HOT PRODUCTS TAGS

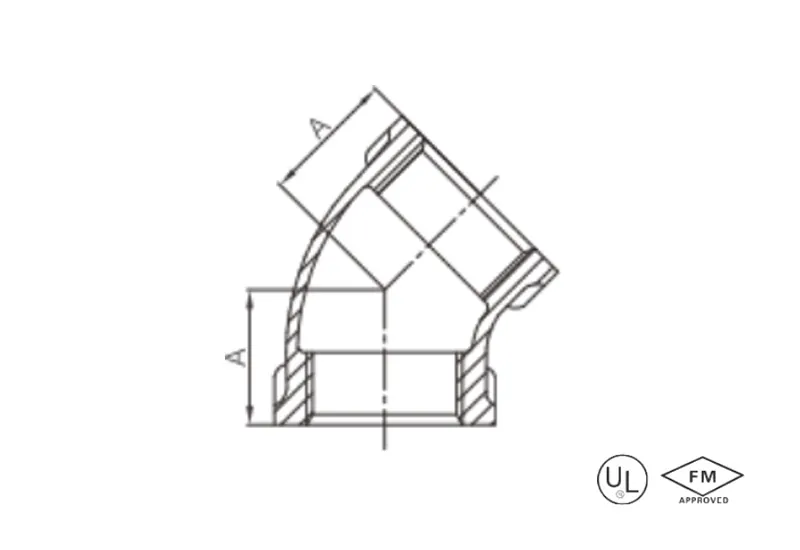

Malleable cast iron 45° elbow

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/4″-6″

description

Malleable cast iron 45° elbow, with high strength and good toughness, enables smooth pipeline turning.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 13.5 |

3/8″ | 10 | 17.2 | 17.2 |

1/2″ | 15 | 21.3 | 21.3 |

3/4″ | 20 | 26.9 | 26.9 |

1″ | 25 | 33.7 | 33.7 |

1-1/4″ | 32 | 42.4 | 42.4 |

1-1/2″ | 40 | 48.3 | 48.3 |

2″ | 50 | 60.3 | 60.3 |

2-1/2″ | 65 | 76.1 | 76.1 |

3″ | 80 | 88.9 | 88.9 |

4″ | 100 | 114.3 | 114.3 |

6″ | 150 | 165.1 | 165.1 |

Note: NSF 61 certificate is available for M0501, M0502, M0513.

application

- Long-distance pipeline network: Reduce flow loss and increase pump life span.

- HVAC systems: Create angled turns that save fluid power in chilled water pipes.

- Industrial equipment positioning: Angled low-resistance connections of the intake and exhaust pipes for compressors.

- Fire protection pipeline: UL/FM fire fighting system, sealed angled turn guarantee in sprinkler systems

- Fire-fighting pipeworks: to make the leak-tight 90-degree branches and T branch joints up to 355 mm with a higher efficiency.

- Low-angle pipe turns in engine room areas where ship power piping is limited.

- Agricultural irrigation systems: angled branch connections for large flowmeters at main pipelines by the pump stations.

- Long-distance energy pipelines: 45-degree bend in the pipe for lower pressure drop and vortex energy loss (for oil & gas)

- Municipal water supply distribution system: Branch connections with angles to be applied in main pipeline in order to decrease the risks of impacts of water hammer .

advantages

- Fluid dynamics optimization: The 45° angled design reduces pressure loss by 40% compared to a 90° elbow.

- High-pressure sealing assurance: Zero leakage operation under 25 bar conditions with BSPT tapered threads.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists salt spray and chemical medium corrosion.

- Wide temperature range stability: Maintains material structural integrity from -30°C to 120°C.

- Dual international certifications: Certified by UL/FM for fire safety and NSF 61 (coveringmodelsM0501/M0502/M0513).

- Impact-resistant reinforcement: Ductile iron base enhances water hammer impact resistance by 3 times.

- Compact layout compatibility: Angled structure saves 25% of turning space.

