HOT PRODUCTS TAGS

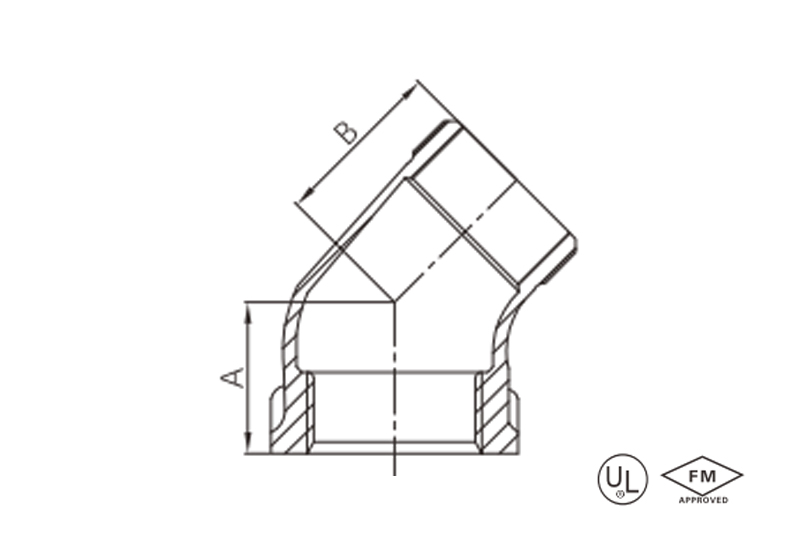

Malleable iron 45° street elbow

·Standard: ANSI/ASME B16.3

UL/FM

·Material: Malleable iron ASTM A197

·Thread: NPT

·W. pressure: Class 150, 300 psi (-29°C to 66°C)

Class 300, 1000 / 1500 / 2000 psi

(-29°C to 66°C)

·Surface: Black iron / hot dip galvanized

·Size Range: 1/2″ —4″ (Class 150)

3/4″—1-1/2″ (Class 300)

description

Malleable iron 45° street elbow, with firm socket connection, suitable angle, pressure resistance and wear resistance, quick installation.

Specification

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ | 15 | 21.3 | 22.4 | 29.2 |

3/4″ | 20 | 26.7 | 24.9 | 32.8 |

1″ | 25 | 33.4 | 28.5 | 37.3 |

1-1/4″ | 32 | 42.2 | 32.8 | 43.4 |

1-1/2″ | 40 | 48.3 | 36.3 | 47.8 |

2″ | 50 | 60.3 | 42.7 | 56.4 |

2-1/2″ | 65 | 73 | 49.5 | 65.3 |

3″ | 80 | 88.9 | 55.1 | 76.2 |

4″ | 100 | 114.3 | 66.3 | 94 |

3/4” | 20 | 26.7 | 28.7 | 39.6 |

1” | 25 | 33.4 | 33.3 | 46 |

1-1/4″ | 32 | 42.2 | 38.1 | 54.1 |

1-1/2″ | 40 | 48.3 | 42.9 | 58.7 |

application

- Equipment corner connections: For wall-mounted equipment such as boilers and heat exchangers, external threads connect directly to the equipment ports, while internal threads connect to the piping. A 45° bend perfectly avoids wall obstacles.

- Precision piping layout for instrument panels: On the back of control cabinets and electrical panels, small-sized elbows (e.g., 1/2″) achieve smooth bends in a 3cm limited space, eliminating pipe twisting.

- High-pressure energy-saving system: Class 300-grade piping for air compressors (rated for 2000 psi pressure), with a 45° design reducing pressure loss by 40% and minimizing energy waste.

- Compact connections for corrosive environments: Hot-dip galvanized plates are used in ship engine rooms and chemical plant reagent pipelines to replace flange connections and prevent rusting.

- Emergency repair and renovation: Local adjustments to the pipeline system can be quickly completed in 20 minutes using threaded connections, without the need for production shutdowns or welding.

advantages

- Dual Thread Space Magician:

- External Thread (Male) End: Directly connects to equipment interfaces;

- Internal Thread (Female) End: Connects to pipeline systems, eliminating the need for one adapter and reducing leakage risk by 60%.

- Dual Pressure Rating Precision Coverage:

- Class 150: General-purpose, 300 psi pressure rating, suitable for a wide temperature range of -29°C to 66°C;

- Class 300: High-pressure specialized (e.g., 1-1/2″ with 1500 psi pressure rating), 80% increase in safety redundancy.

- Earthquake-resistant long-life design:

- Forged cast iron (ASTM A197) resists mechanical impact, with a 50% longer lifespan than ordinary cast iron;

- NPT tapered thread self-sealing, UL/FM certified leak-proof.

- All-environment defense shield:

- Hot-dip galvanized coating with salt spray resistance >900 hours, suitable for coastal/industrial corrosive environments;

- Black iron version with phosphating treatment, suitable for dry environments.

