HOT PRODUCTS TAGS

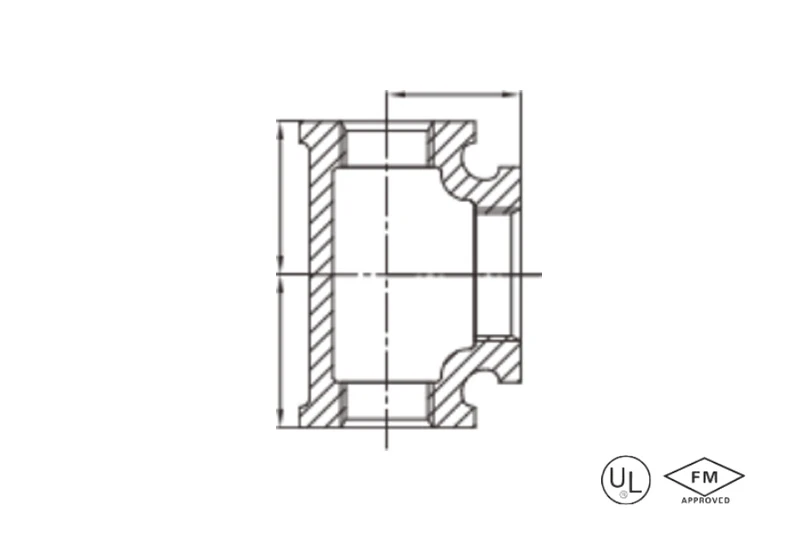

Malleable cast iron unequal tee (Increasing tee)

·Standard: ISO 49 / EN 10242

UL/FM

·Material: BS EN 1562, EN-GJMB-350-10

·Thread: BSPT

·W. pressure: 20 ~ 25 bar, ≤ PN25

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ x 1/2″ x 3/4″-2-1/2″ x 2-1/2″ x 4″

description

The malleable cast iron unequal tee (increasing tee) features reliable quality and flexible connection, facilitating smooth diameter – increasing transportation in piping systems.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ x 1/2″ x 3/4″ | 15 x 15 x 20 | 21.3 x 21.3 x 26.9 | 31 | 30 |

1/2″ x 1/2″ x 1″ | 15 x 15 x 25 | 21.3 x 21.3 x 33.7 | 34 | 32 |

3/4″ x 3/4″ x 1″ | 20 x 20 x 25 | 26.9 x 26.9 x 33.7 | 36 | 35 |

3/4″ x 3/4″ x 1-1/4″ | 20 x 20 x 32 | 26.9 x 26.9 x 42.4 | 41 | 36 |

1″ x 1″ x 1-1/4″ | 25 x 25 x 32 | 33.7 x 33.7 x 42.4 | 42 | 40 |

1″ x 1″ x 1-1/2″ | 25 x 25 x 40 | 33.7 x 33.7 x 48.3 | 46 | 42 |

1″ x 1″ x 2″ | 25 x 25 x 50 | 33.7 x 33.7 x 60.3 | 52 | 44 |

1″ x 1″ x 2-1/2″ | 25 x 25 x 65 | 33.7 x 33.7 x 76.1 | 60 | 47 |

1-1/4″ x 1-1/4″ x 1-1/2″ | 32 x 32 x 40 | 42.4 x 42.4 x 48.3 | 48 | 46 |

1-1/4″ x 1-1/4″ x 2″ | 32 x 32 x 50 | 42.4 x 42.4 x 60.3 | 54 | 48 |

1-1/2″ x 1-1/2″ x 2″ | 40 x 40 x 50 | 48.3 x 48.3 x 60.3 | 55 | 52 |

1-1/2″ x 1-1/2″ x 2-1/2″ | 40 x 40 x 65 | 48.3 x 48.3 x 76.1 | 63 | 55 |

2″ x 2″ x 2-1/2″ | 50 x 50 x 65 | 60.3 x 60.3 x 76.1 | 66 | 61 |

2″ x 2″ x 3″ | 50 x 50 x 80 | 60.3 x 60.3 x 88.9 | 73 | 64 |

2-1/2″ x 2-1/2″ x 3″ | 65 x 65 x 80 | 76.1 x 76.1 x 88.9 | 76 | 72 |

2-1/2″ x 2-1/2″ x 4″ | 65 x 65 x 100 | 76.1 x 76.1 x 114.3 | 92 | 84 |

Note: NSF 61 certificate is available for M1110 ~ M1152.

application

- Pump Station Expansion Project: Main pipeline with equal diameter input, branch pipeline expansion to achieve flow upgrade.

