HOT PRODUCTS TAGS

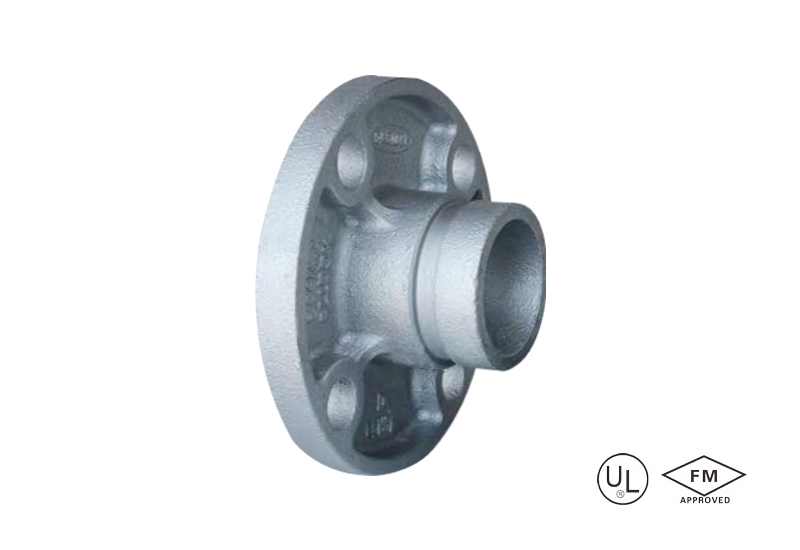

EN grooved flange one-piece (Flanged adapter)

·Standard: ANSI / UL 213C UL / FM

·Material: Ductile iron ASTM A536, 65-45-12

·Flanged end: EN 1092-2, PN10 / PN 16 / PN 25, RF

·Rated pressure: 300 – 500 psi

·Surface: Red painting / hot dip galvanized

·Size range: 1″ – 12″ (PN16)

8″ – 12″ (PN10)

2-1/2″ – 16″ (PN25)

description

EN grooved flange one-piece (Flanged adapter) is an integrated grooved connection flange in compliance with EN standards, used as an adapter to achieve grooved connection between pipes and flanges.

