HOT PRODUCTS TAGS

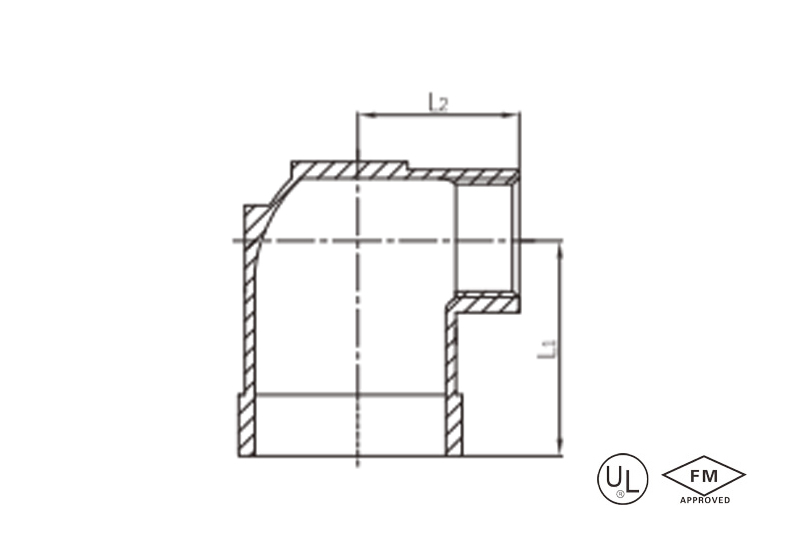

Grooved × female threaded adapter elbow

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Thread run: Female thread, NPT / BSPT

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1-1/4″×1/2″ – 2-1/2″×1″

description

Grooved × female threaded adapter elbow is a kind of elbow pipe fitting with a grooved connection at one end and an internal thread at the other end, which is used to connect grooved pipes with pipes or fittings with external threads

Specification

Available size

Size | Center to end(mm) | |||

Inch | DN | mm | L1 | L2 |

1-1/4″ × 1/2″ | 32 × 15 | 424 × 21.3 | 45 | 31 |

1-1/4″ × 3/4″ | 32 × 20 | 42.4 × 26.9 | 45 | 31 |

1-1/4″ × 1″ | 32 × 25 | 42.4 × 33.7 | 49 | 32 |

1-1/2″ × 1/2″ | 40 × 15 | 48.3 × 21.3 | 45 | 34 |

1-1/2″ × 3/4″ | 40 × 20 | 48.3 × 26.9 | 45 | 34 |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 49 | 36 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 45 | 40 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 45 | 40 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 49 | 42 |

2-1/2″ × 1/2″ | 65 × 15 | 73.0 × 21.3 | 45 | 45 |

2-1/2″ × 3/4″ | 65 × 20 | 73.0 × 26.9 | 45 | 45 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 49 | 46 |

application

- Fire sprinkler branch pipe turning connection external thread valve/nozzle;

- HVAC pipe corner connection thermometer/pressure gauge;

- Industrial equipment (pump body/storage tank) limited space turning connection external thread interface;

- Ship piping compact layout connection instrument sensor.

advantages

1. 90°bend dual interface: Groove end clamp to fix the pipeline for the main pipe + internal thread end (NPT/BSPT) directly connected with an external threaded device, satisfy bending and connecting requirements in one step.

2. Narrow space adaptation: L1/L2 short arm design (see document parameters) minimizes installation space, resolving equipment corner challenges in confined areas.

3. Twice as strong: There is no welding to weaken the connection, and the 3.3-minute installation is approximately three times faster than using a traditional flanged elbow.

4. Leak-proof under high pressure : Ductile iron one piece casting. zero leakage testing certified by UL/FM over 300-500 psi working pressure.

5. Universal standard threads: NPT/BSPT standards, can be matched with American, European and Asian equipment

packing

- Individual protection: Threaded hole wax injection for damage prevention + anti-rust oil coating on inner walls, fully wrapped in bubble wrap, reinforced cushioning layer at elbow joints

- Unified packaging solution: High-strength corrugated cardboard box (25×15×10cm) + EPE foam compartments, each box contains 6 pieces (small size) or 3 pieces (large size), with threaded dust caps

- Outer box labeling: Elbow directional diagram + “Internal threaded end ↑” orientation mark, specification labeling (e.g., “1-1/2” × 1“ NPT L1=49mm”), UL/FM certification mark + quantity/gross weight

- Export compliance: Complies with ISTA 1A standard, stacking height limit of 5 layers.

Available size

Size | Center to end(mm) | |||

Inch | DN | mm | L1 | L2 |

1-1/4″ × 1/2″ | 32 × 15 | 424 × 21.3 | 45 | 31 |

1-1/4″ × 3/4″ | 32 × 20 | 42.4 × 26.9 | 45 | 31 |

1-1/4″ × 1″ | 32 × 25 | 42.4 × 33.7 | 49 | 32 |

1-1/2″ × 1/2″ | 40 × 15 | 48.3 × 21.3 | 45 | 34 |

1-1/2″ × 3/4″ | 40 × 20 | 48.3 × 26.9 | 45 | 34 |

1-1/2″ × 1″ | 40 × 25 | 48.3 × 33.7 | 49 | 36 |

2″ × 1/2″ | 50 × 15 | 60.3 × 21.3 | 45 | 40 |

2″ × 3/4″ | 50 × 20 | 60.3 × 26.9 | 45 | 40 |

2″ × 1″ | 50 × 25 | 60.3 × 33.7 | 49 | 42 |

2-1/2″ × 1/2″ | 65 × 15 | 73.0 × 21.3 | 45 | 45 |

2-1/2″ × 3/4″ | 65 × 20 | 73.0 × 26.9 | 45 | 45 |

2-1/2″ × 1″ | 65 × 25 | 73.0 × 33.7 | 49 | 46 |

- Fire sprinkler branch pipe turning connection external thread valve/nozzle;

- HVAC pipe corner connection thermometer/pressure gauge;

- Industrial equipment (pump body/storage tank) limited space turning connection external thread interface;

- Ship piping compact layout connection instrument sensor.

1. 90°bend dual interface: Groove end clamp to fix the pipeline for the main pipe + internal thread end (NPT/BSPT) directly connected with an external threaded device, satisfy bending and connecting requirements in one step.

2. Narrow space adaptation: L1/L2 short arm design (see document parameters) minimizes installation space, resolving equipment corner challenges in confined areas.

3. Twice as strong: There is no welding to weaken the connection, and the 3.3-minute installation is approximately three times faster than using a traditional flanged elbow.

4. Leak-proof under high pressure : Ductile iron one piece casting. zero leakage testing certified by UL/FM over 300-500 psi working pressure.

5. Universal standard threads: NPT/BSPT standards, can be matched with American, European and Asian equipment

- Individual protection: Threaded hole wax injection for damage prevention + anti-rust oil coating on inner walls, fully wrapped in bubble wrap, reinforced cushioning layer at elbow joints

- Unified packaging solution: High-strength corrugated cardboard box (25×15×10cm) + EPE foam compartments, each box contains 6 pieces (small size) or 3 pieces (large size), with threaded dust caps

- Outer box labeling: Elbow directional diagram + “Internal threaded end ↑” orientation mark, specification labeling (e.g., “1-1/2” × 1“ NPT L1=49mm”), UL/FM certification mark + quantity/gross weight

- Export compliance: Complies with ISTA 1A standard, stacking height limit of 5 layers.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.