HOT PRODUCTS TAGS

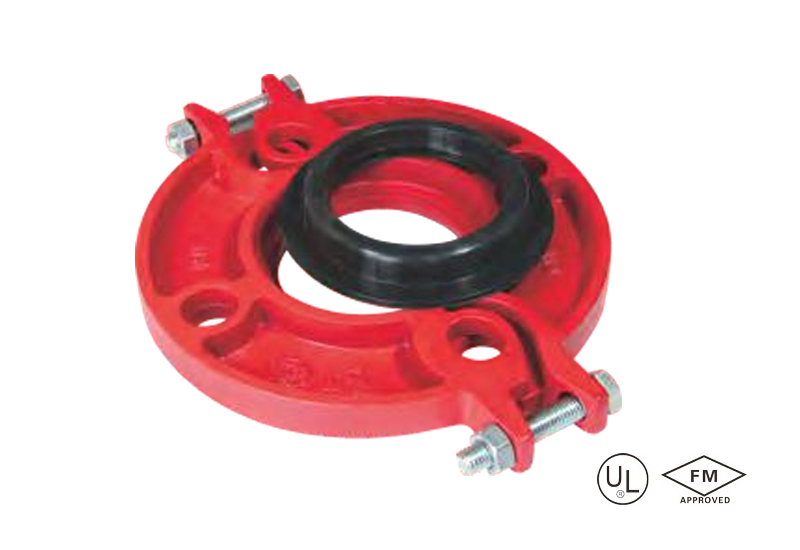

ANSI grooved flange two-piece (Flanged adapter)

·Standard: ANSI / UL 213 UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Bolt & nut: Carbon steel

·Gasket: EPDM, nitrile, silicone rubber, etc.

·Mating flange: ANSI B16.1 Class 125,

B16.42 Class 150, FF, RF, MF, etc.

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 2″ – 14″ (ANSI 125/150)

2-1/2″- 8″ (ANSI 300)

description

ANSI grooved flange two-piece (Flanged adapter) is a two-piece grooved connection flange that complies with the ANSI standard and is used as an adapter to achieve grooved connection between the pipe and the flange

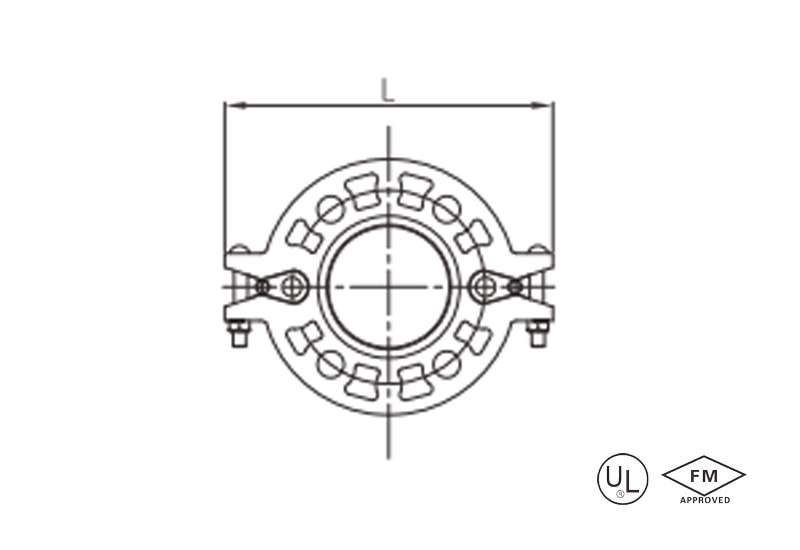

Specification

Available size

| Size | L | Assembly bolting (n – shank bolt) | Bolting for mating flange | Flanged end connection | |||

| Inch | DN | mm | mm | PCD (mm) | Bolt | ||

| 2″ | 50 | 60.3 | 206 | 2 – 3/8″ × 50 | 120.7 | 4 × 5/8″ | Class 125 / 150 |

| 2-1/2″ | 65 | 73.0 | 230 | 2 – 3/8″ × 50 | 139.7 | 4 × 5/8″ | Class 125 / 150 |

