HOT PRODUCTS TAGS

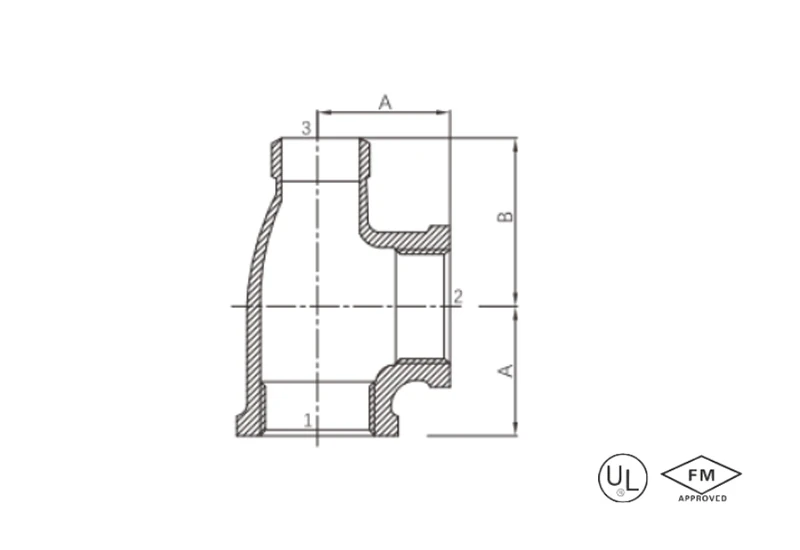

Malleable cast iron reducing service tee

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 2″ x 1-1/2″ x 2″—3″ x 2-1/2″ x 3″

description

Malleable cast iron reducing service tee, efficient flow division, fits unequal pipes, tough, durable and easy to install.

Specification

Available size

| SIZE(1 x 3 x 2) | A | B | ||

| INCH | DN | MM | MM | MM |

| 2″ x 1-1/2″ x 2″ | 50 x 40 x 50 | 60.3 x 48.3 x 60.3 | 57 | 75 |

| 2-1/2″ x 2″ x 2-1/2″ | 65 x 50 x 65 | 76.1 x 60.3 x 76.1 | 69 | 88 |

| 3″ x 2-1/2″ x 3″ | 80 x 65 x 80 | 88.9 x 76.1 x 88.9 | 78 | 106 |

application

- Industrial Pipeline Hub: Main pipelines are designed with the same diameter to ensure stable main flow, while branch pipelines with different diameters enable precise diversion.

- Energy Transmission Trunk Line: Large-diameter variable-diameter synchronous sampling at oil and gas pipeline inspection ports.

- Ship Power System: Variable-diameter diversion control for main fuel/cooling water pipelines in the engine room.

- Municipal Water Supply Upgrade: Large-diameter main pipelines connected to branch pipelines for water-saving renovations.

- Industrial Cooling Matrix: Multi-stage variable-diameter temperature control for reactor circulating water systems.

- Fire Protection System Expansion: UL-certified high-flow sprinkler pipeline networks with mixed connections via variable-diameter fittings.

- Agricultural Irrigation Hub: Pump station main pipelines with stepped variable-diameter fittings to match large-scale irrigation areas.

- Mining Pipeline Network: High-wear-resistant characteristics adapted for slurry transportation branch line diversion.

advantages

- Dual main pipe with equal diameter stability: The main pipe is designed with equal diameters at both ends to eliminate turbulent disturbances.

- Precise branch pipe diameter change: The asymmetric flow channel optimizes the distribution efficiency of high-flow media.

- Industrial-grade pressure-resistant core: Triple BSPT thread sealing for 25 bar high-pressure conditions.

- Armor-grade protection system: Hot-dip galvanized coating resists corrosion in acidic, alkaline, and high-humidity environments.

- Stress dual-track decomposition: Forged cast iron base simultaneously dissipates pressure peaks in the main and branch pipes.

- Heavy-duty structural reinforcement: 50% improvement in mechanical impact resistance compared to standard components.

- Revolutionary installation breakthrough: Single-piece replacement for flange assemblies + variable-diameter pipes, saving 75% of installation time.