- HVAC System Renovation: Expansion of branches of the chilled water main pipeline to connect to large terminal equipment.

- Fire Protection Network Upgrade: UL/FM certification ensures pressure expansion of sprinkler system branch pipelines.

- Industrial Fluid Network: Stepwise increase in flow rate of chemical pipeline branches for transportation.

- Ship Power System: Expansion of main fuel/coolant pipeline branches in the engine room.

- Agricultural Irrigation Hub: Main pipeline with equal pressure input, branch pipeline expansion for irrigation upgrades.

- Energy Transmission Network: Branch pipeline expansion and diversion at oil and gas pipeline inspection ports.

- Municipal Pipeline Network Node: Main water supply pipeline with equal pressure input, branch pipeline expansion for maintenance access.

advantages

- Stepped expansion design: Main pipe maintains constant diameter for pressure stabilization, while branch pipes seamlessly increase flow rate by 30%.

- Triple high-pressure sealing: 25 bar operating conditions with BSPT tapered threads for zero leakage sealing (main pipe x2 + branch pipe x1).

- Corrosion-resistant matrix: Hot-dip galvanized coating resists corrosion from acidic/alkaline media and marine environments.

- Fluid-optimized structure: Tapered transition in branch pipes reduces vortex resistance by 25%.

- Dual international certifications: UL/FM fire safety and NSF 61 certification (covering models M1110 to M1152).

- Water hammer resistance enhancement: Ductile iron base absorbs pressure fluctuation impact peaks.

- Wide temperature range compatibility: Maintains structural seal integrity from -30°C to 120°C.

- Lifetime maintenance-free commitment: Special annealing process extends the service life of the piping system.

packing

- Differential-diameter port protection: Main pipe injection-molded cover + branch pipe metal flared sleeve.

- Three-dimensional cushioning system: EPE pearl cotton molded stepped wrapping around the three-way fitting body.

- Full-surface armor treatment: Vapor-phase anti-rust film + anti-static bubble columns with triple sealing.

- Anti-misalignment positioning: Laser-cut foam boards with precisely sized stepped slots.

- Flow direction identification system: Main pipe equal diameter arrow printed on outer box + branch pipe expansion symbol (▲).

- Load-bearing grading scheme: ≤2“ uses five-layer corrugated box / ≥2.5” uses steel-band fumigated wooden box.

- Certification special management: NSF certification scope independently labeled (M1110~M1152).

- Anti-Rolling Structure: Asymmetric brackets inside the box secure three-way fittings for zero-displacement transportation.

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ x 1/2″ x 3/4″ | 15 x 15 x 20 | 21.3 x 21.3 x 26.9 | 31 | 30 |

