HOT PRODUCTS TAGS

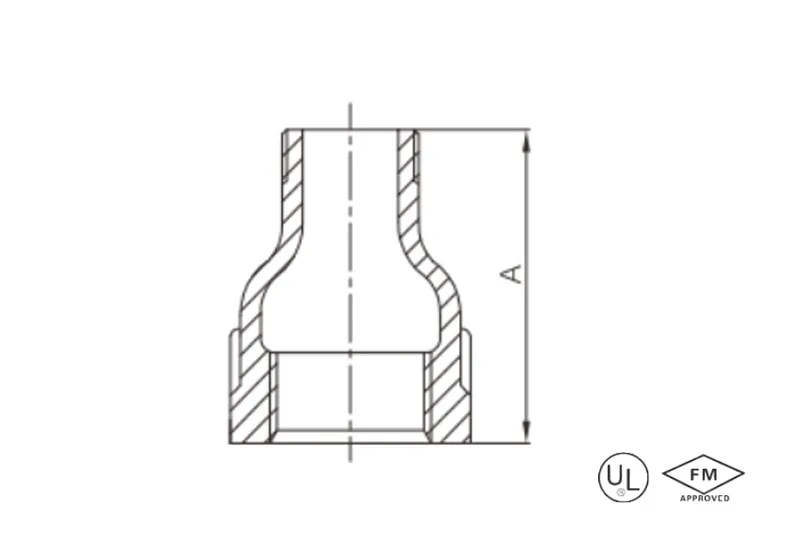

Malleable cast iron male and female reducing socket

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 3/8″ x 1/4″—2″ x 1-1/2″

description

Malleable cast iron male and female reducing socket, precise diameter-changing butt joint, sturdy, pressure-resistant, suitable for various pipe types.

Specification

Available size

SIZE | A | ||

INCH | DN | MM | MM |

3/8″ x 1/4″ | 10 x 8 | 17.2 x 13.5 | 35 |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.5 | 43 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 43 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.2 | 48 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 48 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 55 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 55 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 60 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 60 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 60 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 63 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 63 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 63 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 70 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 70 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 70 |

Note: NSF 61 certificate is available for M2506 ~ M2531, except M2503, M2505.

application

- Pipeline Renovation Project: Different diameter internal and external thread design enables quick sealing and connection of new and old pipelines.

- Fire Protection System Maintenance: UL-certified variable diameter connection ensures high-pressure, leak-free renovation of sprinkler pipe networks.

- Ship Engine Room Maintenance: Quick repair connection of fuel/cooling water pipes with different diameters in confined spaces.

- Municipal Water Conservation Renovation: Water-saving connection of large-diameter main pipelines and old branch pipelines without welding.

- Industrial Equipment Integration: Eliminate flange connection leakage risks in compressor inlet/outlet pipes with different diameters.

- Agricultural Irrigation Upgrades: Rapidly extend main pipeline and branch pipeline connections with different diameters at pump stations.

- Mining Pipeline Emergency: High wear resistance to withstand impact in slurry transportation pipelines with different diameters.

- Chemical Instrument Installation: Micro-sized pipes with different diameters achieve seamless connection between instrument pipelines and main processes.

advantages

- Dual-thread high-pressure seal: 25 bar operating conditions with BSPT tapered threads ensure zero leakage in both directions.

- NSF safety certification: Specific models feature a zinc-plated layer for drinking water applications, eliminating the risk of heavy metal leaching.

- Compact variable-diameter design: The integrated internal and external thread design saves 70% installation space compared to traditional components.

- Fluid-Friendly Transition: Conical flow channels reduce pressure loss in the reducer section to one-quarter of traditional structures.

- Armor-Grade Dual Protection System: Hot-dip galvanized coating passes 3,600-hour industrial acid/alkali and salt spray dual testing.

- Enhanced vibration resistance: Thickened eccentric wall design improves mechanical impact resistance by 45%.

- Installation efficiency boost: Single-piece replacement of union fittings and double pipe clamps saves 85% of installation time.

