HOT PRODUCTS TAGS

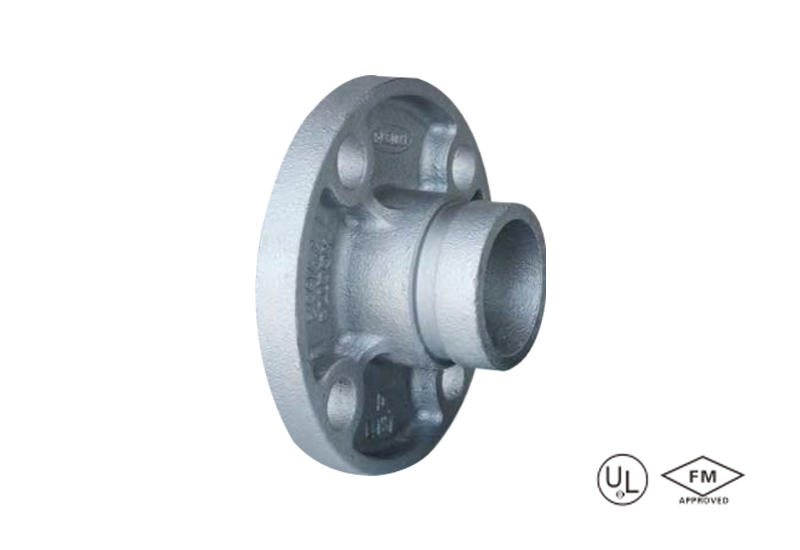

ANSI grooved flange one-piece (Flanged adapter)

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Flanged end: ANSI B16.1 Class 125, B16.42 Class 150, FF or RF

·Rated pressure: 300 psi

·Surface:Red painting / hot dip galvanized

·Range:2″- 24″

description

ANSI grooved flange one-piece (Flanged adapter) is an integrated grooved connection flange that complies with the ANSI standard. It is used as an adapter to achieve grooved connection between the pipe and the flange

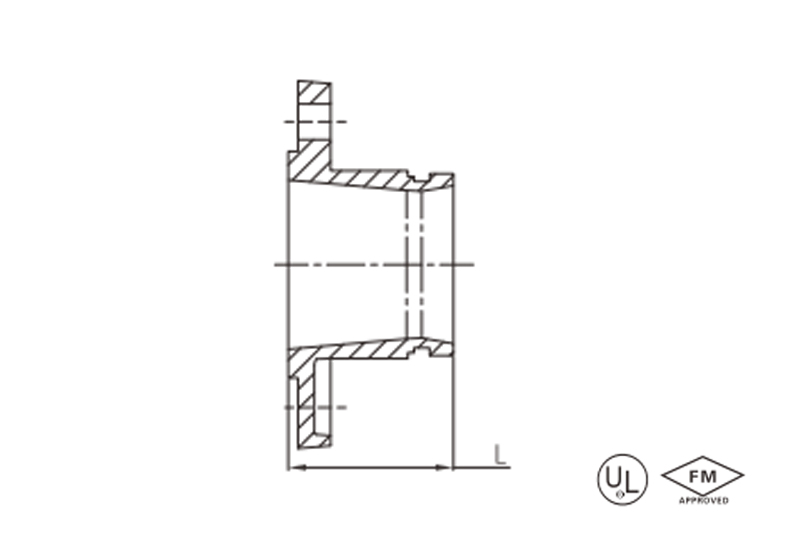

Specification

Available size

Size | L | Bolting for mating flange | Flanged end | |||

Inch | DN | mm | mm | PCD (mm) | Bolt |

|

2″ | 50 | 60.3 | 65 | 120.7 | 4 × 5/8″ | Class 125 / 150 |

2-1/2″ | 65 | 73.0 | 65 | 139.7 | 4 × 5/8″ | Class 125 / 150 |

3″ | 80 | 88.9 | 65 | 152.4 | 4 × 5/8″ | Class 125 / 150 |

4″ | 100 | 114.3 | 70 | 190.5 | 8 × 5/8″ | Class 125 / 150 |

6″ | 150 | 168.3 | 70 | 241.3 | 8 × 3/4″ | Class 125 / 150 |

8″ | 200 | 219.1 | 80 | 298.5 | 8 × 3/4″ | Class 125 / 150 |

10″ | 250 | 273.0 | 85 | 362.0 | 12 × 7/8″ | Class 125 / 150 |

12″ | 300 | 323.8 | 90 | 431.8 | 12 × 7/8″ | Class 125 / 150 |

14″ | 350 | 355.6 | 127 | 476.3 | 12 × 1″ | Class 125 / 150 |

16″ | 400 | 406.4 | 127 | 539.8 | 16 × 1″ | Class 125 / 150 |

24″ | 600 | 610.0 | 152 | 749.3 | 20 × 1-1/4″ | Class 125 / 150 |

application

- Fire Protection Systems: Automatic sprinkler piping, fire pump room connections (UL 213C / FM certified),High-rise building fire protection main/branch pipe transitions.

