HOT PRODUCTS TAGS

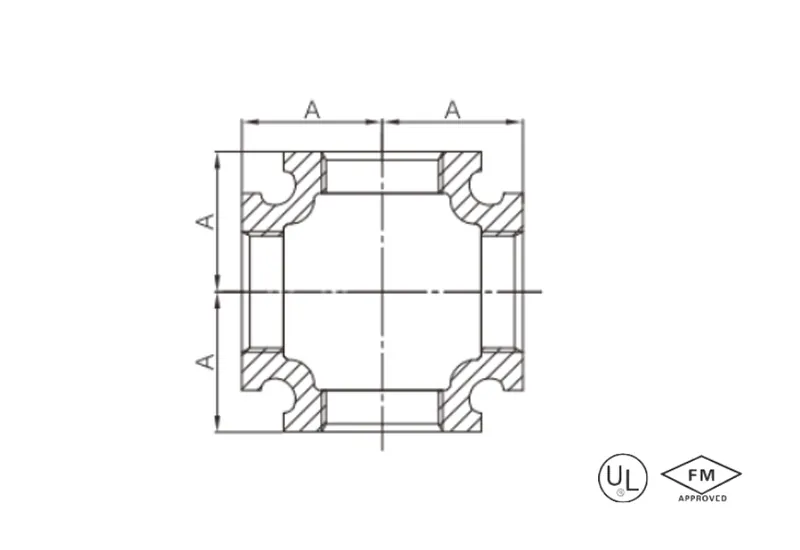

Malleable cast iron equal cross

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″—4″

description

Malleable cast iron equal cross, balanced four – way flow division, stable connection, corrosion resistant, wear – resistant, suitable for complex pipelines.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 28 |

3/4″ | 20 | 26.9 | 33 |

1″ | 25 | 33.7 | 38 |

1-1/4″ | 32 | 42.4 | 45 |

1-1/2″ | 40 | 48.3 | 50 |

2″ | 50 | 60.3 | 58 |

2-1/2″ | 65 | 76.1 | 69 |

3″ | 80 | 88.9 | 78 |

4″ | 100 | 114.3 | 96 |

Note: NSF 61 certificate is available for M1903 ~ M1911, except M1906.

application

- Chemical reaction matrix: Four-way equal-diameter diversion ensures synchronous and balanced distribution of reaction media.

- Central air conditioning hub: Cross-shaped equal-diameter design in the chilled water system ensures balanced pressure across multiple terminals.

- Fire protection network core: UL-certified four-way equal-pressure output supports simultaneous activation of multiple sprinkler branches.

- Ship integrated piping system: Engine room fuel/freshwater four-way symmetrical diversion control system.

- Agricultural Irrigation Network: Pump station main pipeline four-way equal-diameter output matches square irrigation blocks.

- Industrial Cooling System: Reactor circulating water cross-shaped equal-diameter diversion achieves temperature field equilibrium.

- Municipal Water Supply Node: Main road four-way equal-diameter connection between new and old pipelines achieves zero pressure loss.

- Energy Monitoring Network: Oil and gas pipeline cross-shaped equal-diameter sampling ports synchronously obtain data from all four directions.

advantages

- Four-dimensional flow balancing: Cross-shaped equal-diameter structure achieves zero flow deviation distribution.

- High-pressure sealing matrix: 25 bar operating conditions with four-way BSPT tapered threads for synchronized zero leakage.

- Fully symmetrical stress field: Malleable cast iron base uniformly distributes four-way pressure peaks.

- NSF safety certification: Drinking water-grade galvanized coating prevents heavy metal ion leaching.

- Heavy-Duty Structural Reinforcement: 4-inch bore maintains zero deformation at 25 bar pressure.

- Full Environmental Corrosion Resistance: Hot-dip galvanized coating resists corrosion from seawater and chemical media.

- Installation Efficiency Revolution: Single component replaces three-way + straight-through assemblies, reducing leakage points by 80%.

