HOT PRODUCTS TAGS

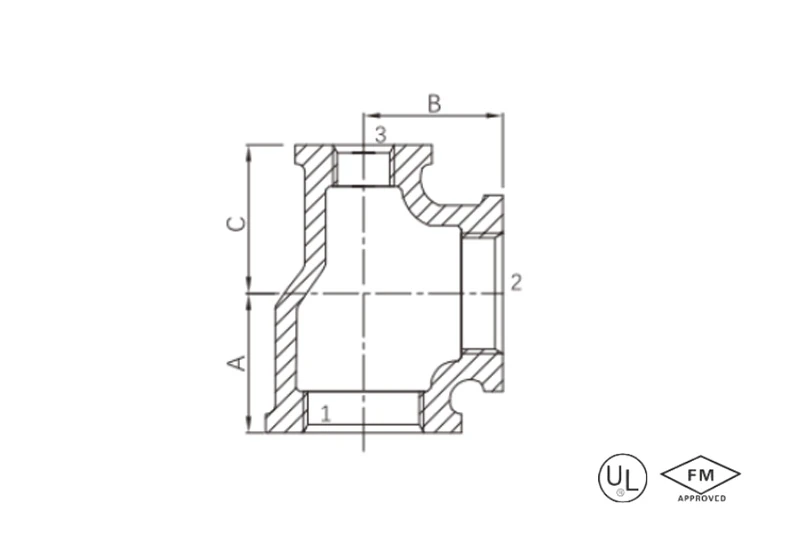

Malleable cast iron reducing tee (Equal major run and branch)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 3/4″ x 1/2″ x 3/4″—2-1/2″ x 2″ x 2-1/2″

description

Malleable cast iron reducing tee, strong, durable, equal design for versatility, easy to install.

Specification

Available size

SIZE(1 x 3 x 2) | A | B | C | ||

INCH | DN | MM | MM | MM | MM |

3/4″ x 1/2″ x 3/4″ | 20 x 15 x 20 | 26.9 x 21.3 x 26.9 | 33 | 33 | 31 |

1‘’ x 1/4‘’ x1‘’ | 25 x 8 x 25 | 33.7 x 13.7 x 33.7 | 38 | 38 | 30 |

1″ x 1/2″ x 1″ | 25 x 15 x 25 | 33.7 x 21.3 x 33.7 | 38 | 38 | 34 |

1″ x 3/4″ x 1″ | 25 x 20 x 25 | 33.7 x 26.9 x 33.7 | 38 | 38 | 36 |

1-1/4″ x 1/2″ x 1-1/4″ | 32 x 15 x 32 | 42.4 x 21.3 x 42.4 | 45 | 45 | 38 |

1-1/4″ x 3/4″ x 1-1/4″ | 32 x 20 x 32 | 42.4 x 26.9 x 42.4 | 45 | 45 | 41 |

1-1/4″ x 1″ x 1-1/4″ | 32 x 25 x 32 | 42.4 x 33.7 x 42.4 | 45 | 45 | 42 |

1-1/2″ x 1/2″ x 1-1/2″ | 40 x 15 x 40 | 48.3 x 21.3 x 48.3 | 50 | 50 | 42 |

1-1/2″ x 3/4″ x 1-1/2″ | 40 x 20 x 40 | 48.3 x 26.9 x 48.3 | 50 | 50 | 44 |

1-1/2″ x 1″ x 1-1/2″ | 40 x 25 x 40 | 48.3 x 33.7 x 48.3 | 50 | 50 | 46 |

1-1/2″ x 1-1/4″ x 1-1/2″ | 40 x 32 x 40 | 48.3 x 42.4 x 48.3 | 50 | 50 | 48 |

2″ x 1/2″ x 2″ | 50 x 15 x 50 | 60.3 x 21.3 x 60.3 | 58 | 58 | 48 |

2″ x 3/4″ x 2″ | 50 x 20 x 50 | 60.3 x 26.9 x 60.3 | 58 | 58 | 50 |

2″ x 1″ x 2″ | 50 x 25 x 50 | 60.3 x 33.7 x 60.3 | 58 | 58 | 52 |

2″ x 1-1/4″ x 2″ | 50 x 32 x 50 | 60.3 x 42.4 x 60.3 | 58 | 58 | 54 |

2″ x 1-1/2″ x 2″ | 50 x 40 x 50 | 60.3 x 48.3 x 60.3 | 58 | 58 | 55 |

2-1/2″ x 1-1/2″ x 2-1/2″ | 65 x 40 x 65 | 76.1 x 48.3 x 76.1 | 68 | 68 | 64 |

2-1/2″ x 2″ x 2-1/2″ | 65 x 50 x 65 | 76.1 x 60.3 x 76.1 | 68 | 68 | 65 |

Note: : NSF 61 certificate is available for M1310 ~ M1337, except M1311.

application

- Chemical mixing system: Main pipes of equal diameter maintain main line pressure, while branch pipes of varying diameters precisely add auxiliary materials.