- Industrial fluid conveyance:Chemical medium pipes, power plant cooling water systems,

- Oil and gas conveyance pipeline flange transition sections.

- Building facilities:HVAC hot and cold water pipes,Water supply and drainage system pump and valve connections, water tank inlets and outlets.

- Special scenarios:Pipes requiring frequent maintenance (e.g., GMP pipes in the food and pharmaceutical industries),Corrosion-resistant connections for ship and port pipeline systems.

advantages

- Seamless design: The combination of groove and flange eliminates the leakage factor, making a tighter connection competitive with ANSI solutions.

- Universal Installation: complies with ANSI Class 125/150 flanges end and FF/RF faces, fit traditional flange system for easy interchange.

- Rapid installation: Groove connections means you can throw the welding and threading equipment away, taking hours off your build.

- Long-life-span: ductile iron material (as per ASTM A536), e-fusion bonded epoxy painting, strong corrosion resistance.

- Wide coverage: Suitable for pipe sizes: 2-inch to 24-inch (DN50-DN600) to meet various requirements.

packing

- Individual items are wrapped in rust-proof paper and bubble wrap to prevent scratches during transportation.

- Products of the same specification are packed in reinforced wooden boxes or pallets and filled with cushioning materials.

- The outer box is clearly marked with the product model, size, quantity, and pressure rating.

- Products with special surface treatments (such as hot-dip galvanizing) are additionally treated with a moisture-proof agent.

Available size

Size | L | Bolting for mating flange | Flanged end | |||

Inch | DN | mm | mm | PCD (mm) | Bolt |

|

2″ | 50 | 60.3 | 65 | 120.7 | 4 × 5/8″ | Class 125 / 150 |

2-1/2″ | 65 | 73.0 | 65 | 139.7 | 4 × 5/8″ | Class 125 / 150 |

3″ | 80 | 88.9 | 65 | 152.4 | 4 × 5/8″ | Class 125 / 150 |

4″ | 100 | 114.3 | 70 | 190.5 | 8 × 5/8″ | Class 125 / 150 |

6″ | 150 | 168.3 | 70 | 241.3 | 8 × 3/4″ | Class 125 / 150 |

8″ | 200 | 219.1 | 80 | 298.5 | 8 × 3/4″ | Class 125 / 150 |

10″ | 250 | 273.0 | 85 | 362.0 | 12 × 7/8″ | Class 125 / 150 |

12″ | 300 | 323.8 | 90 | 431.8 | 12 × 7/8″ | Class 125 / 150 |

14″ | 350 | 355.6 | 127 | 476.3 | 12 × 1″ | Class 125 / 150 |

16″ | 400 | 406.4 | 127 | 539.8 | 16 × 1″ | Class 125 / 150 |

24″ | 600 | 610.0 | 152 | 749.3 | 20 × 1-1/4″ | Class 125 / 150 |

- Fire Protection Systems: Automatic sprinkler piping, fire pump room connections (UL 213C / FM certified),High-rise building fire protection main/branch pipe transitions.

- Industrial fluid conveyance:Chemical medium pipes, power plant cooling water systems,

- Oil and gas conveyance pipeline flange transition sections.

- Building facilities:HVAC hot and cold water pipes,Water supply and drainage system pump and valve connections, water tank inlets and outlets.

- Special scenarios:Pipes requiring frequent maintenance (e.g., GMP pipes in the food and pharmaceutical industries),Corrosion-resistant connections for ship and port pipeline systems.

- Seamless design: The combination of groove and flange eliminates the leakage factor, making a tighter connection competitive with ANSI solutions.

- Universal Installation: complies with ANSI Class 125/150 flanges end and FF/RF faces, fit traditional flange system for easy interchange.

- Rapid installation: Groove connections means you can throw the welding and threading equipment away, taking hours off your build.

- Long-life-span: ductile iron material (as per ASTM A536), e-fusion bonded epoxy painting, strong corrosion resistance.

- Wide coverage: Suitable for pipe sizes: 2-inch to 24-inch (DN50-DN600) to meet various requirements.

- Individual items are wrapped in rust-proof paper and bubble wrap to prevent scratches during transportation.

- Products of the same specification are packed in reinforced wooden boxes or pallets and filled with cushioning materials.

- The outer box is clearly marked with the product model, size, quantity, and pressure rating.

- Products with special surface treatments (such as hot-dip galvanizing) are additionally treated with a moisture-proof agent.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.