| 3″ | 80 | 88.9 | 246 | 2 – 3/8″ × 50 | 152.4 | 4 × 5/8″ | Class 125 / 150 |

| 4″ | 100 | 114.3 | 280 | 2 – 3/8″ × 55 | 190.5 | 8 × 5/8″ | Class 125 / 150 |

| 5″ | 125 | 141.3 | 320 | 2 – 3/8″ × 65 | 215.9 | 8 × 3/4″ | Class 125 / 150 |

| 6″ | 150 | 168.3 | 346 | 2 – 3/8″ × 65 | 241.3 | 8 × 3/4″ | Class 125 / 150 |

| 8″ | 200 | 219.1 | 414.3 | 2- 3/8″ × 70 | 298.5 | 8 × 3/4″ | Class 125 / 150 |

| 10″ | 250 | 273.0 | 481.2 | 2- 3/8″ × 70 | 362.0 | 12 × 7/8″ | Class 125 / 150 |

| 12″ | 300 | 323.8 | 553.3 | 2- 3/8″ × 70 | 431.8 | 12 × 7/8″ | Class 125 / 150 |

| 14″ | 350 | 355.6 | 590.0 | / | 476.3 | 12 × 1″ | Class 125 / 150 |

| 2-1/2″ | 65 | 73.0 | 244 | 2 – 1/2″ × 65 | 139.7 | 8 × 3/4″ | Class 300 |

| 3″ | 80 | 88.9 | 274 | 2 – 1/2″ × 65 | 152.4 | 8 × 3/4″ | Class 300 |

| 4″ | 100 | 114.3 | 310 | 2 – 1/2″ × 65 | 190.5 | 8 × 3/4″ | Class 300 |

| 6″ | 150 | 168.3 | 388 | 2 – 1/2″ × 65 | 241.3 | 12 × 3/4″ | Class 300 |

| 8″ | 200 | 219.1 | 470.4 | 2 – 1/2″ × 75 | 298.5 | 12 × 7/8″ | Class 300 |

application

- Industrial High-Pressure Systems:Process pipelines above 300 psi in petroleum refineries (ANSI 300 grade),Compressed air/steam pipeline flange conversion.

- Fire Protection and Safety Systems:Large complex fire ring pipe connections (UL/FM certified),Quick maintenance interfaces for pump room valve assemblies.

- Building Upgrades and Renovations:Expansion and renovation of existing flanged pipeline systems (no cutting or welding required),Maintenance of pipelines in narrow pipe shafts or ceilings (modular disassembly saves space).

- Special Conditions:Compressor inlets and outlets with frequent vibrations,Pipelines subject to alternating hot and cold temperatures.

advantages

- Modular innovative design: Two-piece structure supports local disassembly and maintenance, avoiding the need to replace the entire pipe section,Independent bolt fastening (carbon steel material) for convenient on-site adjustment.

- Superior sealing combination: Provides EPDM/NBR/silicone multi-material gaskets suitable for oil, high temperature, and chemical media.

- Wide pressure range coverage:Supports ANSI 125/150 (300 psi) to ANSI 300 (500 psi), covering all pressure requirements.

- Wide flange compatibility:Compatible with various flange faces such as FF/RF/MF (ANSI B16.1/B16.42 standards).

- Full-scenario corrosion protection:Dual process of red paint/hot-dip galvanizing, suitable for indoor and outdoor corrosive environments.

packing

- Component Packaging Protection:Flange plates and bolt assemblies are individually sealed in plastic, with gaskets packaged separately in anti-aging bags.

- Seismic Packaging Solution:

- ≤8″ products: Vacuum-formed inner tray + corrugated box (10 sets per box)

- ≥10″ products: Custom wooden box with bolt-fixed mounting holes (to prevent shifting during transport)

- Labeling Enhancement:

- Outer boxes marked with pressure ratings (ANSI 125/150/300) and gasket material codes

