HOT PRODUCTS TAGS

Malleable cast iron unequal cross (Reducing cross)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 3/4″ x 1/2″—4″ x 3″

description

Malleable cast iron unequal cross, precise diameter-changing flow division, multi-diameter adaptation, tough and durable, optimizing pipeline layout.

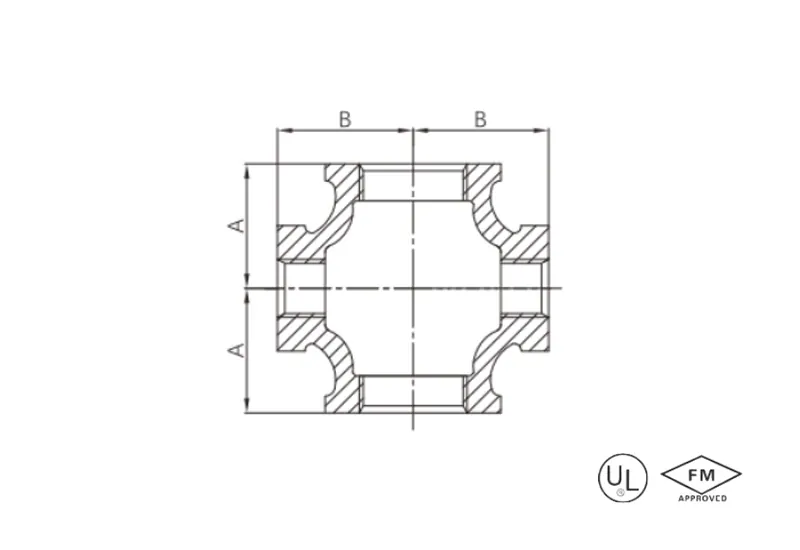

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 30 | 31 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 32 | 34 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 35 | 36 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 34 | 38 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 36 | 41 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 40 | 42 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 36 | 42 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 38 | 44 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 42 | 46 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 46 | 48 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 40 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 44 | 52 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 48 | 54 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 52 | 55 |

2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 43 | 57 |

2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 47 | 60 |

2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 52 | 62 |

2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 55 | 63 |

2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 61 | 66 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 51 | 67 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 55 | 70 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 58 | 71 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 72 | 76 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 72 | 76 |

4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 56 | 81 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 60 | 84 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 61 | 84 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 70 | 86 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 84 | 92 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 82 | 90 |

Note: NSF 61 certificate is available for M2010 ~ M2053.

application

- Industrial Pipeline Hub: Four-way eccentric design enables differentiated flow control of multiple branches from the main pipeline.

- Chemical Reaction Matrix: Multiple specifications of synchronous eccentric control at the inlet and outlet of the reactor vessel regulate pressure gradients.

- Ship Integrated Piping: Multi-level eccentric integration of fuel oil, cooling water, and compressed air within the engine room space.

- Fire Protection System Expansion: UL-certified high-flow sprinkler pipeline network with mixed connections of multiple pipe specifications.

- Agricultural Irrigation Matrix: Pump station main pipeline with stepped diameter matching for sector-shaped irrigation blocks.

- Municipal Water Supply Upgrade: Main pipeline with four-way different diameters for pressure balancing and mixed connection of new and old pipelines.

- Energy Monitoring Hub: Oil and gas pipelines with synchronized sampling and diversion through multiple-specification detection ports.

- Mining Conveyance Network: High wear resistance characteristics for slurry pipeline with multiple branches and different diameters for diversion.

advantages

- Four-way variable diameter precision control: Single piece achieves precise adaptation of four-way independent pipe diameters.

- High-pressure sealing matrix: 25 bar working conditions with four-way BSPT tapered threads ensure zero leakage.

- NSF safety certification: Drinking water-grade galvanized coating eliminates the risk of heavy metal precipitation.

- Intelligent fluid distribution: Asymmetric flow channels optimize the mixing efficiency of multiple pipe diameters.

- Stress Distribution Reinforcement: Ductile iron base disperses pressure peaks across four directions.

- All-Environment Corrosion Resistance: Hot-dip galvanized coating resists industrial acid/alkali and marine salt fog corrosion.

- Installation Efficiency Revolution: Single component replaces three-way + variable diameter pipe assembly, reducing leakage points by 80%.

- Wide Temperature Range Reliability: Maintains structural integrity of four-way variable diameter interfaces from -30°C to 120°C.

packing

- Stepped port protection: Four-size injection-molded caps nested with different diameter threaded ports.

- Four-dimensional curved surface cushioning: EPE pearl cotton molded and bonded to curved surfaces of variable-diameter flow channels.

- Anti-corrosion armor system: Vapor-phase anti-corrosion film + moisture-proof paper composite vacuum wrapping.

- Precision error-proofing structure: Laser-cut pine wood lattice brackets fitted to size.

- Heavy-duty load-bearing solution: Steel-reinforced fumigated wooden boxes (suitable for DN100 load-bearing capacity).

- Holographic traceability management: Box body laser codes linked to NSF certification + variable-diameter parameters.