- HVAC engineering: Chilled water main pipes deliver at equal pressure, while branch pipes of varying diameters adapt to different terminal equipment.

- Fire protection network upgrade: UL/FM certification ensures stable pressure in main pipes and throttling and diversion in branch pipes for sprinkler systems.

- Industrial Equipment Layout: compressor main pipes maintain equal diameter output, while branch pipes vary in diameter to connect to pressure gauges.

- Ship Ballast System: main pipes in the engine room maintain equal diameter water supply, while branch pipes vary in diameter to control compartment flow.

- Agricultural irrigation hubs: Main pipes in pump stations maintain equal pressure, while branch pipes vary in diameter to match different irrigation zones.

- Energy sampling networks: Main pipes in oil and gas pipelines maintain equal diameter for detection, while branch pipes vary in diameter for sampling diversion.

- Municipal water supply nodes: Main roads maintain equal pressure, while branch pipes vary in diameter to adapt to different district requirements.

advantages

- Main pipe equal diameter design: Ensures stable fluid pressure/flow throughout the main line.

- Triple high-pressure sealing: Zero leakage at 25 bar operating conditions with BSPT tapered threads (main pipe x2 + branch pipe x1).

- Precise fluid control: Tapered branch pipes enable flow distribution according to demand.

- Corrosion-resistant matrix: Hot-dip galvanized coating resists industrial exhaust fumes and marine salt spray corrosion.

- Dual international certifications: UL/FM fire safety and NSF 61 certification (applies to models M1310–M1337, excluding M1311).

- Impact-resistant reinforcement: Ductile iron base absorbs water hammer impacts from branch pipe diameter changes.

- Wide temperature range reliability: Maintains triple interface seal integrity from -30°C to 120°C.

- Installation efficiency innovation: Single unit achieves main pipe pressure regulation + branch pipe flow control, reducing components by 50%.

packing

- Equal-diameter port collaborative protection: dual main pipe injection-molded cover + branch pipe metal reducer sleeve.

- Asymmetric cushioning system: EPE pearl cotton molded and bonded to the main pipe’s equal-diameter flat surface + branch pipe reducer curved surface.

- Full-surface armor sealing: rust-proof oil impregnation + stretch film + bubble column triple protection.

- Precision positioning slots: laser-cut foam board fixed to the three-way interface according to dimensions.

- Flow direction identification system: Main pipe equal diameter arrow (→→) and branch pipe variable diameter symbol (▼) printed on the outer box.

- Load-bearing grading scheme: ≤1.5“ uses five-layer corrugated boxes/≥2” uses steel-band fumigated wooden boxes.

- Certification-specific labeling: NSF-certified models have independent labels (M1310~M1337, excluding M1311).

- Anti-Rolling Structure: T-shaped brackets inside the box + counterweight blocks on the side of the branch pipes to prevent tipping.

