HOT PRODUCTS TAGS

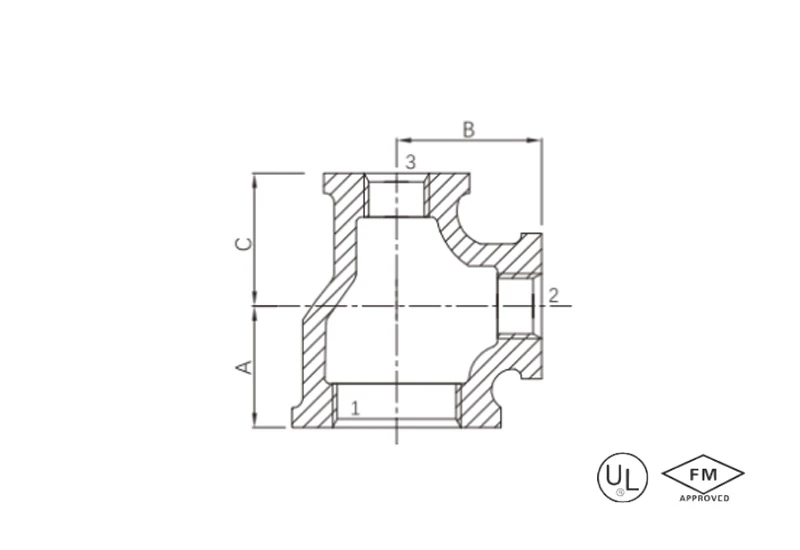

Malleable cast iron reducing tee (Unequal 3 ways)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1″ x 1/2″ x 3/4″—2″ x 1-1/2″ x 1-1/4″

description

Malleable cast iron unequal reducing tee, precise flow division, fits multiple pipe diameters, pressure-resistant and wear-resistant, flexible installation.

Specification

Available size

SIZE(1 x 3 x 2) | A | B | C | ||

INCH | DN | MM | MM | MM | MM |

1″ x 1/2″ x 3/4″ | 25 x 15 x 20 | 33.7 x 21.3 x 26.9 | 32 | 34 | 30 |

1″ x 3/4″ x 1/2″ | 25 x 20 x 15 | 33.7 x 26.9 x 21.3 | 35 | 36 | 31 |

1-1/4″ x 1/2″ x 3/4″ | 32 x 15 x 20 | 42.4 x 21.3 x 26.9 | 30 | 36 | 31 |

1-1/4″ x 3/4″ x 1/2″ | 32 x 20 x 15 | 42.4 x 26.9 x 21.3 | 35 | 38 | 29 |

1-1/4″ x 1/2″ x 1″ | 32 x 15 x 25 | 42.4 x 21.3 x 33.7 | 34 | 38 | 32 |

1-1/4″ x 1″ x 1/2″ | 32 x 25 x 15 | 42.4 x 33.7 x 21.3 | 39 | 42 | 34 |

1-1/4″ x 3/4″ x 1″ | 32 x 20 x 25 | 42.4 x 26.9 x 33.7 | 36 | 41 | 35 |

1-1/4″ x 1″ x 3/4″ | 32 x 25 x 20 | 42.4 x 33.7 x 26.9 | 40 | 42 | 36 |

1-1/2″x 1/2″ x 1″ | 40 x 15 x 25 | 48.3 x 21.3 x 33.7 | 44 | 46 | 34 |

1-1/2″ x 1-1/4″ x 3/4″ | 40 x 32 x 20 | 48.3 x 42.4 x 26.9 | 46 | 48 | 41 |

1-1/2″ x 3/4″ x 1-1/4″ | 40 x 20 x 32 | 48.3 x 36.9 x 42.4 | 38 | 44 | 36 |

1-1/2″ x 1-1/4″ x 1″ | 40 x 32 x 25 | 48.3 x 42.4 x 33.7 | 42 | 46 | 40 |

2″ x 1-1/2″ x 1″ | 50 x 40 x 25 | 60.3 x 48.3 x 33.7 | 51 | 55 | 46 |

2″ x 1″ x 1-1/2″ | 50 x 25 x 40 | 60.3 x 33.7 x 48.3 | 44 | 52 | 42 |

2″ x 1-1/4″ x 1-1/2″ | 50 x 32 x 40 | 60.3 x 42.4 x 48.3 | 48 | 54 | 46 |

2″ x 1-1/2″ x 1-1/4″ | 50 x 40 x 32 | 60.3 x 48.3 x 42.4 | 52 | 55 | 48 |

application

- Chemical Formulation System: Three-way reducers enable differentiated ratio delivery of multiple media.