- Installation precision control: Machined threads ensure precise axial alignment of pipes.

packing

- Curved corner protective padding: Custom PE foam molded to fit 45° sloped surfaces for cushioning.

- Threaded end dual protection: Inset injection-molded cap + outer rust-proof sealing tape.

- Full-surface armor wrapping: Wrapped bubble column bags + anti-static film sealing.

- Smart sorting and packing: Laser-cut foam boards secured in place by inch-sized slots.

- Angled flow direction indicators: 45° fluid direction arrows printed on the outer box.

- Load-bearing grading scheme: ≤2“ uses five-layer corrugated boxes / ≥3” uses steel-banded wooden boxes.

- Certified specialized management: NSF-certified models are labeled separately and accompanied by test reports.

- Anti-vibration traceability system: RFID chips embedded in the box body are linked to production data.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/4″ | 8 | 13.5 | 13.5 |

3/8″ | 10 | 17.2 | 17.2 |

1/2″ | 15 | 21.3 | 21.3 |

3/4″ | 20 | 26.9 | 26.9 |

1″ | 25 | 33.7 | 33.7 |

1-1/4″ | 32 | 42.4 | 42.4 |

1-1/2″ | 40 | 48.3 | 48.3 |

2″ | 50 | 60.3 | 60.3 |

2-1/2″ | 65 | 76.1 | 76.1 |

3″ | 80 | 88.9 | 88.9 |

4″ | 100 | 114.3 | 114.3 |

6″ | 150 | 165.1 | 165.1 |

Note: NSF 61 certificate is available for M0501, M0502, M0513.

- Long-distance pipeline network: Reduce flow loss and increase pump life span.

- HVAC systems: Create angled turns that save fluid power in chilled water pipes.

- Industrial equipment positioning: Angled low-resistance connections of the intake and exhaust pipes for compressors.

- Fire protection pipeline: UL/FM fire fighting system, sealed angled turn guarantee in sprinkler systems

- Fire-fighting pipeworks: to make the leak-tight 90-degree branches and T branch joints up to 355 mm with a higher efficiency.

- Low-angle pipe turns in engine room areas where ship power piping is limited.

- Agricultural irrigation systems: angled branch connections for large flowmeters at main pipelines by the pump stations.

- Long-distance energy pipelines: 45-degree bend in the pipe for lower pressure drop and vortex energy loss (for oil & gas)

- Municipal water supply distribution system: Branch connections with angles to be applied in main pipeline in order to decrease the risks of impacts of water hammer .

- Fluid dynamics optimization: The 45° angled design reduces pressure loss by 40% compared to a 90° elbow.

- High-pressure sealing assurance: Zero leakage operation under 25 bar conditions with BSPT tapered threads.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists salt spray and chemical medium corrosion.

- Wide temperature range stability: Maintains material structural integrity from -30°C to 120°C.

- Dual international certifications: Certified by UL/FM for fire safety and NSF 61 (coveringmodelsM0501/M0502/M0513).

- Impact-resistant reinforcement: Ductile iron base enhances water hammer impact resistance by 3 times.

- Compact layout compatibility: Angled structure saves 25% of turning space.

- Installation precision control: Machined threads ensure precise axial alignment of pipes.

- Curved corner protective padding: Custom PE foam molded to fit 45° sloped surfaces for cushioning.

- Threaded end dual protection: Inset injection-molded cap + outer rust-proof sealing tape.

- Full-surface armor wrapping: Wrapped bubble column bags + anti-static film sealing.

- Smart sorting and packing: Laser-cut foam boards secured in place by inch-sized slots.

- Angled flow direction indicators: 45° fluid direction arrows printed on the outer box.

- Load-bearing grading scheme: ≤2“ uses five-layer corrugated boxes / ≥3” uses steel-banded wooden boxes.

- Certified specialized management: NSF-certified models are labeled separately and accompanied by test reports.

- Anti-vibration traceability system: RFID chips embedded in the box body are linked to production data.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.