Specification

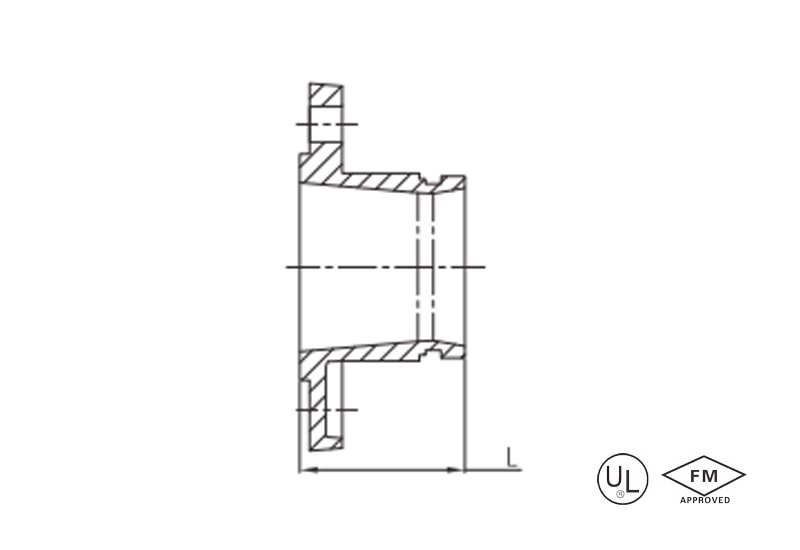

Available size

Size | L | Bolting for mating flange | Flanged end | |||

Inch | DN | mm | mm | PCD (mm) | Bolt |

|

1″ | 25 | 33.7 | 61 | 85 | 4 × M12 | PN 16 |

1-1/4″ | 32 | 42.4 | 61 | 100 | 4 × M16 | PN 16 |

1-1/2″ | 40 | 48.3 | 61 | 110 | 4 × M16 | PN 16 |

2″ | 50 | 60.3 | 61 | 125 | 4 × M16 | PN 16 |

2-1/2″ | 65 | 73.0 | 61 | 145 | 4 × M16 | PN 16 |

2-1/2″ | 65 | 76.1 | 61 | 145 | 4 × M16 | PN 16 |

3″ | 80 | 88.9 | 65 | 160 | 8 × M16 | PN 16 |

4″ | 100 | 114.3 | 70 | 180 | 8 × M16 | PN 16 |

5″ | 125 | 139.7 | 70 | 210 | 8 × M16 | PN 16 |

6″ | 150 | 165.1 | 70 | 240 | 8 × M20 | PN 16 |

6″ | 150 | 168.3 | 70 | 240 | 8 × M20 | PN 16 |

8″ | 200 | 219.1 | 80 | 295 | 12 × M20 | PN 16 |

10″ | 250 | 273.0 | 85 | 355 | 12 × M24 | PN 16 |

12″ | 300 | 323.9 | 90 | 410 | 12 × M24 | PN 16 |

8″ | 200 | 219.1 | 80 | 295 | 8 × M20 | PN 10 |

10″ | 250 | 273.0 | 85 | 350 | 12 × M20 | PN 10 |

12″ | 300 | 323.9 | 90 | 400 | 12 × M20 | PN 10 |

2-1/2″ | 65 | 76.1 | 65 | 145 | 8 × M16 | PN 25 |

3″ | 80 | 88.9 | 65 | 160 | 8 × M16 | PN 25 |

4″ | 100 | 114.3 | 70 | 190 | 8 × M20 | PN 25 |

6″ | 150 | 165.1 | 70 | 250 | 8 × M24 | PN 25 |

8″ | 200 | 219.1 | 80 | 310 | 12 × M24 | PN 25 |

10″ | 250 | 273.0 | 85 | 370 | 12 × M27 | PN 25 |

12″ | 300 | 323.9 | 88 | 430 | 16 × M27 | PN 25 |

14″ | 350 | 355.6 | 100 | 490 | 16 × M30 | PN 25 |

16″ | 400 | 406.4 | 110 | 550 | 16 × M33 | PN 25 |

application

- Industrial Energy Systems:Power plant steam pipes, nuclear power plant cooling water systems,

- Flange transitions for oil and gas transmission pipelines on offshore platforms.

- Municipal and Building Facilities:Fire sprinkler systems compliant with European standards (UL/FM certified),District heating pipes, hospital/laboratory water supply and drainage systems.

- Process Industries:

- Chemical acid and alkali medium transportation,Sanitary-grade pipeline connections for the food and beverage industry.

- Special Environments:Ship ballast water pipelines (PN16 pressure rating),Flange conversion interfaces for pumps and valves in wastewater treatment plants.

advantages

- European Standard Compatible: EN 1092-2 flange ends, PN10/PN16/PN25 pressure ratings to meet European projects.

- High Pressure Use: 500psi (PN25) maximum pressure rating, perfect for all high-pressure industrial plumbing.

- Sizes Available by Pressure Rating (e.g., PN16 –1-12, PN25–2.5- 16), Precisely Matching Engineering Specifications

- Fast Installation: By using the groove connection, so welding be avoided and easy installation finish; with ductile iron material make sure long operation life.

- Corrosion Resistance and Durability – Red paint/hot-dip galvanized dual surface treatment options to suit different corrosive environment needs (e.g. Maritime climates, chemical workshops etc.) .

packing

- Single-item protection: Double-layered packaging with bubble wrap and anti-rust paper, with protective film applied to the flange surface.

- Complete packaging solution:

- PN10/PN16 small-sized products are packaged in corrugated cardboard boxes (20 pieces per box)

- PN25 large-sized products use custom wooden boxes (with partitioned inner lining for impact protection)

- Labeling specifications:

- Boxes are printed with EN standard numbers, pressure ratings (PN10/16/25), dimensions, and corrosion protection type

- Hot-dip galvanized products have moisture-proof labels added to the outer boxes

