HOT PRODUCTS TAGS

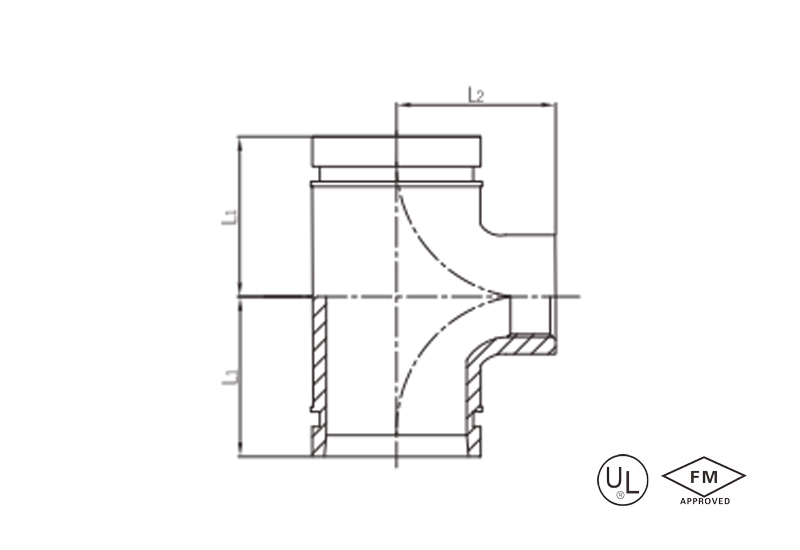

Grooved reducing tee with female threaded branch

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Type: Short / Standard

·Branch: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4”×1” – 6″×3″

description

Grooved reducing tee with female threaded branch is a reducing three-way pipe fitting. Its branch interface is designed with an internal thread and is used for the connection of reducing pipes and the branch installation of components that require internal thread connection

Specification

Available size

Size | Center to end (mm),Short | Center to end (mm),Standard | ||||

Inch | DN | mm | L1 | L2 | L1 | L2 |

1-1/4” × 1” | 32 × 25 | 42.4 × 33.7 | 60 | 60 | / | / |

1-1/2′ ‘× 1” | 40 × 25 | 48.3 × 33.7 | 60 | 60 | / | / |

1-1/2” × 1-1/4” | 40 × 32 | 48.3 × 42.4 | 60 | 60 | / | / |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 70 | 70 | 83 | 83 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 70 | 70 | / | / |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 70 | 70 | / | / |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 76 | 76 | / | / |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 76 | 76 | 95 | 95 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 76 | 76 | 95 | 95 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 76 | 76 | / | / |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 76 | 76 | / | / |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 76 | 76 | / | / |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 76 | 76 | / | / |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 | / | / |

3″ × 1 | 80 × 25 | 88.9 × 33.7 | 86 | 86 | 108 | 108 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 86 | 86 | 108 | 108 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 86 | 86 | / | / |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 | / | / |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 86 | 86 | / | / |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 101 | 101 | 127 | 127 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 101 | 101 | / | / |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 101 | 101 | 127 | 127 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 | 127 | 127 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 101 | 101 | / | / |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 | 127 | 127 |

5″ × 1″ | 125 × 25 | 139.7 × 33.7 | 124 | 124 | / | / |

5″ × 1-1/4″ | 125 × 32 | 139.7 × 42.4 | 124 | 124 | / | / |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 124 | 124 | / | / |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 124 | 124 | / | / |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 124 | 124 | / | / |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 124 | 124 | / | / |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 140 | 140 | / | / |

6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 140 | 140 | / | / |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 140 | 140 | / | / |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 | / | / |

6″× 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 | / | / |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 | / | / |

6″ × 1-1/4″ | 150 × 32 | 168.3 × 42.4 | 140 | 140 | / | / |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 140 | 140 | / | / |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 140 | 140 | 165 | 165 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 76.1 | 140 | 140 | / | / |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 140 | 140 | 165 | 165 |

application

- Flexible device connection: Breathable joint, specially designed for the connection of small manometer and valve or sensor to pipe with different diameter. Internal thread branch pipe directly fits threaded interface devices.