- Precision size coverage: 1/4“ to 2” diameter range accommodates modifications from instrumentation microtubes to industrial main pipelines.

packing

- Asymmetric Cushioning System: EPE pearl cotton molded uneven curved surface adaptive wrapping.

- Anti-corrosion armor layer: vapor-phase anti-corrosion film + moisture-proof aluminum foil vacuum composite sealing.

- Anti-misalignment positioning structure: laser-cut pine wood irregular track-style slots for precise fitting.

- Heavy-duty load-bearing solution: steel-reinforced fumigated wooden box (compatible with DN50 load-bearing capacity).

- Zero-displacement design: inner box cross steel frame locking tube clamps for transportation stability.

Available size

SIZE | A | ||

INCH | DN | MM | MM |

3/8″ x 1/4″ | 10 x 8 | 17.2 x 13.5 | 35 |

1/2″ x 1/4″ | 15 x 8 | 21.3 x 13.5 | 43 |

1/2″ x 3/8″ | 15 x 10 | 21.3 x 17.2 | 43 |

3/4″ x 3/8″ | 20 x 10 | 26.7 x 17.2 | 48 |

3/4″ x 1/2″ | 20 x 15 | 26.7 x 21.3 | 48 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 55 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 55 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 60 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 60 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 60 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 63 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 63 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 63 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 70 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 70 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 70 |

Note: NSF 61 certificate is available for M2506 ~ M2531, except M2503, M2505.

- Pipeline Renovation Project: Different diameter internal and external thread design enables quick sealing and connection of new and old pipelines.

- Fire Protection System Maintenance: UL-certified variable diameter connection ensures high-pressure, leak-free renovation of sprinkler pipe networks.

- Ship Engine Room Maintenance: Quick repair connection of fuel/cooling water pipes with different diameters in confined spaces.

- Municipal Water Conservation Renovation: Water-saving connection of large-diameter main pipelines and old branch pipelines without welding.

- Industrial Equipment Integration: Eliminate flange connection leakage risks in compressor inlet/outlet pipes with different diameters.

- Agricultural Irrigation Upgrades: Rapidly extend main pipeline and branch pipeline connections with different diameters at pump stations.

- Mining Pipeline Emergency: High wear resistance to withstand impact in slurry transportation pipelines with different diameters.

- Chemical Instrument Installation: Micro-sized pipes with different diameters achieve seamless connection between instrument pipelines and main processes.

- Dual-thread high-pressure seal: 25 bar operating conditions with BSPT tapered threads ensure zero leakage in both directions.

- NSF safety certification: Specific models feature a zinc-plated layer for drinking water applications, eliminating the risk of heavy metal leaching.

- Compact variable-diameter design: The integrated internal and external thread design saves 70% installation space compared to traditional components.

- Fluid-Friendly Transition: Conical flow channels reduce pressure loss in the reducer section to one-quarter of traditional structures.

- Armor-Grade Dual Protection System: Hot-dip galvanized coating passes 3,600-hour industrial acid/alkali and salt spray dual testing.

- Enhanced vibration resistance: Thickened eccentric wall design improves mechanical impact resistance by 45%.

- Installation efficiency boost: Single-piece replacement of union fittings and double pipe clamps saves 85% of installation time.

- Precision size coverage: 1/4“ to 2” diameter range accommodates modifications from instrumentation microtubes to industrial main pipelines.

- Asymmetric Cushioning System: EPE pearl cotton molded uneven curved surface adaptive wrapping.

- Anti-corrosion armor layer: vapor-phase anti-corrosion film + moisture-proof aluminum foil vacuum composite sealing.

- Anti-misalignment positioning structure: laser-cut pine wood irregular track-style slots for precise fitting.

- Heavy-duty load-bearing solution: steel-reinforced fumigated wooden box (compatible with DN50 load-bearing capacity).

- Zero-displacement design: inner box cross steel frame locking tube clamps for transportation stability.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.