HOT PRODUCTS TAGS

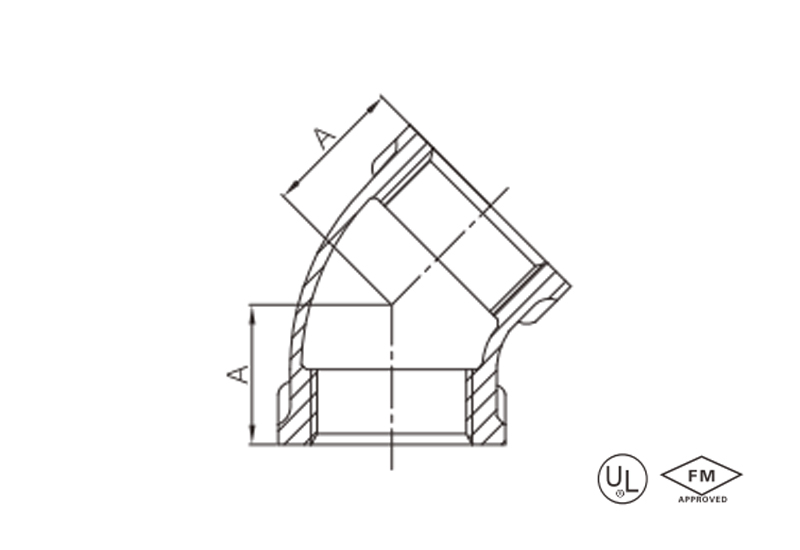

Malleable iron 45° straight elbow

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —6″ (Class 150)

1/4″—4″ (Class 300)

description

Malleable iron 45° straight elbow, with precise angle, strong impact resistance, easy installation and flexible adaptation.

Specification

Available size

| SIZE | A | ||

| INCH | DN | MM | MM |

| 1/2″ | 15 | 21.3 | 22.4 |

| 3/4″ | 20 | 26.7 | 24.9 |

| 1″ | 25 | 33.4 | 28.5 |

| 1-1/4″ | 32 | 42.4 | 32.8 |

| 1-1/2″ | 40 | 48.3 | 36.3 |

| 2″ | 50 | 60.3 | 42.7 |

| 2-1/2″ | 65 | 73 | 49.5 |

| 3″ | 80 | 88.9 | 55.1 |

| 4″ | 100 | 114.3 | 66.3 |

| 6″ | 150 | 168.3 | 87.9 |

| 1/4” | 8 | 13.7 | 20.6 |

| 3/8” | 10 | 17.1 | 22.4 |

| 1/2” | 15 | 21.3 | 25.4 |

| 3/4” | 20 | 26.7 | 28.7 |

| 1” | 25 | 33.4 | 33.3 |

| 1-1/4” | 32 | 42.2 | 38.1 |

| 1-1/2” | 40 | 48.3 | 42.9 |

| 2” | 50 | 60.3 | 50.8 |

| 2-1/2” | 65 | 73 | 57.2 |

| 3” | 80 | 88.9 | 63.5 |

| 4” | 100 | 114.3 | 71 |

application

- Smooth Turning System: Water pump outlet, compressor piping, 45° turn reduces water hammer impact by 60%, protecting valves and instruments.

- Long-distance Inclined Piping: Mine conveying pipes, slope fire protection piping, replacing multiple 90° elbows to achieve smooth turns.

- Precision spatial adjustment: Behind control cabinets/instrument panels, small-sized elbows (e.g., 1/4″) enable precise adjustment of pipeline angles in extremely narrow spaces.

- Energy-efficient fluid systems: HVAC chilled water pipes reduce turbulence pressure loss, lowering system energy consumption by 15%.

- High-pressure safety upgrades: Class 300-rated for hydraulic stations and air compressor piping, withstanding 2000 psi impact pressure.

advantages

- Golden Angle Design:

- 45° bend optimizes space and flow efficiency, with pressure loss only 40% of a 90° elbow;

- Extremely short center distance (e.g., 1/2″ Class 150 is only 22.4mm), saving installation space.

- Dual pressure ratings cover all requirements:

- Class 150: General-purpose, temperature range -29°C to 66°C, pressure rating 300 psi;

- Class 300: High-pressure specialized, 2000 psi safety margin increased by 80%.

- Seismic-resistant long-life structure:

- Ductile iron (ASTM A197) resists mechanical impact, with a lifespan 50% longer than ordinary cast iron;

- NPT threaded double seals, UL/FM certified for leak prevention.

- Full environmental protection:

- Hot-dip galvanized coating with salt spray resistance >900 hours, suitable for coastal/chemical plant environments;

- Black iron version with phosphating treatment, suitable for rust prevention in dry environments.