- Wide Temperature Range Stability: Maintains four-way structural integrity under extreme conditions from -30°C to 120°C.

packing

- Cross-port protection: Four-way injection-molded cover with threaded ports + end-face sealing ring.

- Three-dimensional cushioning structure: EPE pearl cotton molded cross-flow channels with curved surface adhesion.

- Anti-corrosion armor system: Vapor-phase anti-corrosion film + moisture-proof paper composite vacuum wrapping.

- Anti-error positioning design: Laser-cut pine wood cross-shaped support frame for precise positioning and fixation.

- Ultra-high load-bearing solution: Steel-reinforced fumigated wooden box (compatible with DN100 load-bearing capacity).

- Holographic traceability management: Box body laser code linked to NSF certification + pressure parameters.

- Anti-rolling structure: Inner box cross steel frame locks four-way transportation with zero displacement.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

1/2″ | 15 | 21.3 | 28 |

3/4″ | 20 | 26.9 | 33 |

1″ | 25 | 33.7 | 38 |

1-1/4″ | 32 | 42.4 | 45 |

1-1/2″ | 40 | 48.3 | 50 |

2″ | 50 | 60.3 | 58 |

2-1/2″ | 65 | 76.1 | 69 |

3″ | 80 | 88.9 | 78 |

4″ | 100 | 114.3 | 96 |

Note: NSF 61 certificate is available for M1903 ~ M1911, except M1906.

- Chemical reaction matrix: Four-way equal-diameter diversion ensures synchronous and balanced distribution of reaction media.

- Central air conditioning hub: Cross-shaped equal-diameter design in the chilled water system ensures balanced pressure across multiple terminals.

- Fire protection network core: UL-certified four-way equal-pressure output supports simultaneous activation of multiple sprinkler branches.

- Ship integrated piping system: Engine room fuel/freshwater four-way symmetrical diversion control system.

- Agricultural Irrigation Network: Pump station main pipeline four-way equal-diameter output matches square irrigation blocks.

- Industrial Cooling System: Reactor circulating water cross-shaped equal-diameter diversion achieves temperature field equilibrium.

- Municipal Water Supply Node: Main road four-way equal-diameter connection between new and old pipelines achieves zero pressure loss.

- Energy Monitoring Network: Oil and gas pipeline cross-shaped equal-diameter sampling ports synchronously obtain data from all four directions.

- Four-dimensional flow balancing: Cross-shaped equal-diameter structure achieves zero flow deviation distribution.

- High-pressure sealing matrix: 25 bar operating conditions with four-way BSPT tapered threads for synchronized zero leakage.

- Fully symmetrical stress field: Malleable cast iron base uniformly distributes four-way pressure peaks.

- NSF safety certification: Drinking water-grade galvanized coating prevents heavy metal ion leaching.

- Heavy-Duty Structural Reinforcement: 4-inch bore maintains zero deformation at 25 bar pressure.

- Full Environmental Corrosion Resistance: Hot-dip galvanized coating resists corrosion from seawater and chemical media.

- Installation Efficiency Revolution: Single component replaces three-way + straight-through assemblies, reducing leakage points by 80%.

- Wide Temperature Range Stability: Maintains four-way structural integrity under extreme conditions from -30°C to 120°C.

- Cross-port protection: Four-way injection-molded cover with threaded ports + end-face sealing ring.

- Three-dimensional cushioning structure: EPE pearl cotton molded cross-flow channels with curved surface adhesion.

- Anti-corrosion armor system: Vapor-phase anti-corrosion film + moisture-proof paper composite vacuum wrapping.

- Anti-error positioning design: Laser-cut pine wood cross-shaped support frame for precise positioning and fixation.

- Ultra-high load-bearing solution: Steel-reinforced fumigated wooden box (compatible with DN100 load-bearing capacity).

- Holographic traceability management: Box body laser code linked to NSF certification + pressure parameters.

- Anti-rolling structure: Inner box cross steel frame locks four-way transportation with zero displacement.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.