- HVAC Engineering: Multi-stage reducers on the chilled water main pipe accommodate different terminal equipment groups.

- Fire Protection Pipeline Renovation: UL/FM certification ensures mixed connections of pipes of various specifications in sprinkler systems.

- Industrial Reaction Equipment: Multi-stage reducers at the inlet and outlet of reactors control pressure gradients.

- Ship Integrated Piping: Integration of fuel oil, fresh water, and compressed air piping of different diameters within the engine room space.

- Agricultural Irrigation Matrix: Multi-stage diameter adjustment of the main pipeline at the pump station to match tiered irrigation areas.

- Energy Hybrid Hub: Synchronized sampling and diversion through multiple specification inspection ports on oil and gas pipelines.

- Municipal Pipeline Network Upgrade: Multi-branch pipeline of different diameters to adapt to the connection of new and old pipeline networks on main roads.

advantages

- Three-dimensional variable diameter design: Simultaneously achieves independent variable diameter adjustment of the main pipe and dual branch pipes in a single piece.

- Triple high-pressure sealing: 25 bar operating conditions with BSPT tapered thread triple-directional zero-leakage sealing.

- Precise fluid ratio: Asymmetric flow channels optimize mixing efficiency for media of different pipe diameters.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists corrosion from industrial composite media and marine environments.

- Pressure-resistant matrix reinforcement: Ductile iron matrix disperses stress peaks across three directions.

- Wide temperature range stability: Maintains triple variable-diameter interface integrity from -30°C to 120°C.

- Space-saving innovation: Saves 60% installation space compared to traditional components.

- Installation efficiency leap: Single-piece replacement for multiple component connections reduces leakage points by 70%.

packing

- Different diameter port protection: Customized three-size injection-molded caps nested with threaded ports.

- Three-dimensional cushioning system: EPE pearl cotton molded and bonded to three-dimensional variable diameter curved surfaces.

- Full surface armor sealing: Vapor phase anti-rust film + anti-static bubble columns in three-dimensional wrapping.

- Precise anti-error positioning: Laser-cut foam boards fixed in three-dimensional positions according to size.

- Flow direction identification matrix: Outer box printed with three-directional fluid arrows + variable diameter symbols (▼/▲).

- Load-bearing reinforcement solution: Full-size steel-belt reinforced fumigated wooden box (load-bearing capacity ≥ 2 tons).

- Smart traceability management: Box body laser anti-counterfeiting code linked to three-dimensional dimensional data.

- Anti-rolling structure: Pyramid-shaped internal supports lock three-way connectors in zero displacement.