- Full temperature range reliability: Zero structural deformation under extreme conditions from -30°C to 120°C.

packing

- Stepped port protection: Three-size injection-molded caps with nested threads + end-face sealing.

- Heavy-duty cushioning system: EPE pearl cotton molded and bonded to the main pipe/branch pipe surfaces.

- Fully sealed armor layer: vapor-phase rust-proof film + honeycomb steel plate composite wrapping.

- Load-bearing anti-error structure: laser-cut pine wood brackets three-dimensionally fitted to size.

- Ultra-strong transportation fortress: steel-band reinforced fumigated wooden box (load-bearing capacity ≥ 3 tons).

- Holographic traceability management: Laser codes on the box body linked to pressure ratings and diameter change parameters.

- Impact-resistant structure: I-beam steel frame inner box locking three-way fittings with zero displacement.

Available size

| SIZE(1 x 3 x 2) | A | B | ||

| INCH | DN | MM | MM | MM |

| 2″ x 1-1/2″ x 2″ | 50 x 40 x 50 | 60.3 x 48.3 x 60.3 | 57 | 75 |

| 2-1/2″ x 2″ x 2-1/2″ | 65 x 50 x 65 | 76.1 x 60.3 x 76.1 | 69 | 88 |

| 3″ x 2-1/2″ x 3″ | 80 x 65 x 80 | 88.9 x 76.1 x 88.9 | 78 | 106 |

- Industrial Pipeline Hub: Main pipelines are designed with the same diameter to ensure stable main flow, while branch pipelines with different diameters enable precise diversion.

- Energy Transmission Trunk Line: Large-diameter variable-diameter synchronous sampling at oil and gas pipeline inspection ports.

- Ship Power System: Variable-diameter diversion control for main fuel/cooling water pipelines in the engine room.

- Municipal Water Supply Upgrade: Large-diameter main pipelines connected to branch pipelines for water-saving renovations.

- Industrial Cooling Matrix: Multi-stage variable-diameter temperature control for reactor circulating water systems.

- Fire Protection System Expansion: UL-certified high-flow sprinkler pipeline networks with mixed connections via variable-diameter fittings.

- Agricultural Irrigation Hub: Pump station main pipelines with stepped variable-diameter fittings to match large-scale irrigation areas.

- Mining Pipeline Network: High-wear-resistant characteristics adapted for slurry transportation branch line diversion.

- Dual main pipe with equal diameter stability: The main pipe is designed with equal diameters at both ends to eliminate turbulent disturbances.

- Precise branch pipe diameter change: The asymmetric flow channel optimizes the distribution efficiency of high-flow media.

- Industrial-grade pressure-resistant core: Triple BSPT thread sealing for 25 bar high-pressure conditions.

- Armor-grade protection system: Hot-dip galvanized coating resists corrosion in acidic, alkaline, and high-humidity environments.

- Stress dual-track decomposition: Forged cast iron base simultaneously dissipates pressure peaks in the main and branch pipes.

- Heavy-duty structural reinforcement: 50% improvement in mechanical impact resistance compared to standard components.

- Revolutionary installation breakthrough: Single-piece replacement for flange assemblies + variable-diameter pipes, saving 75% of installation time.

- Full temperature range reliability: Zero structural deformation under extreme conditions from -30°C to 120°C.

- Stepped port protection: Three-size injection-molded caps with nested threads + end-face sealing.

- Heavy-duty cushioning system: EPE pearl cotton molded and bonded to the main pipe/branch pipe surfaces.

- Fully sealed armor layer: vapor-phase rust-proof film + honeycomb steel plate composite wrapping.

- Load-bearing anti-error structure: laser-cut pine wood brackets three-dimensionally fitted to size.

- Ultra-strong transportation fortress: steel-band reinforced fumigated wooden box (load-bearing capacity ≥ 3 tons).

- Holographic traceability management: Laser codes on the box body linked to pressure ratings and diameter change parameters.

- Impact-resistant structure: I-beam steel frame inner box locking three-way fittings with zero displacement.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.