- Humidity indicator cards placed inside boxes for hot-dip galvanized products

Available size

| Size | L | Assembly bolting (n – shank bolt) | Bolting for mating flange | Flanged end connection | |||

| Inch | DN | mm | mm | PCD (mm) | Bolt | ||

| 2″ | 50 | 60.3 | 206 | 2 – 3/8″ × 50 | 120.7 | 4 × 5/8″ | Class 125 / 150 |

| 2-1/2″ | 65 | 73.0 | 230 | 2 – 3/8″ × 50 | 139.7 | 4 × 5/8″ | Class 125 / 150 |

| 3″ | 80 | 88.9 | 246 | 2 – 3/8″ × 50 | 152.4 | 4 × 5/8″ | Class 125 / 150 |

| 4″ | 100 | 114.3 | 280 | 2 – 3/8″ × 55 | 190.5 | 8 × 5/8″ | Class 125 / 150 |

| 5″ | 125 | 141.3 | 320 | 2 – 3/8″ × 65 | 215.9 | 8 × 3/4″ | Class 125 / 150 |

| 6″ | 150 | 168.3 | 346 | 2 – 3/8″ × 65 | 241.3 | 8 × 3/4″ | Class 125 / 150 |

| 8″ | 200 | 219.1 | 414.3 | 2- 3/8″ × 70 | 298.5 | 8 × 3/4″ | Class 125 / 150 |

| 10″ | 250 | 273.0 | 481.2 | 2- 3/8″ × 70 | 362.0 | 12 × 7/8″ | Class 125 / 150 |

| 12″ | 300 | 323.8 | 553.3 | 2- 3/8″ × 70 | 431.8 | 12 × 7/8″ | Class 125 / 150 |

| 14″ | 350 | 355.6 | 590.0 | / | 476.3 | 12 × 1″ | Class 125 / 150 |

| 2-1/2″ | 65 | 73.0 | 244 | 2 – 1/2″ × 65 | 139.7 | 8 × 3/4″ | Class 300 |

| 3″ | 80 | 88.9 | 274 | 2 – 1/2″ × 65 | 152.4 | 8 × 3/4″ | Class 300 |

| 4″ | 100 | 114.3 | 310 | 2 – 1/2″ × 65 | 190.5 | 8 × 3/4″ | Class 300 |

| 6″ | 150 | 168.3 | 388 | 2 – 1/2″ × 65 | 241.3 | 12 × 3/4″ | Class 300 |

| 8″ | 200 | 219.1 | 470.4 | 2 – 1/2″ × 75 | 298.5 | 12 × 7/8″ | Class 300 |

- Industrial High-Pressure Systems:Process pipelines above 300 psi in petroleum refineries (ANSI 300 grade),Compressed air/steam pipeline flange conversion.

- Fire Protection and Safety Systems:Large complex fire ring pipe connections (UL/FM certified),Quick maintenance interfaces for pump room valve assemblies.

- Building Upgrades and Renovations:Expansion and renovation of existing flanged pipeline systems (no cutting or welding required),Maintenance of pipelines in narrow pipe shafts or ceilings (modular disassembly saves space).

- Special Conditions:Compressor inlets and outlets with frequent vibrations,Pipelines subject to alternating hot and cold temperatures.

- Modular innovative design: Two-piece structure supports local disassembly and maintenance, avoiding the need to replace the entire pipe section,Independent bolt fastening (carbon steel material) for convenient on-site adjustment.

- Superior sealing combination: Provides EPDM/NBR/silicone multi-material gaskets suitable for oil, high temperature, and chemical media.

- Wide pressure range coverage:Supports ANSI 125/150 (300 psi) to ANSI 300 (500 psi), covering all pressure requirements.

- Wide flange compatibility:Compatible with various flange faces such as FF/RF/MF (ANSI B16.1/B16.42 standards).

- Full-scenario corrosion protection:Dual process of red paint/hot-dip galvanizing, suitable for indoor and outdoor corrosive environments.

- Component Packaging Protection:Flange plates and bolt assemblies are individually sealed in plastic, with gaskets packaged separately in anti-aging bags.

- Seismic Packaging Solution:

- ≤8″ products: Vacuum-formed inner tray + corrugated box (10 sets per box)

- ≥10″ products: Custom wooden box with bolt-fixed mounting holes (to prevent shifting during transport)

- Labeling Enhancement:

- Outer boxes marked with pressure ratings (ANSI 125/150/300) and gasket material codes

- Humidity indicator cards placed inside boxes for hot-dip galvanized products

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.