Available size

SIZE(1 x 3 x 2) | A | B | C | ||

INCH | DN | MM | MM | MM | MM |

1″ x 1/2″ x 3/4″ | 25 x 15 x 20 | 33.7 x 21.3 x 26.9 | 32 | 34 | 30 |

1″ x 3/4″ x 1/2″ | 25 x 20 x 15 | 33.7 x 26.9 x 21.3 | 35 | 36 | 31 |

1-1/4″ x 1/2″ x 3/4″ | 32 x 15 x 20 | 42.4 x 21.3 x 26.9 | 30 | 36 | 31 |

1-1/4″ x 3/4″ x 1/2″ | 32 x 20 x 15 | 42.4 x 26.9 x 21.3 | 35 | 38 | 29 |

1-1/4″ x 1/2″ x 1″ | 32 x 15 x 25 | 42.4 x 21.3 x 33.7 | 34 | 38 | 32 |

1-1/4″ x 1″ x 1/2″ | 32 x 25 x 15 | 42.4 x 33.7 x 21.3 | 39 | 42 | 34 |

1-1/4″ x 3/4″ x 1″ | 32 x 20 x 25 | 42.4 x 26.9 x 33.7 | 36 | 41 | 35 |

1-1/4″ x 1″ x 3/4″ | 32 x 25 x 20 | 42.4 x 33.7 x 26.9 | 40 | 42 | 36 |

1-1/2″x 1/2″ x 1″ | 40 x 15 x 25 | 48.3 x 21.3 x 33.7 | 44 | 46 | 34 |

1-1/2″ x 1-1/4″ x 3/4″ | 40 x 32 x 20 | 48.3 x 42.4 x 26.9 | 46 | 48 | 41 |

1-1/2″ x 3/4″ x 1-1/4″ | 40 x 20 x 32 | 48.3 x 36.9 x 42.4 | 38 | 44 | 36 |

1-1/2″ x 1-1/4″ x 1″ | 40 x 32 x 25 | 48.3 x 42.4 x 33.7 | 42 | 46 | 40 |

2″ x 1-1/2″ x 1″ | 50 x 40 x 25 | 60.3 x 48.3 x 33.7 | 51 | 55 | 46 |

2″ x 1″ x 1-1/2″ | 50 x 25 x 40 | 60.3 x 33.7 x 48.3 | 44 | 52 | 42 |

2″ x 1-1/4″ x 1-1/2″ | 50 x 32 x 40 | 60.3 x 42.4 x 48.3 | 48 | 54 | 46 |

2″ x 1-1/2″ x 1-1/4″ | 50 x 40 x 32 | 60.3 x 48.3 x 42.4 | 52 | 55 | 48 |

- Chemical Formulation System: Three-way reducers enable differentiated ratio delivery of multiple media.

- HVAC Engineering: Multi-stage reducers on the chilled water main pipe accommodate different terminal equipment groups.

- Fire Protection Pipeline Renovation: UL/FM certification ensures mixed connections of pipes of various specifications in sprinkler systems.

- Industrial Reaction Equipment: Multi-stage reducers at the inlet and outlet of reactors control pressure gradients.

- Ship Integrated Piping: Integration of fuel oil, fresh water, and compressed air piping of different diameters within the engine room space.

- Agricultural Irrigation Matrix: Multi-stage diameter adjustment of the main pipeline at the pump station to match tiered irrigation areas.

- Energy Hybrid Hub: Synchronized sampling and diversion through multiple specification inspection ports on oil and gas pipelines.

- Municipal Pipeline Network Upgrade: Multi-branch pipeline of different diameters to adapt to the connection of new and old pipeline networks on main roads.

- Three-dimensional variable diameter design: Simultaneously achieves independent variable diameter adjustment of the main pipe and dual branch pipes in a single piece.

- Triple high-pressure sealing: 25 bar operating conditions with BSPT tapered thread triple-directional zero-leakage sealing.

- Precise fluid ratio: Asymmetric flow channels optimize mixing efficiency for media of different pipe diameters.

- Full environmental corrosion resistance: Hot-dip galvanized coating resists corrosion from industrial composite media and marine environments.

- Pressure-resistant matrix reinforcement: Ductile iron matrix disperses stress peaks across three directions.

- Wide temperature range stability: Maintains triple variable-diameter interface integrity from -30°C to 120°C.

- Space-saving innovation: Saves 60% installation space compared to traditional components.

- Installation efficiency leap: Single-piece replacement for multiple component connections reduces leakage points by 70%.

- Different diameter port protection: Customized three-size injection-molded caps nested with threaded ports.

- Three-dimensional cushioning system: EPE pearl cotton molded and bonded to three-dimensional variable diameter curved surfaces.

- Full surface armor sealing: Vapor phase anti-rust film + anti-static bubble columns in three-dimensional wrapping.

- Precise anti-error positioning: Laser-cut foam boards fixed in three-dimensional positions according to size.

- Flow direction identification matrix: Outer box printed with three-directional fluid arrows + variable diameter symbols (▼/▲).

- Load-bearing reinforcement solution: Full-size steel-belt reinforced fumigated wooden box (load-bearing capacity ≥ 2 tons).

- Smart traceability management: Box body laser anti-counterfeiting code linked to three-dimensional dimensional data.

- Anti-rolling structure: Pyramid-shaped internal supports lock three-way connectors in zero displacement.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.