1/2″ x 1/2″ x 1″ | 15 x 15 x 25 | 21.3 x 21.3 x 33.7 | 34 | 32 |

3/4″ x 3/4″ x 1″ | 20 x 20 x 25 | 26.9 x 26.9 x 33.7 | 36 | 35 |

3/4″ x 3/4″ x 1-1/4″ | 20 x 20 x 32 | 26.9 x 26.9 x 42.4 | 41 | 36 |

1″ x 1″ x 1-1/4″ | 25 x 25 x 32 | 33.7 x 33.7 x 42.4 | 42 | 40 |

1″ x 1″ x 1-1/2″ | 25 x 25 x 40 | 33.7 x 33.7 x 48.3 | 46 | 42 |

1″ x 1″ x 2″ | 25 x 25 x 50 | 33.7 x 33.7 x 60.3 | 52 | 44 |

1″ x 1″ x 2-1/2″ | 25 x 25 x 65 | 33.7 x 33.7 x 76.1 | 60 | 47 |

1-1/4″ x 1-1/4″ x 1-1/2″ | 32 x 32 x 40 | 42.4 x 42.4 x 48.3 | 48 | 46 |

1-1/4″ x 1-1/4″ x 2″ | 32 x 32 x 50 | 42.4 x 42.4 x 60.3 | 54 | 48 |

1-1/2″ x 1-1/2″ x 2″ | 40 x 40 x 50 | 48.3 x 48.3 x 60.3 | 55 | 52 |

1-1/2″ x 1-1/2″ x 2-1/2″ | 40 x 40 x 65 | 48.3 x 48.3 x 76.1 | 63 | 55 |

2″ x 2″ x 2-1/2″ | 50 x 50 x 65 | 60.3 x 60.3 x 76.1 | 66 | 61 |

2″ x 2″ x 3″ | 50 x 50 x 80 | 60.3 x 60.3 x 88.9 | 73 | 64 |

2-1/2″ x 2-1/2″ x 3″ | 65 x 65 x 80 | 76.1 x 76.1 x 88.9 | 76 | 72 |

2-1/2″ x 2-1/2″ x 4″ | 65 x 65 x 100 | 76.1 x 76.1 x 114.3 | 92 | 84 |

Note: NSF 61 certificate is available for M1110 ~ M1152.

- Pump Station Expansion Project: Main pipeline with equal diameter input, branch pipeline expansion to achieve flow upgrade.

- HVAC System Renovation: Expansion of branches of the chilled water main pipeline to connect to large terminal equipment.

- Fire Protection Network Upgrade: UL/FM certification ensures pressure expansion of sprinkler system branch pipelines.

- Industrial Fluid Network: Stepwise increase in flow rate of chemical pipeline branches for transportation.

- Ship Power System: Expansion of main fuel/coolant pipeline branches in the engine room.

- Agricultural Irrigation Hub: Main pipeline with equal pressure input, branch pipeline expansion for irrigation upgrades.

- Energy Transmission Network: Branch pipeline expansion and diversion at oil and gas pipeline inspection ports.

- Municipal Pipeline Network Node: Main water supply pipeline with equal pressure input, branch pipeline expansion for maintenance access.

- Stepped expansion design: Main pipe maintains constant diameter for pressure stabilization, while branch pipes seamlessly increase flow rate by 30%.

- Triple high-pressure sealing: 25 bar operating conditions with BSPT tapered threads for zero leakage sealing (main pipe x2 + branch pipe x1).

- Corrosion-resistant matrix: Hot-dip galvanized coating resists corrosion from acidic/alkaline media and marine environments.

- Fluid-optimized structure: Tapered transition in branch pipes reduces vortex resistance by 25%.

- Dual international certifications: UL/FM fire safety and NSF 61 certification (covering models M1110 to M1152).

- Water hammer resistance enhancement: Ductile iron base absorbs pressure fluctuation impact peaks.

- Wide temperature range compatibility: Maintains structural seal integrity from -30°C to 120°C.

- Lifetime maintenance-free commitment: Special annealing process extends the service life of the piping system.

- Differential-diameter port protection: Main pipe injection-molded cover + branch pipe metal flared sleeve.

- Three-dimensional cushioning system: EPE pearl cotton molded stepped wrapping around the three-way fitting body.

- Full-surface armor treatment: Vapor-phase anti-rust film + anti-static bubble columns with triple sealing.

- Anti-misalignment positioning: Laser-cut foam boards with precisely sized stepped slots.

- Flow direction identification system: Main pipe equal diameter arrow printed on outer box + branch pipe expansion symbol (▲).

- Load-bearing grading scheme: ≤2“ uses five-layer corrugated box / ≥2.5” uses steel-band fumigated wooden box.

- Certification special management: NSF certification scope independently labeled (M1110~M1152).

- Anti-Rolling Structure: Asymmetric brackets inside the box secure three-way fittings for zero-displacement transportation.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.