- 1-minute quick installation: Manual tightening completes the process, 20 times faster than welding.

packing

- Threaded Armor Protection:

- Threaded ends are coated with long-lasting anti-rust grease, covered with silicone caps and double-layered heat-shrinkable film for protection.

- Elbow bodies are wrapped in pearl cotton and embedded in pressure-resistant EPS molds to prevent breakage.

- Pressure-graded intelligent packaging:

- Class 150: Blue-labeled boxes, 40 pieces per box (≤1″), paper dividers + humidity indicator cards;

- Class 300: Red-labeled box, 15 pieces per box, with a “high-pressure lightning” warning label printed on the box.

- Revolutionary solution for large items:

- ≥3″ elbows use recyclable steel frame boxes with swivel casters on the bottom;

- Built-in NFC chip, scan to obtain installation torque parameters.

- Error-proofing traceability system:

- Product casting with “CL150/300” pressure rating;

- Outer box labeled with a 45° angle to avoid confusion with 90° elbows.

Available size

| SIZE | A | ||

| INCH | DN | MM | MM |

| 1/2″ | 15 | 21.3 | 22.4 |

| 3/4″ | 20 | 26.7 | 24.9 |

| 1″ | 25 | 33.4 | 28.5 |

| 1-1/4″ | 32 | 42.4 | 32.8 |

| 1-1/2″ | 40 | 48.3 | 36.3 |

| 2″ | 50 | 60.3 | 42.7 |

| 2-1/2″ | 65 | 73 | 49.5 |

| 3″ | 80 | 88.9 | 55.1 |

| 4″ | 100 | 114.3 | 66.3 |

| 6″ | 150 | 168.3 | 87.9 |

| 1/4” | 8 | 13.7 | 20.6 |

| 3/8” | 10 | 17.1 | 22.4 |

| 1/2” | 15 | 21.3 | 25.4 |

| 3/4” | 20 | 26.7 | 28.7 |

| 1” | 25 | 33.4 | 33.3 |

| 1-1/4” | 32 | 42.2 | 38.1 |

| 1-1/2” | 40 | 48.3 | 42.9 |

| 2” | 50 | 60.3 | 50.8 |

| 2-1/2” | 65 | 73 | 57.2 |

| 3” | 80 | 88.9 | 63.5 |

| 4” | 100 | 114.3 | 71 |

- Smooth Turning System: Water pump outlet, compressor piping, 45° turn reduces water hammer impact by 60%, protecting valves and instruments.

- Long-distance Inclined Piping: Mine conveying pipes, slope fire protection piping, replacing multiple 90° elbows to achieve smooth turns.

- Precision spatial adjustment: Behind control cabinets/instrument panels, small-sized elbows (e.g., 1/4″) enable precise adjustment of pipeline angles in extremely narrow spaces.

- Energy-efficient fluid systems: HVAC chilled water pipes reduce turbulence pressure loss, lowering system energy consumption by 15%.

- High-pressure safety upgrades: Class 300-rated for hydraulic stations and air compressor piping, withstanding 2000 psi impact pressure.

- Golden Angle Design:

- 45° bend optimizes space and flow efficiency, with pressure loss only 40% of a 90° elbow;

- Extremely short center distance (e.g., 1/2″ Class 150 is only 22.4mm), saving installation space.

- Dual pressure ratings cover all requirements:

- Class 150: General-purpose, temperature range -29°C to 66°C, pressure rating 300 psi;

- Class 300: High-pressure specialized, 2000 psi safety margin increased by 80%.

- Seismic-resistant long-life structure:

- Ductile iron (ASTM A197) resists mechanical impact, with a lifespan 50% longer than ordinary cast iron;

- NPT threaded double seals, UL/FM certified for leak prevention.

- Full environmental protection:

- Hot-dip galvanized coating with salt spray resistance >900 hours, suitable for coastal/chemical plant environments;

- Black iron version with phosphating treatment, suitable for rust prevention in dry environments.

- 1-minute quick installation: Manual tightening completes the process, 20 times faster than welding.

- Threaded Armor Protection:

- Threaded ends are coated with long-lasting anti-rust grease, covered with silicone caps and double-layered heat-shrinkable film for protection.

- Elbow bodies are wrapped in pearl cotton and embedded in pressure-resistant EPS molds to prevent breakage.

- Pressure-graded intelligent packaging:

- Class 150: Blue-labeled boxes, 40 pieces per box (≤1″), paper dividers + humidity indicator cards;

- Class 300: Red-labeled box, 15 pieces per box, with a “high-pressure lightning” warning label printed on the box.

- Revolutionary solution for large items:

- ≥3″ elbows use recyclable steel frame boxes with swivel casters on the bottom;

- Built-in NFC chip, scan to obtain installation torque parameters.

- Error-proofing traceability system:

- Product casting with “CL150/300” pressure rating;

- Outer box labeled with a 45° angle to avoid confusion with 90° elbows.

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.