HOT PRODUCTS TAGS

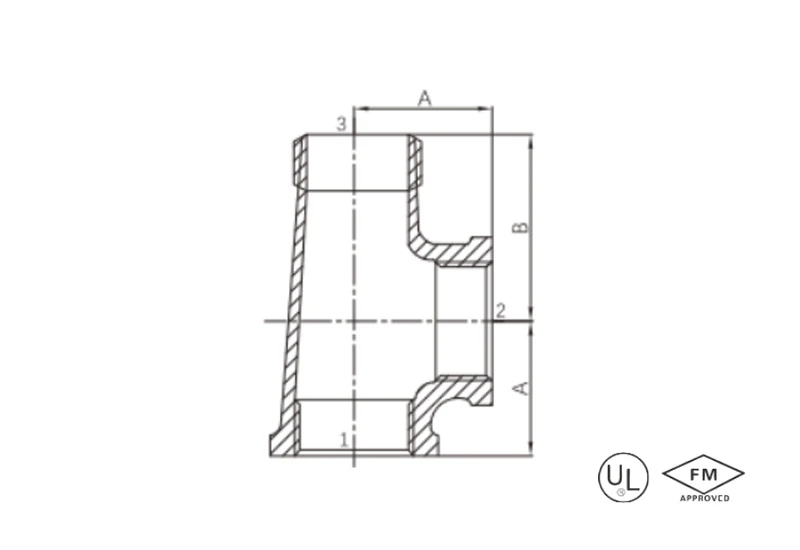

Malleable cast iron service tee

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″—2″

description

Malleable cast iron unequal reducing tee, precise flow division, fits multiple pipe diameters, pressure-resistant and wear-resistant, flexible installation.

Specification

Available size

| SIZE(1 x 3 x 2) | A | B | ||

| INCH | DN | MM | MM | MM |

| 1/2″ | 15 | 21.3 | 28.5 | 41.5 |

| 3/4″ | 20 | 26.9 | 33.5 | 48 |

| 1″ | 25 | 33.7 | 38 | 54.5 |

| 1-1/4″ | 32 | 42.4 | 44.5 | 62 |

| 1-1/2″ | 40 | 48.3 | 49.5 | 68.5 |

| 2″ | 50 | 60.3 | 57 | 83 |

application

- Terminal seal guarantee: tapered thread structure realizes permanent closure of the pipe end

- High-pressure protection performance: Meets the pressure requirements of industrial piping system terminals

- Long-lasting anti-corrosion design: The hot-dip galvanized layer provides comprehensive corrosion protection

- Structural Integrity: Malleable iron matrix ensures impact strength at the end

- Easy to install: Standard wrenches can be quickly installed and removed

- Full specification adaptation: covering microtubes to industrial main terminals.

advantages

- Three-dimensional reducer integration: a single piece realizes independent reduction adjustment of the main pipe and two branches

- Precise fluid control: Asymmetric runners optimize multi-pipe diameter media mixing efficiency

- Enhanced anti-corrosion: hot-dip galvanized layer resists industrial media and salt spray environmental erosion

- Stress dispersion strengthening: malleable iron matrix equilibrium channels three-way pressure peaks

- Compact space design: Asymmetrical structure saves up to 60% of installation space compared to traditional components

- Assembly efficiency jumps: Single-piece replaces multi-component connections, reducing the risk of leakage by 70%.

packing

- Reduced port graded protection: stepped injection molded cover nested with three-gauge threaded ports

- Three-dimensional surface cushioning: EPE pearl cotton molded to fit the curved surface of the reducer structure

- Fully sealed protective layer: vapor phase anti-rust film and anti-static bubble column three-dimensional wrapping

- Error-proof positioning system: Laser-cut foam board is fixed according to the size of the three-dimensional card position

- Flow direction indication management: outer carton printing three-way fluid arrow and diameter reduction symbol (▼/▲)

- Load-bearing reinforcement scheme: steel belt reinforced fumigation wooden box suitable for full-size transportation

- Traceability data management: The laser anti-counterfeiting code of the box is associated with the three-dimensional parameters of the product.

Available size

| SIZE(1 x 3 x 2) | A | B | ||

| INCH | DN | MM | MM | MM |

| 1/2″ | 15 | 21.3 | 28.5 | 41.5 |

| 3/4″ | 20 | 26.9 | 33.5 | 48 |

| 1″ | 25 | 33.7 | 38 | 54.5 |

| 1-1/4″ | 32 | 42.4 | 44.5 | 62 |

| 1-1/2″ | 40 | 48.3 | 49.5 | 68.5 |

| 2″ | 50 | 60.3 | 57 | 83 |

- Terminal seal guarantee: tapered thread structure realizes permanent closure of the pipe end

- High-pressure protection performance: Meets the pressure requirements of industrial piping system terminals

- Long-lasting anti-corrosion design: The hot-dip galvanized layer provides comprehensive corrosion protection

- Structural Integrity: Malleable iron matrix ensures impact strength at the end

- Easy to install: Standard wrenches can be quickly installed and removed

- Full specification adaptation: covering microtubes to industrial main terminals.

- Three-dimensional reducer integration: a single piece realizes independent reduction adjustment of the main pipe and two branches

- Precise fluid control: Asymmetric runners optimize multi-pipe diameter media mixing efficiency

- Enhanced anti-corrosion: hot-dip galvanized layer resists industrial media and salt spray environmental erosion

- Stress dispersion strengthening: malleable iron matrix equilibrium channels three-way pressure peaks

- Compact space design: Asymmetrical structure saves up to 60% of installation space compared to traditional components

- Assembly efficiency jumps: Single-piece replaces multi-component connections, reducing the risk of leakage by 70%.

- Reduced port graded protection: stepped injection molded cover nested with three-gauge threaded ports

- Three-dimensional surface cushioning: EPE pearl cotton molded to fit the curved surface of the reducer structure

- Fully sealed protective layer: vapor phase anti-rust film and anti-static bubble column three-dimensional wrapping

- Error-proof positioning system: Laser-cut foam board is fixed according to the size of the three-dimensional card position

- Flow direction indication management: outer carton printing three-way fluid arrow and diameter reduction symbol (▼/▲)

- Load-bearing reinforcement scheme: steel belt reinforced fumigation wooden box suitable for full-size transportation

- Traceability data management: The laser anti-counterfeiting code of the box is associated with the three-dimensional parameters of the product.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.