- System Expansion Node: for the branching point of monitoring/control units (e.g., in water treatment and HVAC systems) where devices are frequently added or removed.

- Space renovation of compact products: this structure of short type is used to install in dense equipment area (machine room and pipe well).

advantages

1. Two-way connection: Quick coupling at the pipeline (The main pipe groove) + Precision sealing at another pipeline (size NPT/BSPT), making it easier to integrate equipment.

2. Types: Short (compact) and standard (universal) models to fit different engineering situations;

3. No leaking: One-piece ductile cast iron (ASTM A536) construction and precision threads can handle pressure surges of 300-500 psi

4. Excellent corrosion resistance In water system, use red paint or hot dip galvanized surface treatment prolong service life.

5. International Compliance: Meets ANSI/UL/FM standards certifications and requirements for fire protection, industrial systems.

packing

- Threaded joint preservative:

- Fill with anti-rust grease, and use a plastic sleeve to screw down to prevent impact and deformation.

- Classified packaging:

- Short-type products: 10 pieces in a carton box with upper and lower partition.

- General-purpose: independent packaging, with foam molds to support the main body

- Smart Traceability:

- The carton is pasted with the anti-counterfeiting label and QR code (can be scanned to get thread interface compatibility guidelines), and labeled “Precision Threads Pressure Resistant and Moisture Proof” on the outside of the carton.

Available size

Size | Center to end (mm),Short | Center to end (mm),Standard | ||||

Inch | DN | mm | L1 | L2 | L1 | L2 |

1-1/4” × 1” | 32 × 25 | 42.4 × 33.7 | 60 | 60 | / | / |

1-1/2′ ‘× 1” | 40 × 25 | 48.3 × 33.7 | 60 | 60 | / | / |

1-1/2” × 1-1/4” | 40 × 32 | 48.3 × 42.4 | 60 | 60 | / | / |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 70 | 70 | 83 | 83 |

2″ × 1-1/4″ | 50 × 32 | 60.3 × 42.4 | 70 | 70 | / | / |

2″ × 1-1/2″ | 50 × 40 | 60.3 × 48.3 | 70 | 70 | / | / |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 76 | 76 | / | / |

