HOT PRODUCTS TAGS

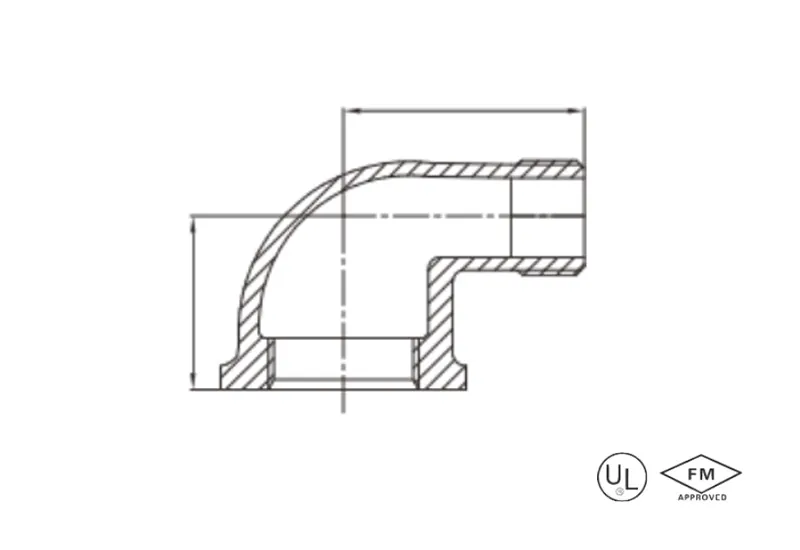

Malleable cast iron male and female 90° reducing elbow

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1″ x 3/4″ -1-1/4″ x 1″

description

Malleable cast iron male and female 90° reducing elbow, fitting different pipe diameters, with firm connection and smooth turning.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 35 | 46 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 40 | 56 |

Note: NSF 61 certificate is available for M0414, M0418.

application

- Industrial equipment layout: Right-angle transition seals for connections between compressor inlet and outlet pipes of different diameters.

- HVAC systems: Variable-diameter right-angle hard connections between chilled water main pipes and small terminal devices.

- Fire protection network renovation: UL/FM-certified connections for variable-diameter transitions between new and old pipes in sprinkler systems.

- Ship power piping: Simultaneous implementation of variable-diameter transitions and right-angle turns for metal pipes within engine room spaces.

- Building water supply upgrade: Leak-proof right-angle transition for different diameter connections between main and branch pipes.

- Energy detection interfaces: Pressure-resistant different diameter right-angle connections for detection ports on oil and gas transmission pipelines.

- Agricultural irrigation hubs: Pressure-resistant right-angle connections for different diameter main and field branch pipes in pump rooms.

- Municipal maintenance nodes: Sealed right-angle connections for different diameter maintenance ports on water supply pipelines.

advantages

- Three-in-one integrated design: combined 90° turning + diameter change at the same time to directly connect internal / external thread.

- High Pressure Sealing Guarantee: Zero Leak When BSPT Tapered Thread is Double Sealed at 25 bar.

- All-environmental corrosion resistance: When hot-dip galvanizing coated, it will not corrode in seawater/chemical medium(at least the outdoor life is three times higher).

- Compact structure innovation: Saves 50% installation space with respect to traditional components.

- Dual international certifications (UL/FM fire safety, NSF 61 water quality) [available with M0414 and M0418 models]

- Vibration resistant design: Forged cast iron base with machined threads delivers long-term performance reliability.

- Great Range of Temperatures: From -30°C to 120°, it will keep its shape and support.

- Improved installation efficiency: Single-piece design replaces multiple component connections, which reduces potential leakage areas.

packing

- Differential protection for different diameters: dual protection with a large-diameter injection-molded cap and a small-diameter metal sleeve.

- Curved surface cushioning system: high-resilience EPE pearl cotton molded wrapping around 90° corners.

- Full-surface scratch-resistant layer: vapor-phase anti-rust film + wrapped bubble column bag sealed wrapping.

- Anti-misalignment packaging: laser-cut foam boards precisely positioned and secured according to size.

- Dual-color flow direction indicators: Red flow direction arrows and diameter change direction (large diameter → small diameter) printed on the outer box.

- Certification-specific labeling: NSF-certified models with separate labels and copies of certification documents.

- Customized load-bearing solutions: Steel-reinforced wooden boxes (box load-bearing capacity ≥ 1.5 tons).

- Smart traceability management: Box laser anti-counterfeiting codes linked to production batches and certification documents.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 35 | 46 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 40 | 56 |

Note: NSF 61 certificate is available for M0414, M0418.

- Industrial equipment layout: Right-angle transition seals for connections between compressor inlet and outlet pipes of different diameters.

- HVAC systems: Variable-diameter right-angle hard connections between chilled water main pipes and small terminal devices.

- Fire protection network renovation: UL/FM-certified connections for variable-diameter transitions between new and old pipes in sprinkler systems.

- Ship power piping: Simultaneous implementation of variable-diameter transitions and right-angle turns for metal pipes within engine room spaces.

- Building water supply upgrade: Leak-proof right-angle transition for different diameter connections between main and branch pipes.

- Energy detection interfaces: Pressure-resistant different diameter right-angle connections for detection ports on oil and gas transmission pipelines.

- Agricultural irrigation hubs: Pressure-resistant right-angle connections for different diameter main and field branch pipes in pump rooms.

- Municipal maintenance nodes: Sealed right-angle connections for different diameter maintenance ports on water supply pipelines.

- Three-in-one integrated design: combined 90° turning + diameter change at the same time to directly connect internal / external thread.

- High Pressure Sealing Guarantee: Zero Leak When BSPT Tapered Thread is Double Sealed at 25 bar.

- All-environmental corrosion resistance: When hot-dip galvanizing coated, it will not corrode in seawater/chemical medium(at least the outdoor life is three times higher).

- Compact structure innovation: Saves 50% installation space with respect to traditional components.

- Dual international certifications (UL/FM fire safety, NSF 61 water quality) [available with M0414 and M0418 models]

- Vibration resistant design: Forged cast iron base with machined threads delivers long-term performance reliability.

- Great Range of Temperatures: From -30°C to 120°, it will keep its shape and support.

- Improved installation efficiency: Single-piece design replaces multiple component connections, which reduces potential leakage areas.

- Differential protection for different diameters: dual protection with a large-diameter injection-molded cap and a small-diameter metal sleeve.

- Curved surface cushioning system: high-resilience EPE pearl cotton molded wrapping around 90° corners.

- Full-surface scratch-resistant layer: vapor-phase anti-rust film + wrapped bubble column bag sealed wrapping.

- Anti-misalignment packaging: laser-cut foam boards precisely positioned and secured according to size.

- Dual-color flow direction indicators: Red flow direction arrows and diameter change direction (large diameter → small diameter) printed on the outer box.

- Certification-specific labeling: NSF-certified models with separate labels and copies of certification documents.

- Customized load-bearing solutions: Steel-reinforced wooden boxes (box load-bearing capacity ≥ 1.5 tons).

- Smart traceability management: Box laser anti-counterfeiting codes linked to production batches and certification documents.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.