Available size

Size | L | Bolting for mating flange | Flanged end | |||

Inch | DN | mm | mm | PCD (mm) | Bolt |

|

1″ | 25 | 33.7 | 61 | 85 | 4 × M12 | PN 16 |

1-1/4″ | 32 | 42.4 | 61 | 100 | 4 × M16 | PN 16 |

1-1/2″ | 40 | 48.3 | 61 | 110 | 4 × M16 | PN 16 |

2″ | 50 | 60.3 | 61 | 125 | 4 × M16 | PN 16 |

2-1/2″ | 65 | 73.0 | 61 | 145 | 4 × M16 | PN 16 |

2-1/2″ | 65 | 76.1 | 61 | 145 | 4 × M16 | PN 16 |

3″ | 80 | 88.9 | 65 | 160 | 8 × M16 | PN 16 |

4″ | 100 | 114.3 | 70 | 180 | 8 × M16 | PN 16 |

5″ | 125 | 139.7 | 70 | 210 | 8 × M16 | PN 16 |

6″ | 150 | 165.1 | 70 | 240 | 8 × M20 | PN 16 |

6″ | 150 | 168.3 | 70 | 240 | 8 × M20 | PN 16 |

8″ | 200 | 219.1 | 80 | 295 | 12 × M20 | PN 16 |

10″ | 250 | 273.0 | 85 | 355 | 12 × M24 | PN 16 |

12″ | 300 | 323.9 | 90 | 410 | 12 × M24 | PN 16 |

8″ | 200 | 219.1 | 80 | 295 | 8 × M20 | PN 10 |

10″ | 250 | 273.0 | 85 | 350 | 12 × M20 | PN 10 |

12″ | 300 | 323.9 | 90 | 400 | 12 × M20 | PN 10 |

2-1/2″ | 65 | 76.1 | 65 | 145 | 8 × M16 | PN 25 |

3″ | 80 | 88.9 | 65 | 160 | 8 × M16 | PN 25 |

4″ | 100 | 114.3 | 70 | 190 | 8 × M20 | PN 25 |

6″ | 150 | 165.1 | 70 | 250 | 8 × M24 | PN 25 |

8″ | 200 | 219.1 | 80 | 310 | 12 × M24 | PN 25 |

10″ | 250 | 273.0 | 85 | 370 | 12 × M27 | PN 25 |

12″ | 300 | 323.9 | 88 | 430 | 16 × M27 | PN 25 |

14″ | 350 | 355.6 | 100 | 490 | 16 × M30 | PN 25 |

16″ | 400 | 406.4 | 110 | 550 | 16 × M33 | PN 25 |

- Industrial Energy Systems:Power plant steam pipes, nuclear power plant cooling water systems,

- Flange transitions for oil and gas transmission pipelines on offshore platforms.

- Municipal and Building Facilities:Fire sprinkler systems compliant with European standards (UL/FM certified),District heating pipes, hospital/laboratory water supply and drainage systems.

- Process Industries:

- Chemical acid and alkali medium transportation,Sanitary-grade pipeline connections for the food and beverage industry.

- Special Environments:Ship ballast water pipelines (PN16 pressure rating),Flange conversion interfaces for pumps and valves in wastewater treatment plants.

- European Standard Compatible: EN 1092-2 flange ends, PN10/PN16/PN25 pressure ratings to meet European projects.

- High Pressure Use: 500psi (PN25) maximum pressure rating, perfect for all high-pressure industrial plumbing.

- Sizes Available by Pressure Rating (e.g., PN16 –1-12, PN25–2.5- 16), Precisely Matching Engineering Specifications

- Fast Installation: By using the groove connection, so welding be avoided and easy installation finish; with ductile iron material make sure long operation life.

- Corrosion Resistance and Durability – Red paint/hot-dip galvanized dual surface treatment options to suit different corrosive environment needs (e.g. Maritime climates, chemical workshops etc.) .

- Single-item protection: Double-layered packaging with bubble wrap and anti-rust paper, with protective film applied to the flange surface.

- Complete packaging solution:

- PN10/PN16 small-sized products are packaged in corrugated cardboard boxes (20 pieces per box)

- PN25 large-sized products use custom wooden boxes (with partitioned inner lining for impact protection)

- Labeling specifications:

- Boxes are printed with EN standard numbers, pressure ratings (PN10/16/25), dimensions, and corrosion protection type

- Hot-dip galvanized products have moisture-proof labels added to the outer boxes

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.