Available size

SIZE(1 x 3 x 2) | A | B | C | ||

INCH | DN | MM | MM | MM | MM |

3/4″ x 1/2″ x 3/4″ | 20 x 15 x 20 | 26.9 x 21.3 x 26.9 | 33 | 33 | 31 |

1‘’ x 1/4‘’ x1‘’ | 25 x 8 x 25 | 33.7 x 13.7 x 33.7 | 38 | 38 | 30 |

1″ x 1/2″ x 1″ | 25 x 15 x 25 | 33.7 x 21.3 x 33.7 | 38 | 38 | 34 |

1″ x 3/4″ x 1″ | 25 x 20 x 25 | 33.7 x 26.9 x 33.7 | 38 | 38 | 36 |

1-1/4″ x 1/2″ x 1-1/4″ | 32 x 15 x 32 | 42.4 x 21.3 x 42.4 | 45 | 45 | 38 |

1-1/4″ x 3/4″ x 1-1/4″ | 32 x 20 x 32 | 42.4 x 26.9 x 42.4 | 45 | 45 | 41 |

1-1/4″ x 1″ x 1-1/4″ | 32 x 25 x 32 | 42.4 x 33.7 x 42.4 | 45 | 45 | 42 |

1-1/2″ x 1/2″ x 1-1/2″ | 40 x 15 x 40 | 48.3 x 21.3 x 48.3 | 50 | 50 | 42 |

1-1/2″ x 3/4″ x 1-1/2″ | 40 x 20 x 40 | 48.3 x 26.9 x 48.3 | 50 | 50 | 44 |

1-1/2″ x 1″ x 1-1/2″ | 40 x 25 x 40 | 48.3 x 33.7 x 48.3 | 50 | 50 | 46 |

1-1/2″ x 1-1/4″ x 1-1/2″ | 40 x 32 x 40 | 48.3 x 42.4 x 48.3 | 50 | 50 | 48 |

2″ x 1/2″ x 2″ | 50 x 15 x 50 | 60.3 x 21.3 x 60.3 | 58 | 58 | 48 |

2″ x 3/4″ x 2″ | 50 x 20 x 50 | 60.3 x 26.9 x 60.3 | 58 | 58 | 50 |

2″ x 1″ x 2″ | 50 x 25 x 50 | 60.3 x 33.7 x 60.3 | 58 | 58 | 52 |

2″ x 1-1/4″ x 2″ | 50 x 32 x 50 | 60.3 x 42.4 x 60.3 | 58 | 58 | 54 |

2″ x 1-1/2″ x 2″ | 50 x 40 x 50 | 60.3 x 48.3 x 60.3 | 58 | 58 | 55 |

2-1/2″ x 1-1/2″ x 2-1/2″ | 65 x 40 x 65 | 76.1 x 48.3 x 76.1 | 68 | 68 | 64 |

2-1/2″ x 2″ x 2-1/2″ | 65 x 50 x 65 | 76.1 x 60.3 x 76.1 | 68 | 68 | 65 |

Note: : NSF 61 certificate is available for M1310 ~ M1337, except M1311.

- Chemical mixing system: Main pipes of equal diameter maintain main line pressure, while branch pipes of varying diameters precisely add auxiliary materials.

- HVAC engineering: Chilled water main pipes deliver at equal pressure, while branch pipes of varying diameters adapt to different terminal equipment.

- Fire protection network upgrade: UL/FM certification ensures stable pressure in main pipes and throttling and diversion in branch pipes for sprinkler systems.

- Industrial Equipment Layout: compressor main pipes maintain equal diameter output, while branch pipes vary in diameter to connect to pressure gauges.

- Ship Ballast System: main pipes in the engine room maintain equal diameter water supply, while branch pipes vary in diameter to control compartment flow.

- Agricultural irrigation hubs: Main pipes in pump stations maintain equal pressure, while branch pipes vary in diameter to match different irrigation zones.

- Energy sampling networks: Main pipes in oil and gas pipelines maintain equal diameter for detection, while branch pipes vary in diameter for sampling diversion.

- Municipal water supply nodes: Main roads maintain equal pressure, while branch pipes vary in diameter to adapt to different district requirements.

- Main pipe equal diameter design: Ensures stable fluid pressure/flow throughout the main line.

- Triple high-pressure sealing: Zero leakage at 25 bar operating conditions with BSPT tapered threads (main pipe x2 + branch pipe x1).

- Precise fluid control: Tapered branch pipes enable flow distribution according to demand.

- Corrosion-resistant matrix: Hot-dip galvanized coating resists industrial exhaust fumes and marine salt spray corrosion.

- Dual international certifications: UL/FM fire safety and NSF 61 certification (applies to models M1310–M1337, excluding M1311).

- Impact-resistant reinforcement: Ductile iron base absorbs water hammer impacts from branch pipe diameter changes.

- Wide temperature range reliability: Maintains triple interface seal integrity from -30°C to 120°C.

- Installation efficiency innovation: Single unit achieves main pipe pressure regulation + branch pipe flow control, reducing components by 50%.

- Equal-diameter port collaborative protection: dual main pipe injection-molded cover + branch pipe metal reducer sleeve.

- Asymmetric cushioning system: EPE pearl cotton molded and bonded to the main pipe’s equal-diameter flat surface + branch pipe reducer curved surface.

- Full-surface armor sealing: rust-proof oil impregnation + stretch film + bubble column triple protection.

- Precision positioning slots: laser-cut foam board fixed to the three-way interface according to dimensions.

- Flow direction identification system: Main pipe equal diameter arrow (→→) and branch pipe variable diameter symbol (▼) printed on the outer box.

- Load-bearing grading scheme: ≤1.5“ uses five-layer corrugated boxes/≥2” uses steel-band fumigated wooden boxes.

- Certification-specific labeling: NSF-certified models have independent labels (M1310~M1337, excluding M1311).

- Anti-Rolling Structure: T-shaped brackets inside the box + counterweight blocks on the side of the branch pipes to prevent tipping.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.