HOT PRODUCTS TAGS

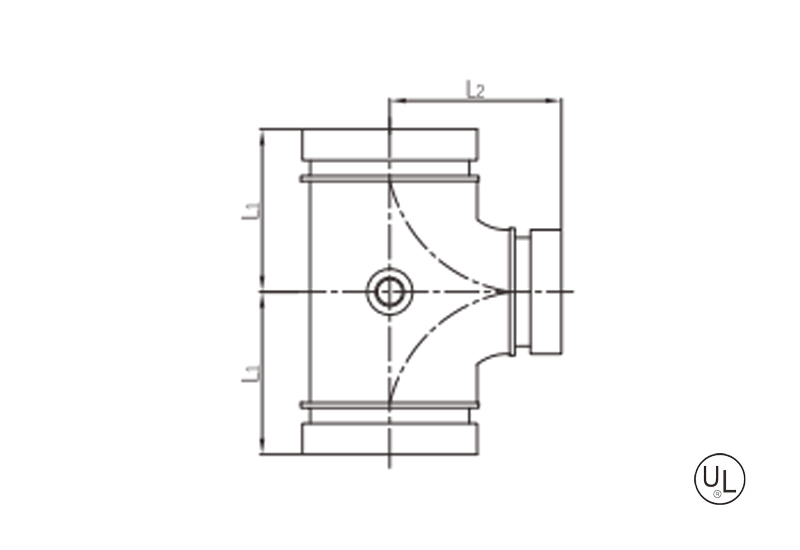

Grooved fire hydrant tee

·Standard: ANSI / UL 213C UL

·Material: Ductile iron ASTM A536, 65-45-12

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 4”×3”×1” – 6”×3”×1”

description

Grooved fire hydrant tee is a special three-way pipe fitting for fire hydrants with a grooved connection structure, which is used to connect fire hydrants with the main pipeline in the fire protection piping system.

Specification

Available size

Size | Center to end,L(mm) | Threaded outlet | |||

Inch | DN | mm | L1 | L2 |

|

4” × 3” × 1” | 100 × 80 × 25 | 114.3 × 88.9 × 33.7 | 102 | 67 | 1″, NPT or BSPT |

6” × 3” × 1” | 150 × 80 × 25 | 165.1 × 88.9 × 33.7 | 130 | 91 | 1″, NPT or BSPT |

application

- Fire protection system core connection components: special quick connectors for fire hydrants and main pipes in fire-fighting pipelines to ensure emergency water supply.

- Emergency engineering adaptation: Large pipe diameter, suitable for branch expansion and renovation (such as municipal fire protection pipe network), industrial plant area, building fire system.

- Flexible deployment: support branch connection in various installation directions to adapt the complex terrain for fire hydrant installation.

advantages

1. DESIGN OF QUICK-RESPONSE: The built-in ribbed design allows second-level installation, greatly improving the construction and maintenance efficiency of the fire protection system.

2. Double Sealing Guarantee: The grooved and threaded NPT/BSPT interface of the main pipe ensures zero leakage at high pressure.

3. Resistance To Extreme Conditions :With Ductile iron material (ASTM A536) have a compressive strength of 300-500 psi which will be with fire water hammer resistance.

4. Durable: Red paint or hot-dip galvanized surface treatment to resist corrosion in outdoor environment, prolonging service life.

5. Compliance Certification: CE & ANSI/UL- Certified 40&90 international safety standards; Meets mandatory requirements of fire protection systems.

packing

- Interface protection: the threaded outlet is attached to a sealing cap and anti-rust coating, and is installed with a PE protective film on grooves.

- Earthquake Resistant Packaging : Every single item is housed in a custom foam tool and packed in thick die-cut cardboard (sheets).

- Fire safety mark, product model canbe appear on the box surface and by searching emergency equipment signaling. The priority is to transport and deliver.

Available size

Size | Center to end,L(mm) | Threaded outlet | |||

Inch | DN | mm | L1 | L2 |

|

4” × 3” × 1” | 100 × 80 × 25 | 114.3 × 88.9 × 33.7 | 102 | 67 | 1″, NPT or BSPT |

6” × 3” × 1” | 150 × 80 × 25 | 165.1 × 88.9 × 33.7 | 130 | 91 | 1″, NPT or BSPT |

- Fire protection system core connection components: special quick connectors for fire hydrants and main pipes in fire-fighting pipelines to ensure emergency water supply.

- Emergency engineering adaptation: Large pipe diameter, suitable for branch expansion and renovation (such as municipal fire protection pipe network), industrial plant area, building fire system.

- Flexible deployment: support branch connection in various installation directions to adapt the complex terrain for fire hydrant installation.

1. DESIGN OF QUICK-RESPONSE: The built-in ribbed design allows second-level installation, greatly improving the construction and maintenance efficiency of the fire protection system.

2. Double Sealing Guarantee: The grooved and threaded NPT/BSPT interface of the main pipe ensures zero leakage at high pressure.

3. Resistance To Extreme Conditions :With Ductile iron material (ASTM A536) have a compressive strength of 300-500 psi which will be with fire water hammer resistance.

4. Durable: Red paint or hot-dip galvanized surface treatment to resist corrosion in outdoor environment, prolonging service life.

5. Compliance Certification: CE & ANSI/UL- Certified 40&90 international safety standards; Meets mandatory requirements of fire protection systems.

- Interface protection: the threaded outlet is attached to a sealing cap and anti-rust coating, and is installed with a PE protective film on grooves.

- Earthquake Resistant Packaging : Every single item is housed in a custom foam tool and packed in thick die-cut cardboard (sheets).

- Fire safety mark, product model canbe appear on the box surface and by searching emergency equipment signaling. The priority is to transport and deliver.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.