- Zero-displacement protection: Lattice steel frame inner box locking for stable four-way transportation.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

3/4″ x 1/2″ | 20 x 15 | 26.9 x 21.3 | 30 | 31 |

1″ x 1/2″ | 25 x 15 | 33.7 x 21.3 | 32 | 34 |

1″ x 3/4″ | 25 x 20 | 33.7 x 26.9 | 35 | 36 |

1-1/4″ x 1/2″ | 32 x 15 | 42.4 x 21.3 | 34 | 38 |

1-1/4″ x 3/4″ | 32 x 20 | 42.4 x 26.9 | 36 | 41 |

1-1/4″ x 1″ | 32 x 25 | 42.4 x 33.7 | 40 | 42 |

1-1/2″ x 1/2″ | 40 x 15 | 48.3 x 21.3 | 36 | 42 |

1-1/2″ x 3/4″ | 40 x 20 | 48.3 x 26.9 | 38 | 44 |

1-1/2″ x 1″ | 40 x 25 | 48.3 x 33.7 | 42 | 46 |

1-1/2″ x 1-1/4″ | 40 x 32 | 48.3 x 42.4 | 46 | 48 |

2″ x 3/4″ | 50 x 20 | 60.3 x 26.9 | 40 | 50 |

2″ x 1″ | 50 x 25 | 60.3 x 33.7 | 44 | 52 |

2″ x 1-1/4″ | 50 x 32 | 60.3 x 42.4 | 48 | 54 |

2″ x 1-1/2″ | 50 x 40 | 60.3 x 48.3 | 52 | 55 |

2-1/2″ x 3/4″ | 65 x 20 | 76.1 x 26.9 | 43 | 57 |

2-1/2″ x 1″ | 65 x 25 | 76.1 x 33.7 | 47 | 60 |

2-1/2″ x 1-1/4″ | 65 x 32 | 76.1 x 42.4 | 52 | 62 |

2-1/2″ x 1-1/2″ | 65 x 40 | 76.1 x 48.3 | 55 | 63 |

2-1/2″ x 2″ | 65 x 50 | 76.1 x 60.3 | 61 | 66 |

3″ x 3/4″ | 80 x 20 | 88.9 x 26.9 | 45 | 65 |

3″ x 1″ | 80 x 25 | 88.9 x 33.7 | 51 | 67 |

3″ x 1-1/4″ | 80 x 32 | 88.9 x 42.4 | 55 | 70 |

3″ x 1-1/2″ | 80 x 40 | 88.9 x 48.3 | 58 | 71 |

3″ x 2″ | 80 x 50 | 88.9 x 60.3 | 64 | 73 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 72 | 76 |

3″ x 2-1/2″ | 80 x 65 | 88.9 x 76.1 | 72 | 76 |

4″ x 1″ | 100 x 25 | 114.3 x 33.7 | 56 | 81 |

4″ x 1-1/4″ | 100 x 32 | 114.3 x 42.4 | 60 | 84 |

4″ x 1-1/2″ | 100 x 40 | 114.3 x 48.3 | 61 | 84 |

4″ x 2″ | 100 x 50 | 114.3 x 60.3 | 70 | 86 |

4″ x 2-1/2″ | 100 x 65 | 114.3 x 76.1 | 84 | 92 |

4″ x 3″ | 100 x 80 | 114.3 x 88.9 | 82 | 90 |

Note: NSF 61 certificate is available for M2010 ~ M2053.

- Industrial Pipeline Hub: Four-way eccentric design enables differentiated flow control of multiple branches from the main pipeline.

- Chemical Reaction Matrix: Multiple specifications of synchronous eccentric control at the inlet and outlet of the reactor vessel regulate pressure gradients.

- Ship Integrated Piping: Multi-level eccentric integration of fuel oil, cooling water, and compressed air within the engine room space.

- Fire Protection System Expansion: UL-certified high-flow sprinkler pipeline network with mixed connections of multiple pipe specifications.

- Agricultural Irrigation Matrix: Pump station main pipeline with stepped diameter matching for sector-shaped irrigation blocks.

- Municipal Water Supply Upgrade: Main pipeline with four-way different diameters for pressure balancing and mixed connection of new and old pipelines.

- Energy Monitoring Hub: Oil and gas pipelines with synchronized sampling and diversion through multiple-specification detection ports.

- Mining Conveyance Network: High wear resistance characteristics for slurry pipeline with multiple branches and different diameters for diversion.

- Four-way variable diameter precision control: Single piece achieves precise adaptation of four-way independent pipe diameters.

- High-pressure sealing matrix: 25 bar working conditions with four-way BSPT tapered threads ensure zero leakage.

- NSF safety certification: Drinking water-grade galvanized coating eliminates the risk of heavy metal precipitation.

- Intelligent fluid distribution: Asymmetric flow channels optimize the mixing efficiency of multiple pipe diameters.

- Stress Distribution Reinforcement: Ductile iron base disperses pressure peaks across four directions.

- All-Environment Corrosion Resistance: Hot-dip galvanized coating resists industrial acid/alkali and marine salt fog corrosion.

- Installation Efficiency Revolution: Single component replaces three-way + variable diameter pipe assembly, reducing leakage points by 80%.

- Wide Temperature Range Reliability: Maintains structural integrity of four-way variable diameter interfaces from -30°C to 120°C.

- Stepped port protection: Four-size injection-molded caps nested with different diameter threaded ports.

- Four-dimensional curved surface cushioning: EPE pearl cotton molded and bonded to curved surfaces of variable-diameter flow channels.

- Anti-corrosion armor system: Vapor-phase anti-corrosion film + moisture-proof paper composite vacuum wrapping.

- Precision error-proofing structure: Laser-cut pine wood lattice brackets fitted to size.

- Heavy-duty load-bearing solution: Steel-reinforced fumigated wooden boxes (suitable for DN100 load-bearing capacity).

- Holographic traceability management: Box body laser codes linked to NSF certification + variable-diameter parameters.

- Zero-displacement protection: Lattice steel frame inner box locking for stable four-way transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.