- 70-second rapid installation: Manual tightening completes the process, saving 5 hours per node compared to welding.

packing

- Threaded Armor-Grade Protection:

- External threaded sleeves with silicone anti-collision caps, internal threads coated with food-grade anti-rust oil + heat-shrinkable film sealing;

- Main body wrapped in pearl cotton, embedded in high-pressure-resistant EPS molds to prevent transportation breakage.

- Pressure-Sensitive Smart Packaging:

- Class 150: Blue-labeled boxes, 35 pieces per box (≤1″), honeycomb paper trays with dividers + humidity indicator cards;

- Class 300: Red-labeled box, 10 pieces per box (high-pressure components individually sealed), box marked with “high-pressure lightning” symbol.

- Large-item special solution:

- ≥2″ elbows use reusable steel frame boxes with casters on the bottom for direct on-site towing;

- Boxes embedded with NFC chips for mobile phone access to installation videos.

- Dual safety measures:

- Products are cast with “CL150/300” pressure rating markings;

- Outer boxes are labeled with a 45° turning diagram, with arrows indicating “external thread → equipment, internal thread → pipeline.”

Available size

SIZE | A | B | ||

INCH | DN | MM | MM | MM |

1/2″ | 15 | 21.3 | 22.4 | 29.2 |

3/4″ | 20 | 26.7 | 24.9 | 32.8 |

1″ | 25 | 33.4 | 28.5 | 37.3 |

1-1/4″ | 32 | 42.2 | 32.8 | 43.4 |

1-1/2″ | 40 | 48.3 | 36.3 | 47.8 |

2″ | 50 | 60.3 | 42.7 | 56.4 |

2-1/2″ | 65 | 73 | 49.5 | 65.3 |

3″ | 80 | 88.9 | 55.1 | 76.2 |

4″ | 100 | 114.3 | 66.3 | 94 |

3/4” | 20 | 26.7 | 28.7 | 39.6 |

1” | 25 | 33.4 | 33.3 | 46 |

1-1/4″ | 32 | 42.2 | 38.1 | 54.1 |

1-1/2″ | 40 | 48.3 | 42.9 | 58.7 |

- Equipment corner connections: For wall-mounted equipment such as boilers and heat exchangers, external threads connect directly to the equipment ports, while internal threads connect to the piping. A 45° bend perfectly avoids wall obstacles.

- Precision piping layout for instrument panels: On the back of control cabinets and electrical panels, small-sized elbows (e.g., 1/2″) achieve smooth bends in a 3cm limited space, eliminating pipe twisting.

- High-pressure energy-saving system: Class 300-grade piping for air compressors (rated for 2000 psi pressure), with a 45° design reducing pressure loss by 40% and minimizing energy waste.

- Compact connections for corrosive environments: Hot-dip galvanized plates are used in ship engine rooms and chemical plant reagent pipelines to replace flange connections and prevent rusting.

- Emergency repair and renovation: Local adjustments to the pipeline system can be quickly completed in 20 minutes using threaded connections, without the need for production shutdowns or welding.

- Dual Thread Space Magician:

- External Thread (Male) End: Directly connects to equipment interfaces;

- Internal Thread (Female) End: Connects to pipeline systems, eliminating the need for one adapter and reducing leakage risk by 60%.

- Dual Pressure Rating Precision Coverage:

- Class 150: General-purpose, 300 psi pressure rating, suitable for a wide temperature range of -29°C to 66°C;

- Class 300: High-pressure specialized (e.g., 1-1/2″ with 1500 psi pressure rating), 80% increase in safety redundancy.

- Earthquake-resistant long-life design:

- Forged cast iron (ASTM A197) resists mechanical impact, with a 50% longer lifespan than ordinary cast iron;

- NPT tapered thread self-sealing, UL/FM certified leak-proof.

- All-environment defense shield:

- Hot-dip galvanized coating with salt spray resistance >900 hours, suitable for coastal/industrial corrosive environments;

- Black iron version with phosphating treatment, suitable for dry environments.

- 70-second rapid installation: Manual tightening completes the process, saving 5 hours per node compared to welding.

- Threaded Armor-Grade Protection:

- External threaded sleeves with silicone anti-collision caps, internal threads coated with food-grade anti-rust oil + heat-shrinkable film sealing;

- Main body wrapped in pearl cotton, embedded in high-pressure-resistant EPS molds to prevent transportation breakage.

- Pressure-Sensitive Smart Packaging:

- Class 150: Blue-labeled boxes, 35 pieces per box (≤1″), honeycomb paper trays with dividers + humidity indicator cards;

- Class 300: Red-labeled box, 10 pieces per box (high-pressure components individually sealed), box marked with “high-pressure lightning” symbol.

- Large-item special solution:

- ≥2″ elbows use reusable steel frame boxes with casters on the bottom for direct on-site towing;

- Boxes embedded with NFC chips for mobile phone access to installation videos.

- Dual safety measures:

- Products are cast with “CL150/300” pressure rating markings;

- Outer boxes are labeled with a 45° turning diagram, with arrows indicating “external thread → equipment, internal thread → pipeline.”

Get Your Custom Steel Pipe Quote Today!

Provide us with your project details (like application, specifications, quantity). Our experienced team will respond with a tailored solution and competitive quote within 24 business hours.