2-1/2″ × 1-1/4″ | 65 × 32 | 73.0 × 42.4 | 76 | 76 | 95 | 95 |

2-1/2″ × 1-1/2″ | 65 × 40 | 73.0 × 48.3 | 76 | 76 | 95 | 95 |

2-1/2″ × 2″ | 65 × 50 | 73.0 × 60.3 | 76 | 76 | / | / |

2-1/2″ × 1″ | 65 × 25 | 76.1 × 33.7 | 76 | 76 | / | / |

2-1/2″ × 1-1/4″ | 65 × 32 | 76.1 × 42.4 | 76 | 76 | / | / |

2-1/2″ × 1-1/2″ | 65 × 40 | 76.1 × 48.3 | 76 | 76 | / | / |

2-1/2″ × 2″ | 65 × 50 | 76.1 × 60.3 | 76 | 76 | / | / |

3″ × 1 | 80 × 25 | 88.9 × 33.7 | 86 | 86 | 108 | 108 |

3″ × 1-1/4″ | 80 × 32 | 88.9 × 42.4 | 86 | 86 | 108 | 108 |

3″ × 1-1/2″ | 80 × 40 | 88.9 × 48.3 | 86 | 86 | / | / |

3″ × 2″ | 80 × 50 | 88.9 × 60.3 | 86 | 86 | / | / |

3″ × 2-1/2″ | 80 × 65 | 88.9 × 76.1 | 86 | 86 | / | / |

4″ × 1″ | 100 × 25 | 114.3 × 33.7 | 101 | 101 | 127 | 127 |

4″ × 1-1/4″ | 100 × 32 | 114.3 × 42.4 | 101 | 101 | / | / |

4″ × 1-1/2″ | 100 × 40 | 114.3 × 48.3 | 101 | 101 | 127 | 127 |

4″ × 2″ | 100 × 50 | 114.3 × 60.3 | 101 | 101 | 127 | 127 |

4″ × 2-1/2″ | 100 × 65 | 114.3 × 76.1 | 101 | 101 | / | / |

4″ × 3″ | 100 × 80 | 114.3 × 88.9 | 101 | 101 | 127 | 127 |

5″ × 1″ | 125 × 25 | 139.7 × 33.7 | 124 | 124 | / | / |

5″ × 1-1/4″ | 125 × 32 | 139.7 × 42.4 | 124 | 124 | / | / |

5″ × 1-1/2″ | 125 × 40 | 139.7 × 48.3 | 124 | 124 | / | / |

5″ × 2″ | 125 × 50 | 139.7 × 60.3 | 124 | 124 | / | / |

5″ × 2-1/2″ | 125 × 65 | 139.7 × 76.1 | 124 | 124 | / | / |

5″ × 3″ | 125 × 80 | 139.7 × 88.9 | 124 | 124 | / | / |

6″ × 1″ | 150 × 25 | 165.1 × 33.7 | 140 | 140 | / | / |

6″ × 1-1/4″ | 150 × 32 | 165.1 × 42.4 | 140 | 140 | / | / |

6″ × 1-1/2″ | 150 × 40 | 165.1 × 48.3 | 140 | 140 | / | / |

6″ × 2″ | 150 × 50 | 165.1 × 60.3 | 140 | 140 | / | / |

6″× 2-1/2″ | 150 × 65 | 165.1 × 76.1 | 140 | 140 | / | / |

6″ × 3″ | 150 × 80 | 165.1 × 88.9 | 140 | 140 | / | / |

6″ × 1-1/4″ | 150 × 32 | 168.3 × 42.4 | 140 | 140 | / | / |

6″ × 1-1/2″ | 150 × 40 | 168.3 × 48.3 | 140 | 140 | / | / |

6″ × 2″ | 150 × 50 | 168.3 × 60.3 | 140 | 140 | 165 | 165 |

6″ × 2-1/2″ | 150 × 65 | 168.3 × 76.1 | 140 | 140 | / | / |

6″ × 3″ | 150 × 80 | 168.3 × 88.9 | 140 | 140 | 165 | 165 |

- Flexible device connection: Breathable joint, specially designed for the connection of small manometer and valve or sensor to pipe with different diameter. Internal thread branch pipe directly fits threaded interface devices.

- System Expansion Node: for the branching point of monitoring/control units (e.g., in water treatment and HVAC systems) where devices are frequently added or removed.

- Space renovation of compact products: this structure of short type is used to install in dense equipment area (machine room and pipe well).

1. Two-way connection: Quick coupling at the pipeline (The main pipe groove) + Precision sealing at another pipeline (size NPT/BSPT), making it easier to integrate equipment.

2. Types: Short (compact) and standard (universal) models to fit different engineering situations;

3. No leaking: One-piece ductile cast iron (ASTM A536) construction and precision threads can handle pressure surges of 300-500 psi

4. Excellent corrosion resistance In water system, use red paint or hot dip galvanized surface treatment prolong service life.

5. International Compliance: Meets ANSI/UL/FM standards certifications and requirements for fire protection, industrial systems.

- Threaded joint preservative:

- Fill with anti-rust grease, and use a plastic sleeve to screw down to prevent impact and deformation.

- Classified packaging:

- Short-type products: 10 pieces in a carton box with upper and lower partition.

- General-purpose: independent packaging, with foam molds to support the main body

- Smart Traceability:

- The carton is pasted with the anti-counterfeiting label and QR code (can be scanned to get thread interface compatibility guidelines), and labeled “Precision Threads Pressure Resistant and Moisture Proof” on the outside of the carton.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.