140 |

6″ × 5″ | 150 × 125 | 168.3 × 139.7 | 102 | 140 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 | / |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 | 215 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 127 | / |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 127 | 215 |

8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 127 | 215 |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 152 | / |

10″ × 6″ | 250 × 150 | 273.0 × 168.3 | 152 | / |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 152 | 215 |

application

- Preventing liquid accumulation is the design focus:This type is designed for pipeline systems that require to avoid fluid residues or air pocket blockages, due to eccentric type, make the bottom of pipeline always being plane, applicable for pump room suction ends,steam system and chemical medium transportation pipelines.

- Only takes up little space: As the eccentric reducing joint is smaller than the corresponding size of the eccentric (or concentrative) pipe and flange, it can be widely used in low-lying places such as under equipment, interlayer projection racks, etc., replacing the traditional method that combines eccentric (or concentric) pipes with flanges.

- Special Medium Conveyance: conveying fluids containing particles or high viscosity(e.g., wastewater, slurry), reducing sedimentation and blockage in the reducer section

advantages

1. The centerline offset structure of the intelligent anti-blocking design completely eliminates the bottom liquid accumulation zone to prevent cavitation and silt accumulation, thereby reducing maintenance costs by 50%;

2. LifeLong sealing performance and seismic resistance, stable flow performance:TheGrooved Clamp is UL/FM listed with a pressure rating of 300-500 psi to withstand water hammer and high frequency vibration;

3. Installation At the Minute Level: Pre-aligned groove design at both ends makes horizontal alignment unnecessary and increases installation efficiency by 3 fold compared to flanged designs;

4. Adapt to the poor or extreme temperature environments, Ductile Iron Body (ASTM A536) with red paint /Hot-Dip Galvanized coating can resist acid-alkali corrosion and -30 degree Celsius to 200 degree Celsius temperature;

5. Engineered flexibility: Short or Long version (short to save time on install, long for smooth flow transition) – fits your operational needs.

packing

- Eccentric Structure Special Protection:

- Large openings covered with PE anti-scratch film + EVA foam rings; the eccentric side is labeled with an “↑ top indicator” to prevent reverse placement;

- Asymmetric parts of the cone are filled with custom foam modules to prevent deformation from transportation impacts;

- Anti-Rolling Packaging Solution:

- ≤6″: each 10 pcs per box of eccentric side up, one honeycomb cardboard partition box for packing;

- >6″: Secured with an ”L-shaped” wooded bracket attached with a steel-banded box wrapped in moisture-proof aluminum foil; >

- Intelligent Error-Proofing System:

- Boxes are identified in the field with some “Eccentric Side Up Installation” diagrams and pressure rating warning labels;

- Quick locator card with an independent sealed bag (including eccentric direction Grid2.0 and code scan video tutorial).

Available size

Size | Center to end,L(mm) | |||

Inch | DN | mm | Short | Long |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 64 | / |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 64 | 89 |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 73.0 | 64 | / |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 64 | / |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 76 | 102 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 73.0 | 76 | / |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 76 | 102 |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 76 | 102 |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 89 | / |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 89 | / |

5″ × 4″ | 125 × 100 | 139.7 × 114.3 | 89 | 127 |

6″ × 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 102 | / |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 102 | 140 |

6″ × 4″ | 150 × 100 | 165.1 × 114.3 | 102 | 140 |

6″ × 5″ | 150 × 125 | 165.1 × 139.7 | 102 | 140 |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 102 | 140 |

6″ × 4″ | 150 × 100 | 168.3 × 114.3 | 102 | 140 |

6″ × 5″ | 150 × 125 | 168.3 × 139.7 | 102 | 140 |

8″ × 3″ | 200 × 80 | 219.1 × 88.9 | 127 | / |

8″ × 4″ | 200 × 100 | 219.1 × 114.3 | 127 | 215 |

8″ × 5″ | 200 × 125 | 219.1 × 139.7 | 127 | / |

8″ × 6″ | 200 × 150 | 219.1 × 165.1 | 127 | 215 |

8″ × 6″ | 200 × 150 | 219.1 × 168.3 | 127 | 215 |

10″ × 6″ | 250 × 150 | 273.0 × 165.1 | 152 | / |

10″ × 6″ | 250 × 150 | 273.0 × 168.3 | 152 | / |

10″ × 8″ | 250 × 200 | 273.0 × 219.1 | 152 | 215 |

- Preventing liquid accumulation is the design focus:This type is designed for pipeline systems that require to avoid fluid residues or air pocket blockages, due to eccentric type, make the bottom of pipeline always being plane, applicable for pump room suction ends,steam system and chemical medium transportation pipelines.

- Only takes up little space: As the eccentric reducing joint is smaller than the corresponding size of the eccentric (or concentrative) pipe and flange, it can be widely used in low-lying places such as under equipment, interlayer projection racks, etc., replacing the traditional method that combines eccentric (or concentric) pipes with flanges.

- Special Medium Conveyance: conveying fluids containing particles or high viscosity(e.g., wastewater, slurry), reducing sedimentation and blockage in the reducer section

1. The centerline offset structure of the intelligent anti-blocking design completely eliminates the bottom liquid accumulation zone to prevent cavitation and silt accumulation, thereby reducing maintenance costs by 50%;

2. LifeLong sealing performance and seismic resistance, stable flow performance:TheGrooved Clamp is UL/FM listed with a pressure rating of 300-500 psi to withstand water hammer and high frequency vibration;

3. Installation At the Minute Level: Pre-aligned groove design at both ends makes horizontal alignment unnecessary and increases installation efficiency by 3 fold compared to flanged designs;

4. Adapt to the poor or extreme temperature environments, Ductile Iron Body (ASTM A536) with red paint /Hot-Dip Galvanized coating can resist acid-alkali corrosion and -30 degree Celsius to 200 degree Celsius temperature;

5. Engineered flexibility: Short or Long version (short to save time on install, long for smooth flow transition) – fits your operational needs.

- Eccentric Structure Special Protection:

- Large openings covered with PE anti-scratch film + EVA foam rings; the eccentric side is labeled with an “↑ top indicator” to prevent reverse placement;

- Asymmetric parts of the cone are filled with custom foam modules to prevent deformation from transportation impacts;

- Anti-Rolling Packaging Solution:

- ≤6″: each 10 pcs per box of eccentric side up, one honeycomb cardboard partition box for packing;

- >6″: Secured with an ”L-shaped” wooded bracket attached with a steel-banded box wrapped in moisture-proof aluminum foil; >

- Intelligent Error-Proofing System:

- Boxes are identified in the field with some “Eccentric Side Up Installation” diagrams and pressure rating warning labels;

- Quick locator card with an independent sealed bag (including eccentric direction Grid2.0 and code scan video tutorial).

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.